Two-dimensional centroid measuring device and measuring method thereof

A measuring device and a two-dimensional center of mass technology, which is applied in the direction of measuring devices, machine/structural component testing, static/dynamic balance testing, etc., can solve the problems of difficulty in measuring the center of mass, low measurement accuracy, etc., and achieve safe use and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

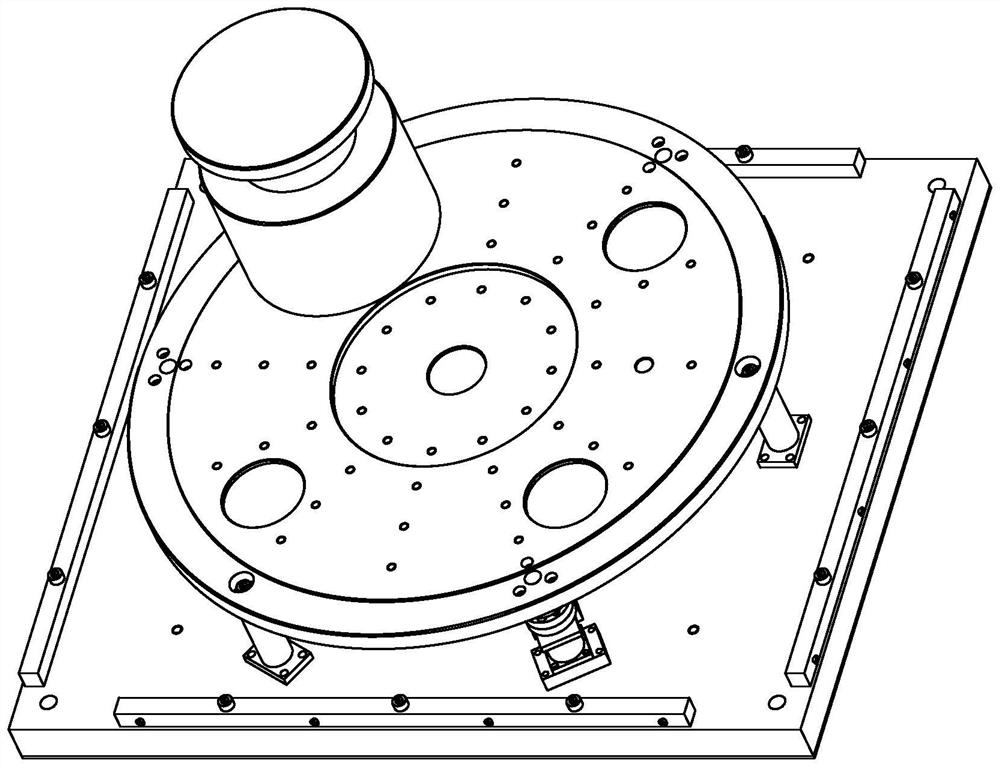

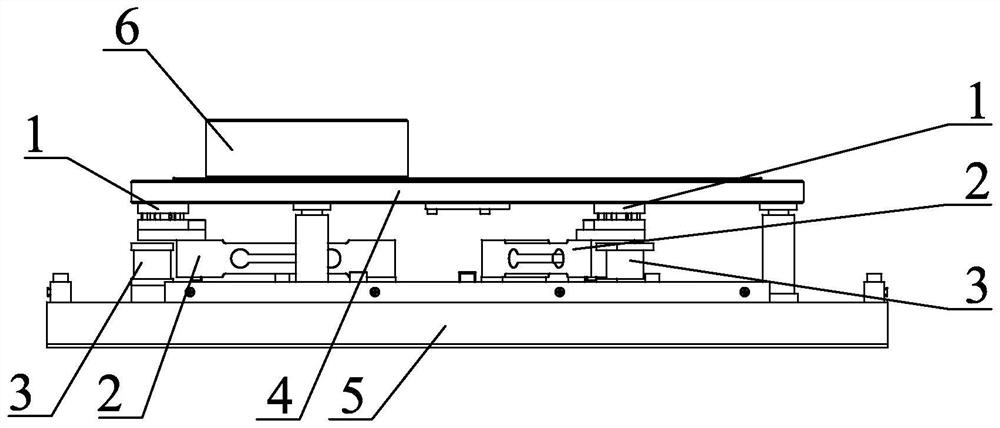

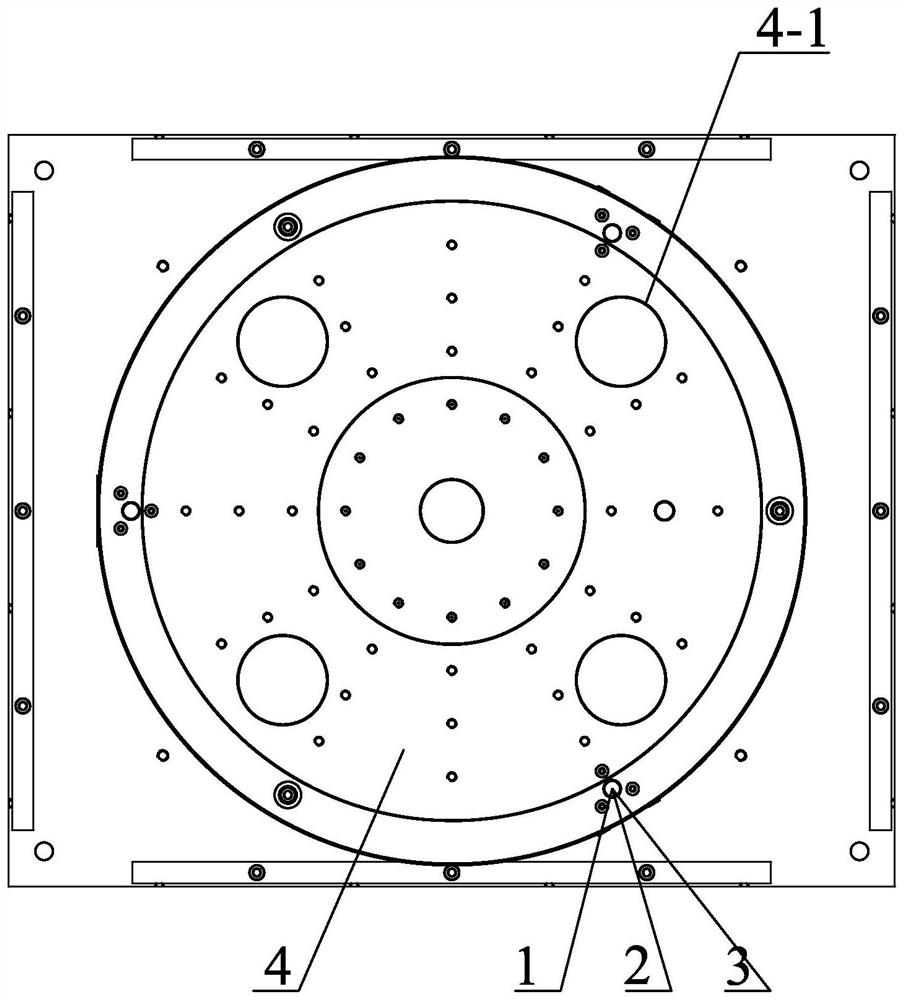

[0036] Specific implementation mode one: combine Figure 1 to Figure 4 Describe this embodiment, a two-dimensional centroid measuring device described in this embodiment includes three floating fulcrums 1 and three sensors 2, a weighing pan 4, a bottom plate 5, and a fixture 6. The bottom plate 5 is arranged horizontally, and the upper part of the bottom plate 5 is along the same circle. Three sensors 2 are evenly distributed in the circumferential direction of the sensor 2, and a floating fulcrum 1 is arranged above the sensor 2. A weighing pan 4 is mounted on the upper ends of the three floating fulcrums 1, and a clamp 6 is arranged on the weighing pan 4.

[0037] The invention proposes a weighing device with a floating fulcrum, a sensor, and a weighing pan as main parts, which can not only weigh the weight of an item, but also measure the two-dimensional centroid distance of the item relative to a reference position. It has the characteristics of compact structure, high pre...

specific Embodiment approach 2

[0047] Specific implementation mode two: combination Figure 1 to Figure 4This embodiment will be described. In this embodiment, an overload protection 3 is provided between the sensor 2 and the upper end surface of the bottom plate 5 . The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0048] Specific implementation mode three: combination Figure 1 to Figure 4 To describe this embodiment, the floating fulcrum 1 , the sensor 2 and the overload protection 3 at the same end of the bottom plate 5 in this embodiment are arranged coaxially. The undisclosed technical features in this embodiment are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com