Machine and method for forming containers from blanks

A technology for blanks, machines, applied in the field of machines and methods for forming containers from blanks, which can solve the problems of unsuitability for loose items, lack of precision, slowness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

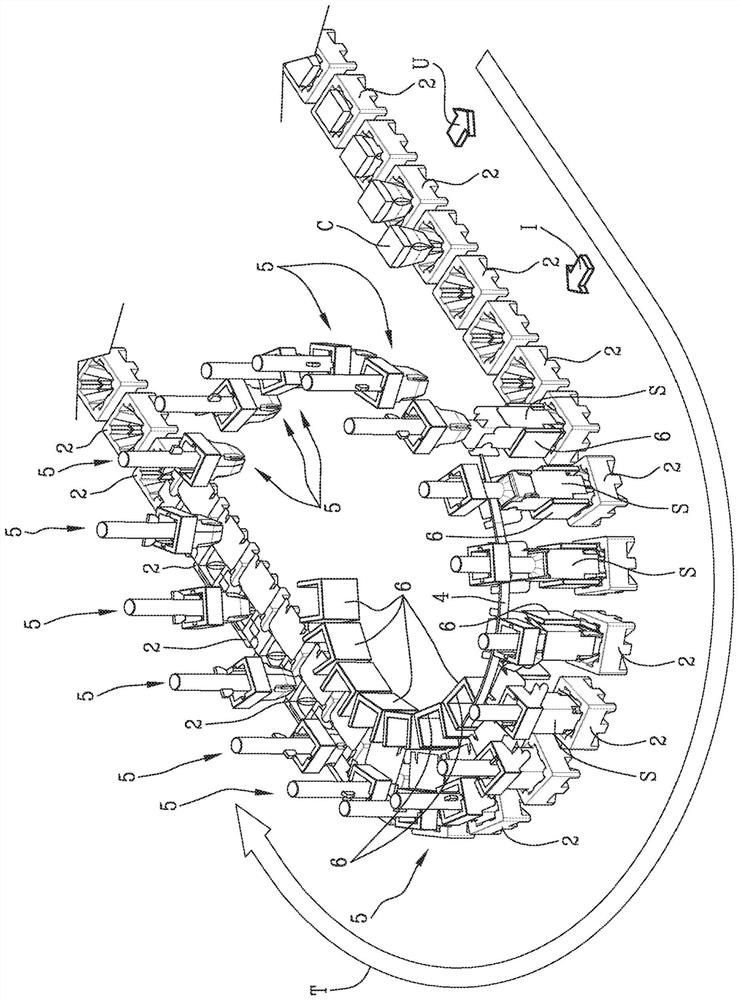

[0032] With reference to the drawings, the reference number 1 designates as a whole a machine for forming containers C from blanks S; in the following reference is made to preglued tubular blanks S without loss of generality.

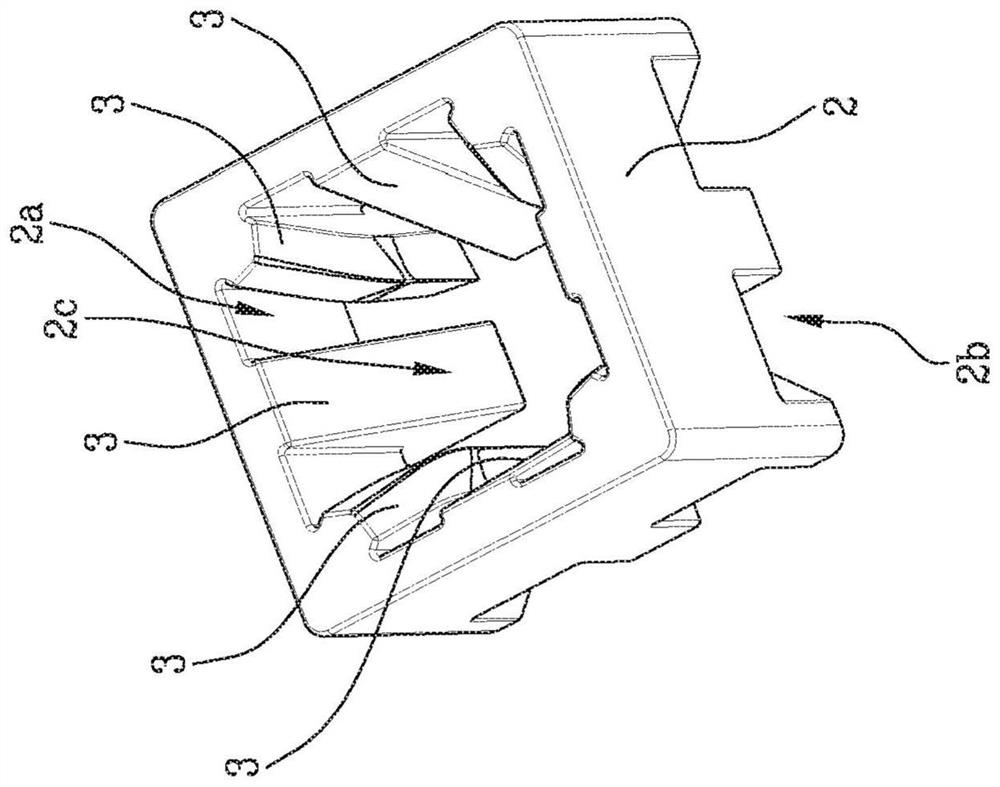

[0033] "Tubular blank" S means such as for example Figure 4A Shown is a blank having a body S1 defining a side wall L, a top opening AS and a bottom opening AI, each opening being provided with a respective end flap A. The term "preglued" denotes a blank that is initially flat and then folded, glued and flattened to define a partially formed blank ready to assume the shape described above. In other words, before entering the machine 1 the flat blank is folded and glued so that when processed its flattened shape will readily adopt a tubular shape with eg a substantially rectangular cross-section.

[0034] exist Figure 4A in (and in Figure 4B ) is shown by way of example with four side walls L and four end flaps A at its top opening AS and four end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com