Distribution strategy for joint debugging of AGV based on scheduling system and multi-storage-position system

A technology of scheduling system and distribution strategy, applied in the field of warehousing system, can solve problems such as low handling efficiency and increased energy cost, and achieve the effect of reducing energy consumption, reducing driving distance, improving utilization rate and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

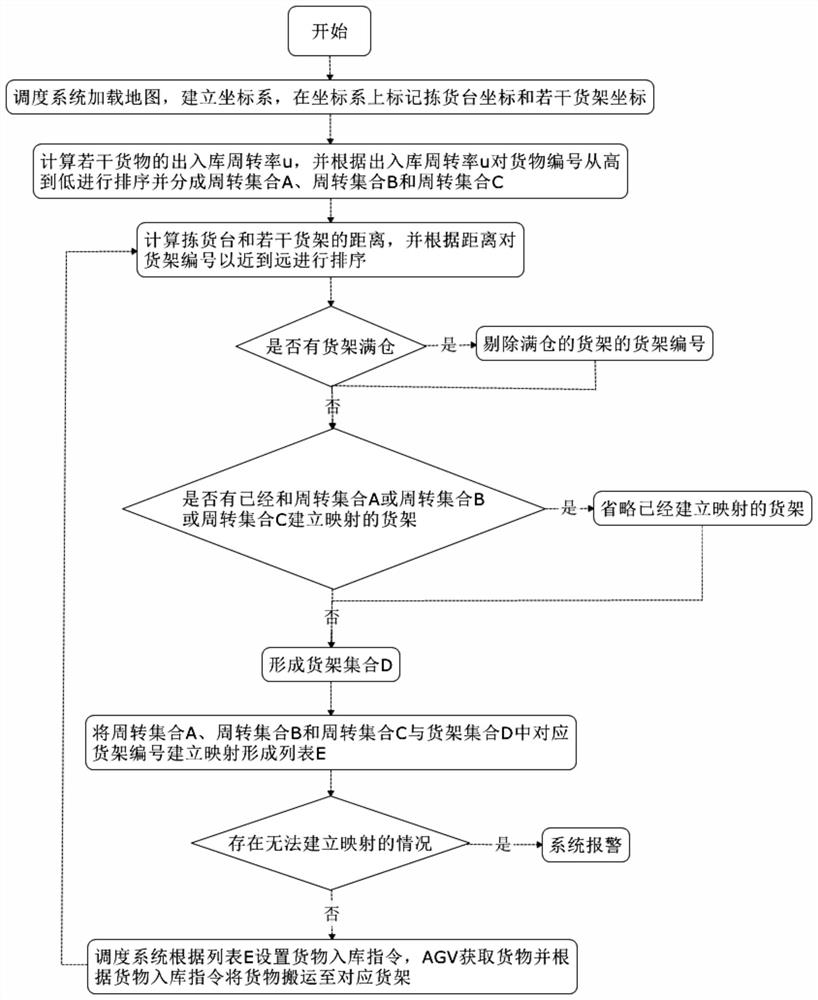

[0039] see figure 1 , the distribution strategy of the joint debugging AGV based on the dispatching system and the multi-storage system of the present embodiment includes the following steps:

[0040] (1) The dispatching system loads the map, establishes a coordinate system, and marks the coordinates of the picking platform and several shelf coordinates on the coordinate system;

[0041] (2) Calculate the inbound and outbound turnover rate u of several goods, and sort the goods numbers from high to low according to the inbound and outbound turnover rate u, and divide them into turnover set A, turnover set B and turnover set C, among which goods with high turnover rate are divided To turnover set A, the goods with medium turnover rate are divided into turnover set B, and the goods with low turnover rate are divided into turnover set C;

[0042] (3) Calculate the distance between the picking platform and several shelves, and sort the shelf numbers from near to far according to ...

Embodiment 2

[0073] As an improved solution of Embodiment 1 of this embodiment, the difference is that in step (4), the method of establishing a mapping to form list E is replaced by:

[0074] Divide the shelves in the shelf set D into three subsets D1, D2 and D3, wherein the number of shelves in the subset D1 > the number of shelves in the subset D2 ≥ the number of shelves in the subset D3;

[0075] The turnover set A is mapped with the subset D1, the turnover set B is mapped with the subset D2, and the turnover set C is mapped with the subset D3.

[0076] The following shows the expressions of the contents recorded in one of turnover set A, turnover set B, turnover set C, shelf set D and list E:

[0077] Turnover set A: Goods 008, Goods 005, Goods 001, Goods 011.

[0078] Turnover set B: Goods 002, Goods 003, Goods 004, Goods 006.

[0079] Turnover collection C: Goods 009, Goods 007, Goods 010.

[0080] Shelf collection D: shelf A3, shelf A2, shelf A1, shelf A4, shelf A5, shelf A7, sh...

Embodiment 3

[0085] As an improved solution of Embodiment 1 of this embodiment, the difference is that in step (4), the method of establishing a mapping to form list E is replaced by:

[0086] Take the top 3 shelves in the shelf set D, establish a mapping between the turnover set A and the shelf number of the first-ranked shelf, establish a mapping between the turnover set B and the shelf number of the second-ranked shelf, and establish a mapping between the turnover set C and the third-ranked shelf The shelf number of each shelf is used to establish a mapping; after any shelf is full, the remaining shelves in the shelf set D are sequentially supplemented with the turnover set corresponding to the full shelf to establish a new mapping.

[0087] In this embodiment, as the progress of the work progresses, the first-ranked shelf in the shelf set D is full (assigned to the turnover set A), and the second-ranked shelf and the third-ranked shelf are assigned to the turnover set B and the turnover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com