Battery cell shell entering equipment

A cell and equipment technology, applied in the field of cell-inserting equipment, can solve the problems of low production efficiency and labor-intensive production of cylindrical cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] In the cylindrical battery production line, after the flattening process of the tabs of the battery cells is completed, the battery cells need to be put into the shell;

[0052] However, in the current cylindrical cell production line, a large number of manual operations are required in the process of putting the cell into the shell, especially the loading of the battery cell, the loading of the steel shell and the subsequent battery unloading; making the production cycle too long, The overall production efficiency is low, while increasing the input of human resources;

[0053]In order to solve the above technical problems, this embodiment provides the following technical solutions:

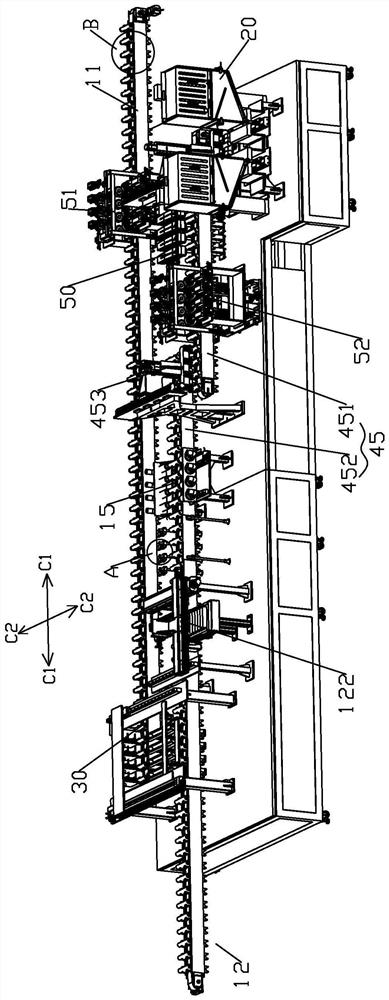

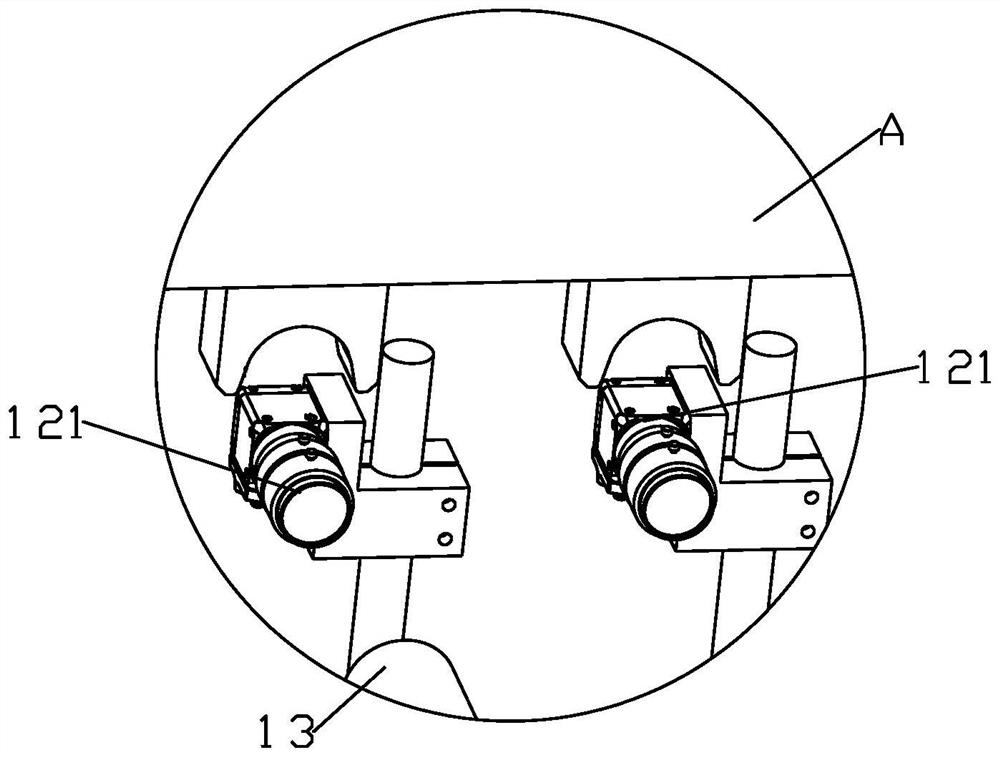

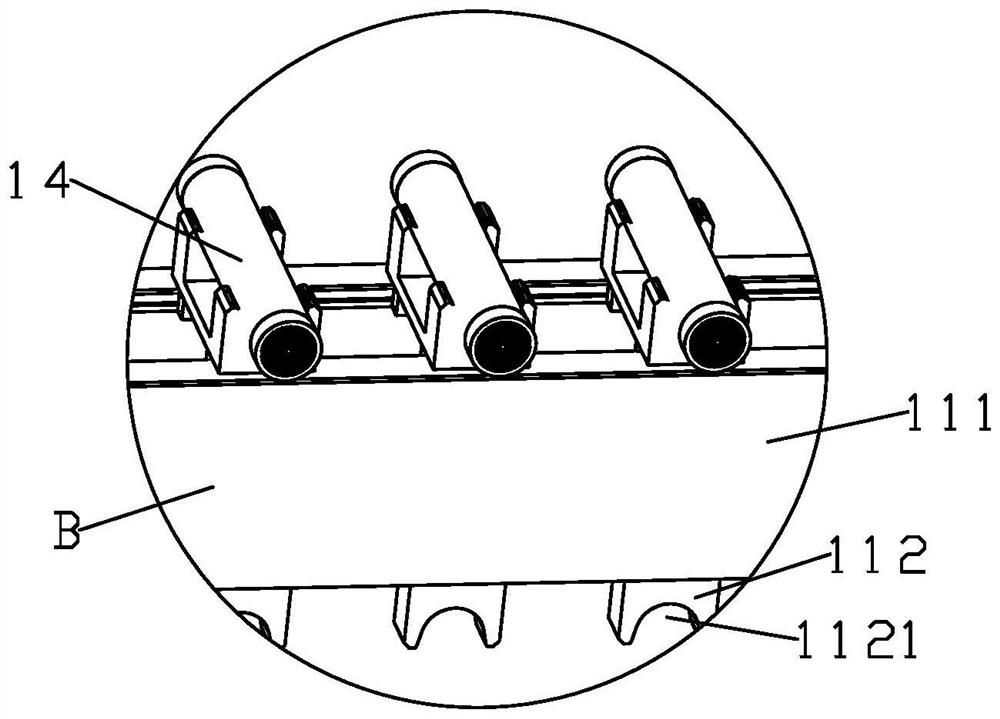

[0054] Specifically, see Figure 1-9 , the present embodiment provides a kind of electric core casing equipment, including the first conveying device 11, the second conveying device 12;

[0055] Specifically, the first conveying device 11 conveys the electric core 14 along the first dire...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap