Rubber pipeline flaring device for new energy automobile wire harness arrangement

A technology of new energy vehicles and rubber pipes, applied in the field of expanders, can solve the problems of automatic clamping, automatic heating, low efficiency, etc., and achieve the effect of easy connection and convenient expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

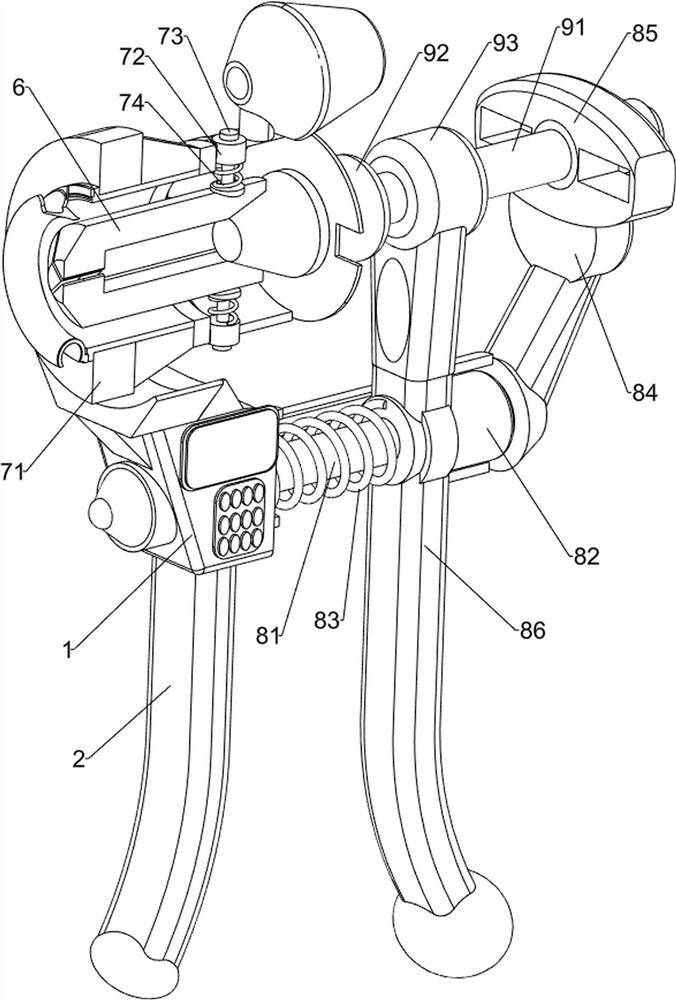

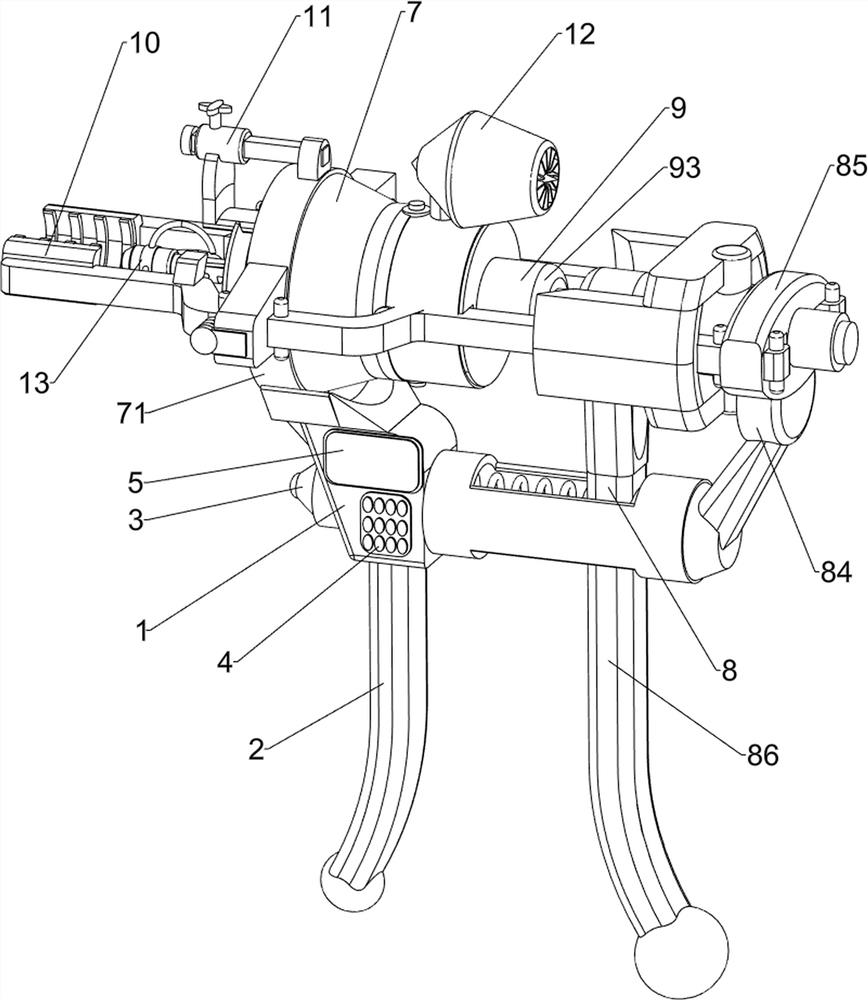

[0027] A kind of rubber pipe expander for new energy vehicle wiring harness arrangement, such as Figure 1-2 As shown, it includes a fixed seat 1, a handle 2, a key board 4, an LCD display 5, an expansion plate 6, a guide mechanism 7, a driving mechanism 8 and an expansion mechanism 9, and the bottom of the fixed seat 1 is provided with a handle 2, which is fixed The lower part of the front side of the seat 1 is provided with a keypad 4, the upper part of the front side of the fixed seat 1 is provided with an LCD display 5, the top of the fixed seat 1 is provided with a guide mechanism 7, and the parts of the guide mechanism 7 are provided with a plurality of expansion plates 6, and the fixed seat 1 The right side is provided with a driving mechanism 8, and the driving mechanism 8 is provided with a stretching mechanism 9.

