Knitted fabric containing real silk, processing equipment and weaving method

A technology of knitted fabrics and real silk, which is applied in the field of knitted fabrics and can solve the problems that silk fabrics cannot be machine washed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

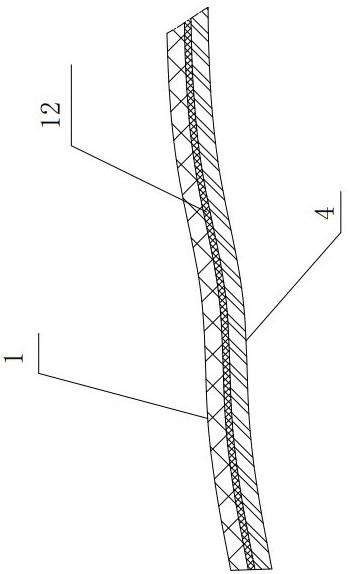

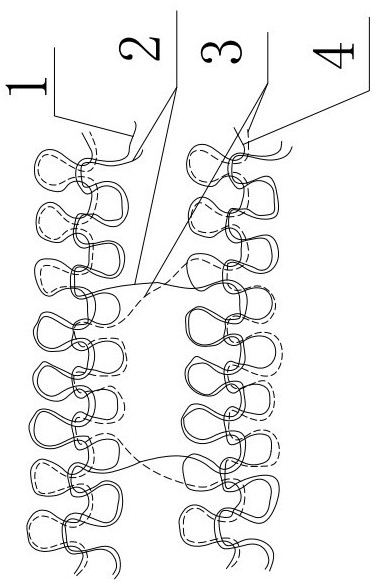

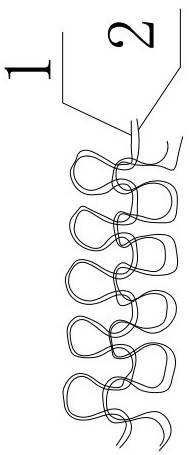

[0030] Depend on figure 1 combine Figure 2-5 As shown, a knitted fabric containing real silk without ironing and cutting according to the shape, one side is real silk 1 plus A spandex filament 2 or B spandex filament 3, and the other side is knitted with nylon filament 4 plus B spandex filament 3 or A spandex filament It is formed by connecting A spandex yarn 2 and B spandex yarn 3 . Specifically, the spandex yarn A and the spandex yarn B cooperate together to form the connecting layer 12 , more specifically, the spandex yarn A and the spandex yarn B are exchanged and connected to each other to form the connecting layer 12 . attached figure 1 The connection layer 12 is the connection layer connecting the silk surface and the nylon surface, and is composed of A spandex filament and B spandex filament. A spandex filament and B spandex filament do not speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com