Flat enameled wire painting mold and paint film coating process method

A technology of enameled wire and mould, which is applied in the direction of conductor/cable insulation, etc. It can solve problems such as complexity, uneven insulation layer, and thinning of chamfered area, and achieve the effect of large and uniform coating liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

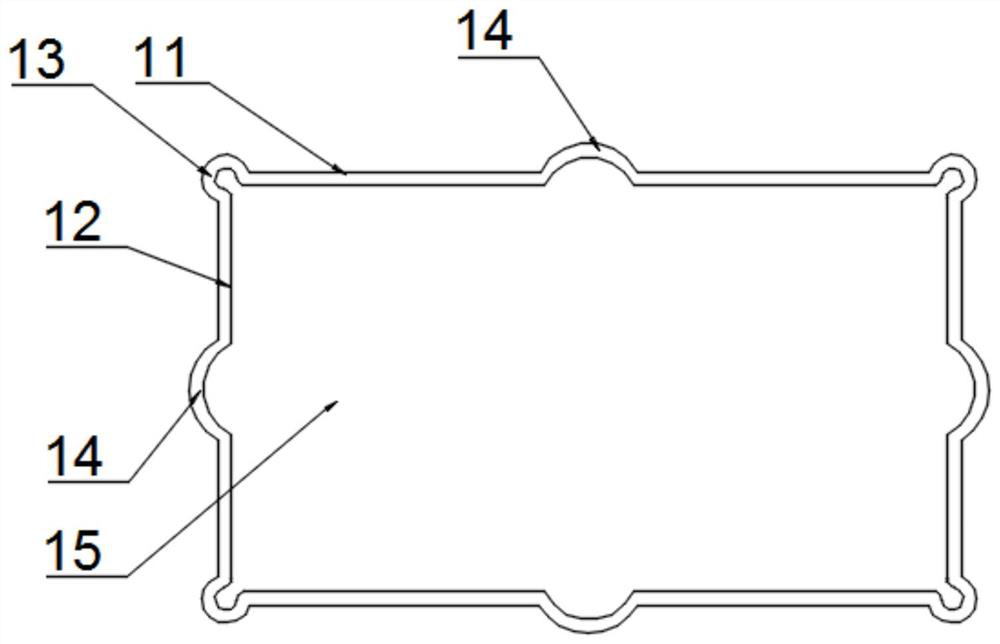

[0037] see figure 2 and image 3 , a flat enameled wire painting mold, including a mold part 1, the mold part 1 is provided with an insertion hole 15 that allows the flat wire to pass through; the mold part 1 includes two long side parts 11, two short side parts 12 and four round convex parts 13, the two long side parts 11, two short side parts 12 and four round convex parts 13 surround a rectangular structure; the round convex parts 13 connect adjacent long side parts 11 And the short side portion 12; the middle positions of the long side portion 11 and the short side portion 12 are both provided with an outwardly recessed concave portion 14.

[0038] Specifically, the circular convex portion 13 is in the shape of a long arc; the concave depth of the circular convex portion and the concave portion is 5-15 μm; in this embodiment, it is preferably 10 μm;

[0039] Specifically, the curvature of the circular convex portion 13 is greater than the curvature of the flat enameled ...

Embodiment 2

[0042] see figure 2 , Figure 4-7, a flat enameled wire painting mold, including a mold part 1, the mold part 1 is provided with an insertion hole 15 that allows the flat wire to pass through; the mold part 1 includes two long side parts 11, two short side parts 12 and four round convex parts 13, the two long side parts 11, two short side parts 12 and four round convex parts 13 surround a rectangular structure; the round convex parts 13 connect adjacent long side parts 11 And the short side portion 12; the middle positions of the long side portion 11 and the short side portion 12 are both provided with an outwardly recessed concave portion 14.

[0043] Specifically, the circular convex portion 13 is in the shape of a long arc;

[0044] Specifically, the curvature of the circular convex portion 13 is greater than the curvature of the flat enameled wire;

[0045] Specifically, the concave portion 14 is arc-shaped, and the curvature of the concave portion 14 is smaller than t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth of depression | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com