Aluminum beam top vertical rod connector

A technology of connectors and poles, applied in the field of connectors, can solve problems such as inconvenient use and inability to adjust, and achieve the effect of easy adjustment, easy fixing or loosening of items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

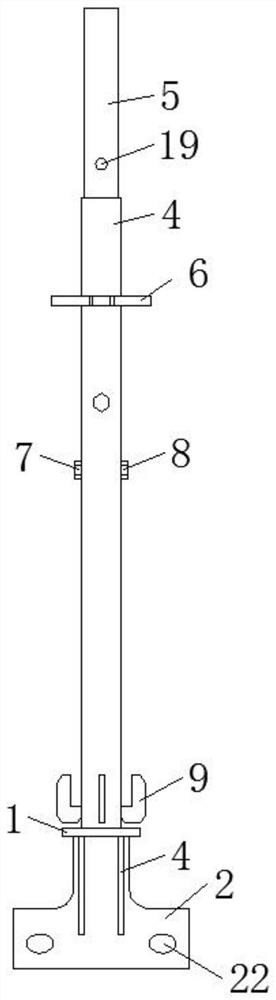

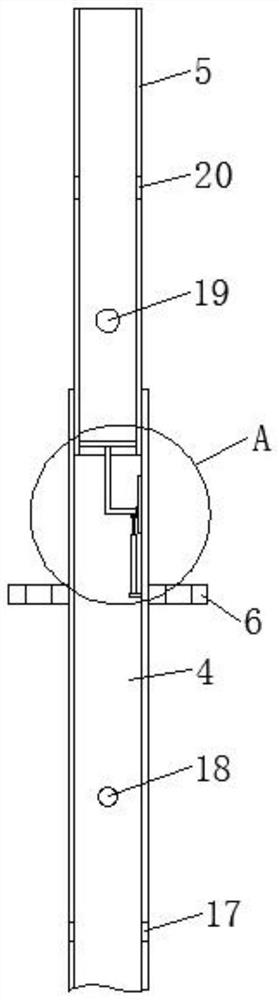

Embodiment 1

[0026] Such as Figure 1-5 As shown, a connecting head of a pole at the top of an aluminum beam includes a top plate 1, a side plate 2, a gusset plate 3, a connecting pipe 4, a connecting head 5, a circular connecting plate 6, a hexagonal bolt 7, a lock nut 8 and a fixing The plate 9, the side plate 2 is arranged at the bottom of the bottom plate 1, the connecting pipe 4 is arranged at the top of the top plate 1, the top of the gusset plate 3 is connected with the bottom of the top plate 1, the side wall of the gusset plate 3 is connected with the side plate 2, through the gusset plate 3 and The connection between the top plate 1 and the side plate 2 is more stable, the circular connecting plate 6 is sleeved on the outer wall of the connecting pipe 4, the fixed plate 9 is connected to the bottom of the outer wall of the connecting pipe 4, the connecting head 5 is movable in the connecting pipe 4, and the inner side of the connecting pipe 4 The top of the wall is provided with ...

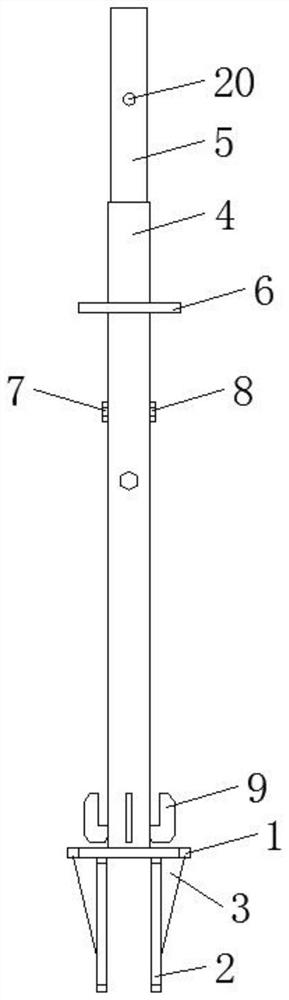

Embodiment 2

[0029] Such as figure 1 , Figure 6 As shown, a connecting head of a pole at the top of an aluminum beam includes a top plate 1, a side plate 2, a gusset plate 3, a connecting pipe 4, a connecting head 5, a circular connecting plate 6, a hexagonal bolt 7, a lock nut 8 and a fixing Plate 9, side plate 2 is set at the bottom of bottom plate 1, connecting pipe 4 is set at the top of top plate 1, the top of gusset plate 3 is connected to the bottom of top plate 1, the side wall of gusset plate 3 is connected to side plate 2, and 6 sets of circular connecting plates Located on the outer wall of the connecting pipe 4, the fixing plate 9 is connected to the bottom of the outer wall of the connecting pipe 4, the connecting head 5 is movably arranged in the connecting pipe 4, and the outer wall of the connecting pipe 4 is provided with a strip-shaped through hole 23 on the side close to the fixing plate 9, and the connecting pipe 4 is provided with the disk 24 of movable connection, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com