[0028] The guide mechanism 7 includes a fixed tube 71, a guide sleeve 72, a guide rod 73 and a first spring 74. The top of the fixed base 1 is provided wi...

Embodiment 2

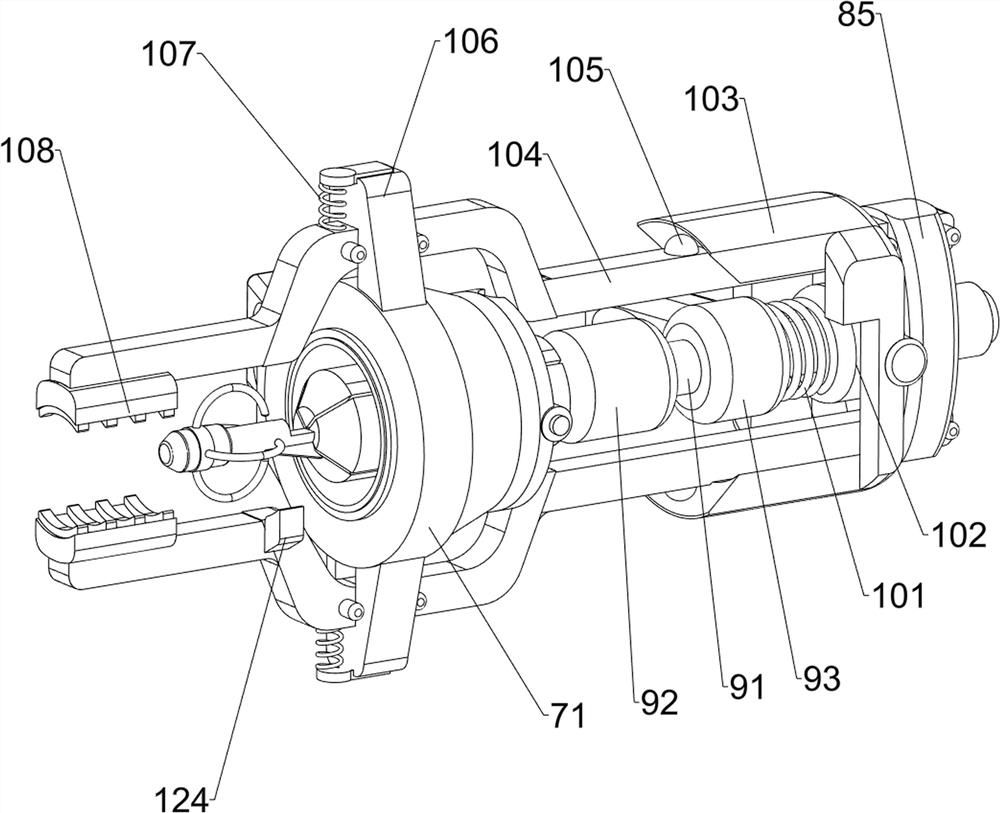

[0033] On the basis of Example 1, such as Figure 3-7 As shown, a clamping mechanism 10 is also included, and the clamping mechanism 10 includes a third spring 101, a connecting pipe 102, an inclined plate 103, a transmission plate 104, a ball 105, a guide block 106, a fourth spring 107 and an inner tooth plate 108, the right side of the drive sleeve 93 is provided with a third spring 101, the right side of the third spring 101 is provided with a connecting pipe 102, the connecting pipe 102 and the guide post 91 are slidingly connected, the connecting pipe 102 is provided with a slanted plate 103, and the fixed pipe 71 front and rear sides are all connected with guide block 106, all slide type is connected with drive plate 104 between guide block 106 and guide plate 85, are all provided with the 4th spring 107 between drive plate 104 and guide block 106, drive plate 104 left Both sides are provided with internal gear plates 108, and the outer sides of the transmission plate 10...

Embodiment 3

[0042] On the basis of Example 1, such as figure 1 , image 3 and Figure 4 As shown, it also includes a control box 3, the fixed seat 1 is provided with a control box 3, the control box 3 includes a battery, a control module and a power module, the battery supplies power for the entire device, and the power module is connected to a main power switch through a line , the control module and the power module are electrically connected, and the control module and the photoelectric sensor 124 are electrically connected; the keypad 4 is provided with a first setting key, a second setting key, plus one key, minus one key, confirmation key and start key; the control module is connected with a DS1302 clock circuit and a 24C02 circuit; the first setting key, the second setting key, plus one key, minus one key, confirmation key and start key are all electrically connected with the control module, and the hot air blower 122 and The control module is connected through peripheral circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com