Single reed leaf feeding and sorting system and method

A sorting system and technology of zongzi, applied in sorting and other directions, can solve the problems of low efficiency, long time, complex structure, etc., and achieve the effect of improving the sorting speed and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

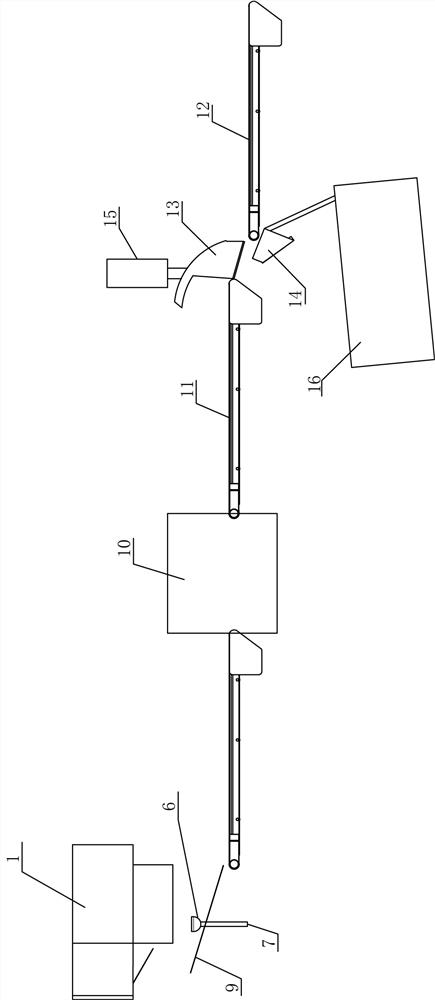

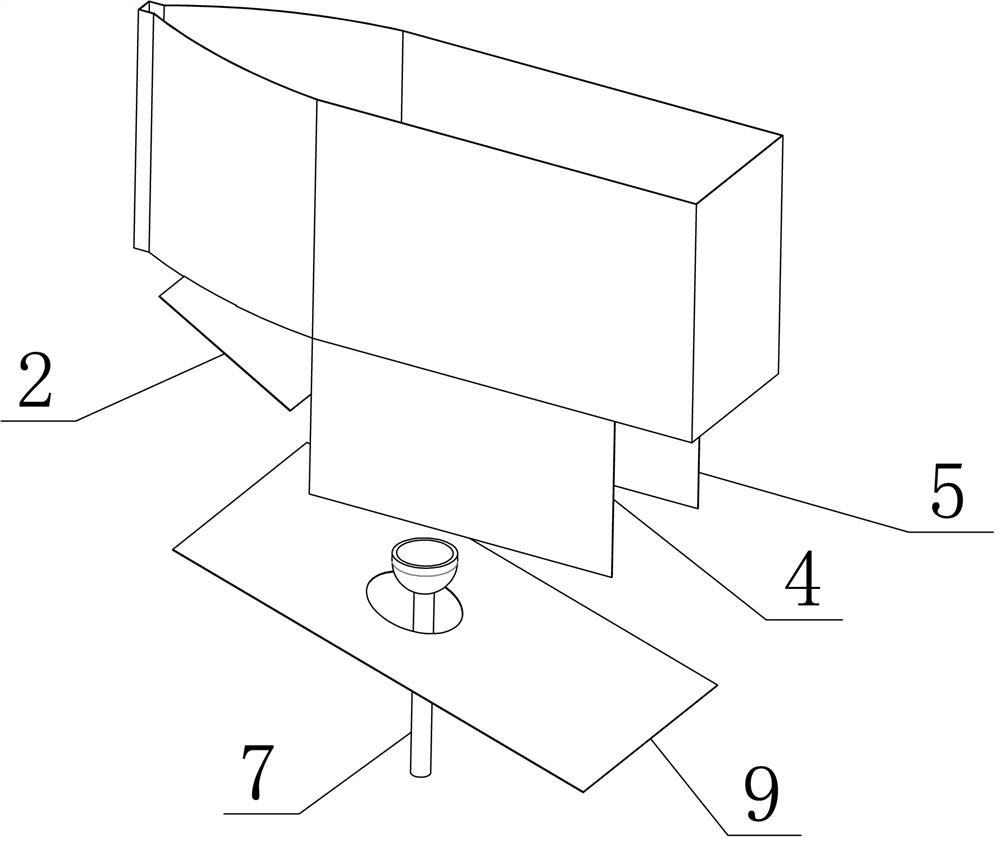

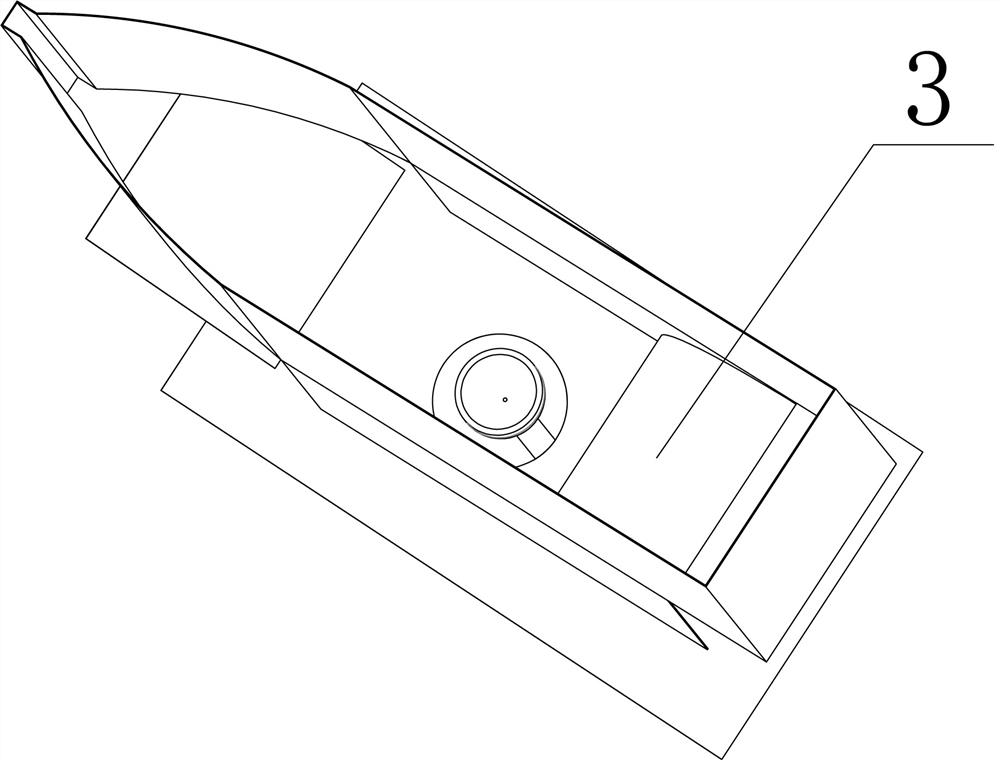

[0042] The preferred solution is as Figure 1 to Figure 4Shown, a kind of single-sheet feeding and sorting system of zong leaves includes a single-sheet feeding device, a size detection device 10 and a single-sheet sorting device, and the single-sheet feeding device includes a storage frame 1, a storage frame 1 The bottom is provided with a first baffle and a second baffle, the first baffle and the second baffle are arranged obliquely and form an opening that gradually narrows from top to bottom, and a vacuum suction cup 6 and a guide baffle are arranged below the opening 9. There is a through hole in the middle of the guide baffle 9, and the vacuum chuck 6 is driven by a driving mechanism, which is used to drive the vacuum chuck 6 to move above the through hole or up and down the through hole; the guide baffle 9 is set obliquely downward , The lower end of guide baffle plate 9 is provided with conveyer, and conveyer is used for conveying zongzi to size detection device and sh...

Embodiment 2

[0067] On the basis of embodiment 1, another kind of structure of leaflet sorting device is as follows:

[0068] Such as Figure 5-6 As shown, the sheet sorting device includes a first conveyor 11 for sorting and a second conveyor 12 for sorting, the first conveyor 11 for sorting is higher than the second conveyor 12 for sorting, and left and right sides are respectively arranged on both sides of the second conveyor 12 for sorting. Material frame 17 and right material frame 18, left material frame 17 and right material frame 18 are respectively provided with left rotation mechanism and right rotation mechanism, and left rotation mechanism is used to drive left material guide groove box 19 to rotate, and right rotation Mechanism is used to drive right feed chute box 20 to rotate; Left feed trough box 19 is used for sorting and is used to guide the zong leaves on the first conveyer 11 to the left material frame 17, and right feed trough box 20 is used for sorting Select the ric...

Embodiment 3

[0071] A method for operating a leaflet feeding and sorting system for zong leaves, comprising the following steps:

[0072]S1: Stack a number of zong leaves into the storage box 1, wherein the tip of the zong leaves faces the side of the shrapnel 2, and the root of the zong leaves faces the side of the guide bending plate 3; under the influence of the weight of the zong leaves, the middle part of the zong leaves faces downward protruding;

[0073] S2: Turn on the vacuum suction cup 6 and the driving mechanism, the driving mechanism drives the vacuum suction cup 6 to move upward, the vacuum suction cup 6 contacts the zong leaves and absorbs the zong leaves;

[0074] S3: The driving mechanism drives the vacuum suction cup 6 to move downward, and the vacuum suction cup 6 absorbs a single piece of zong leaves and grabs the zong leaves to the guide baffle 9;

[0075] S4: the vacuum suction cup 6 stops pumping air, and the single zong leaf slides down to the conveyor along the gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com