Universal quick connecting and disconnecting connector device for large pipeline

A joint device and pipeline technology, applied in the direction of pipe/pipe joint/pipe fitting, adjustable connection, passing element, etc., can solve the problem that the volume of the locking device cannot be provided with sufficient locking force, the time-consuming and laborious connection and disassembly, and the existence of debris noise and other problems, to achieve the effect of eliminating alignment work, reducing volume, and shortening connection and disassembly time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

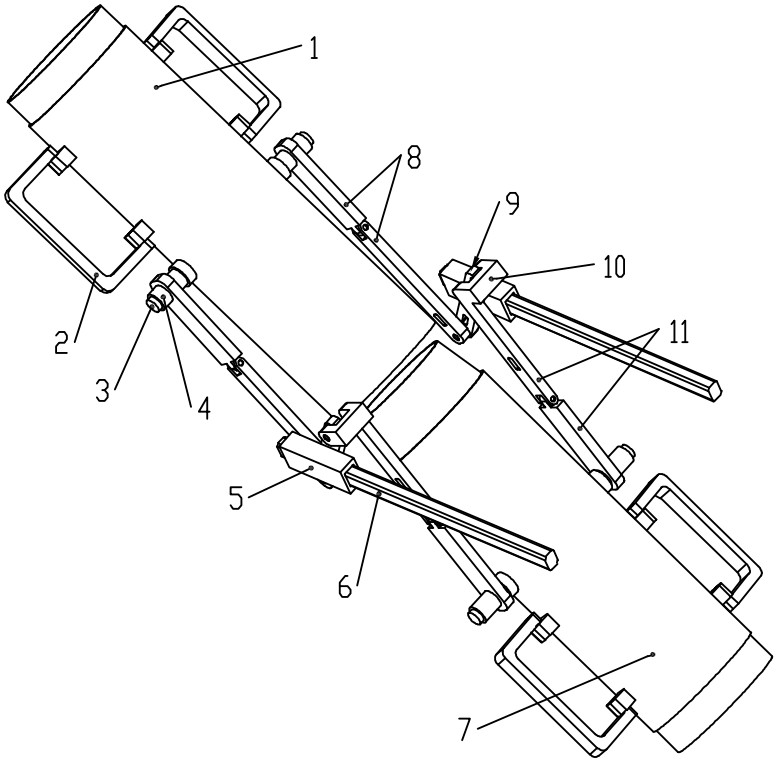

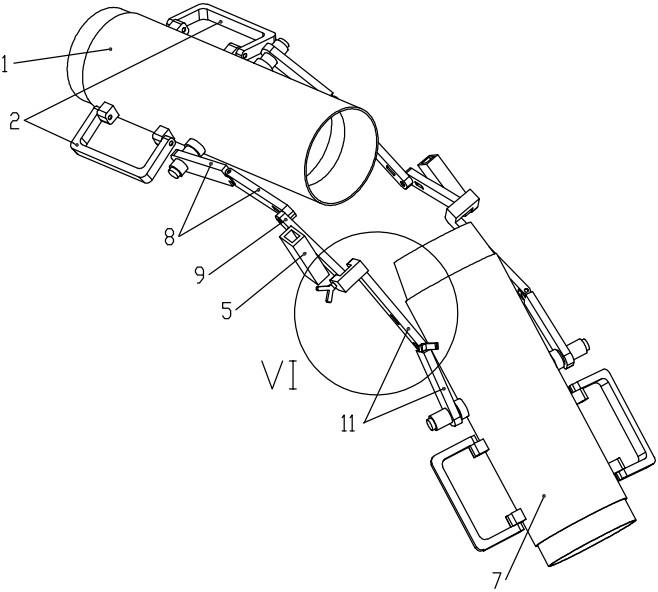

[0037] as attached Figure 1-9 As shown, in order to clearly demonstrate the principle and working process of the present invention, this embodiment provides a more typical implementation solution, but the following cases cannot represent all solutions of the present invention.

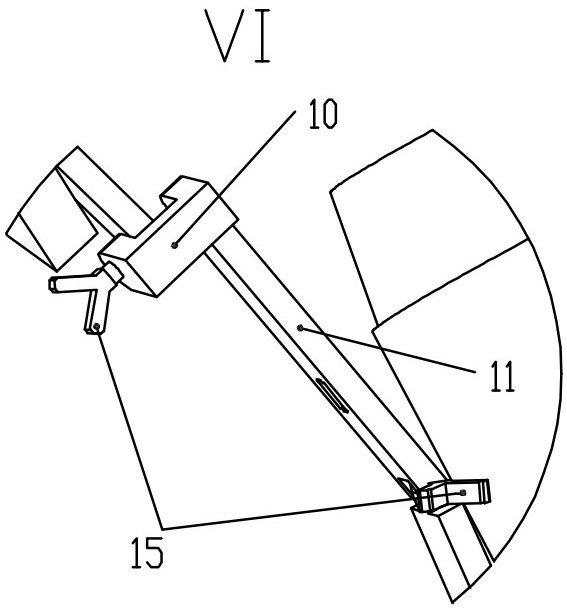

[0038] Among them, such as Figure 9 As shown, one end of the C connecting rod 11 has a limit projection 10, the limit projection 10 enables the C link 11 to extend laterally, and there is also a hole for hinged connection on the limit projection 10, and the limit projection 10 participates in to the hinged connection between the A connecting rod 8 and the C connecting rod 11 and the B connecting rod 9; specifically, a hinge connection scheme as shown in the illustration is that the C connecting rod connects with the B connecting rod through the hole on its limit protrusion 10 One end of the connecting rod 9 is hinged, and the other end of the B connecting rod is hinged with one end of the A connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com