Municipal road repairing device for different crack sizes

A road repair and crack technology, applied in the municipal field, can solve the problems of affecting the appearance, inconvenient removal of impurities by adjusting the repair width, shortening the service life of the road surface, etc., to achieve the effect of facilitating automatic cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

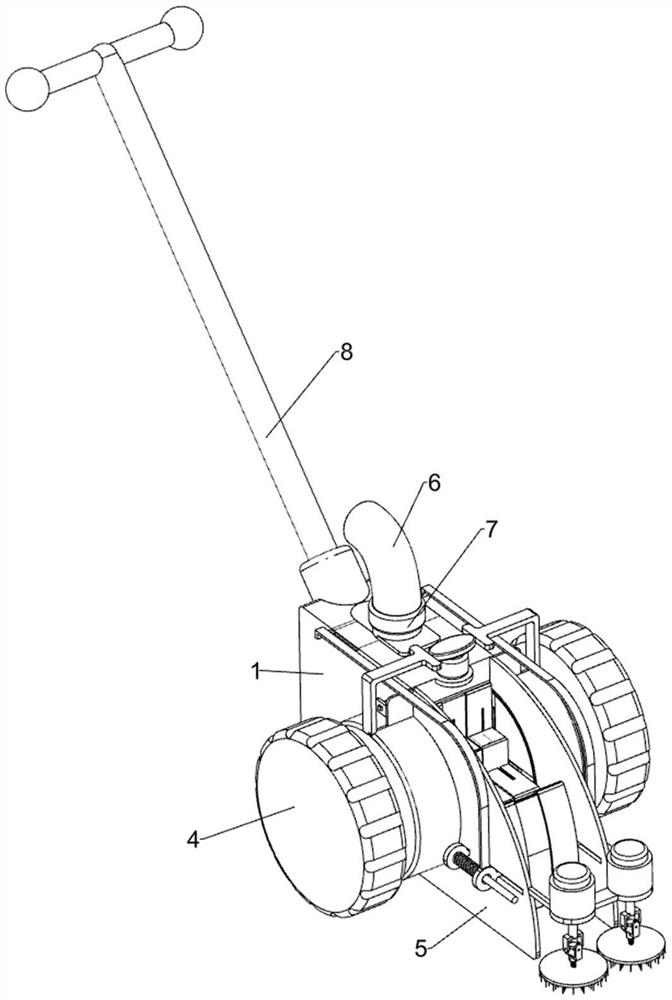

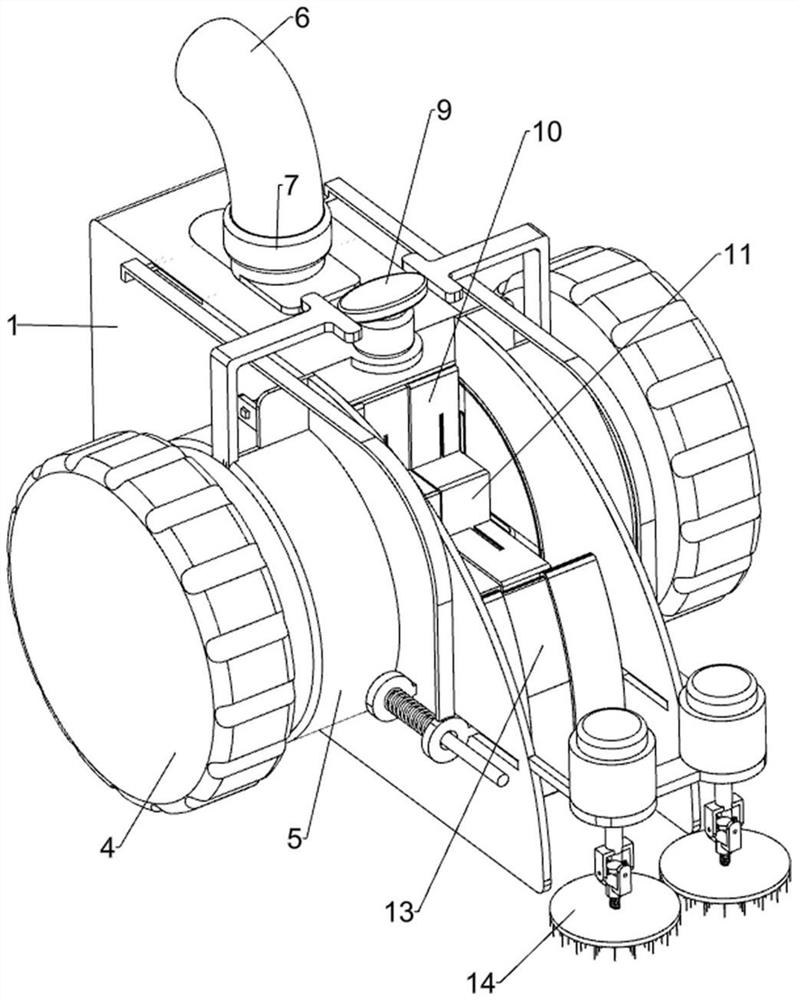

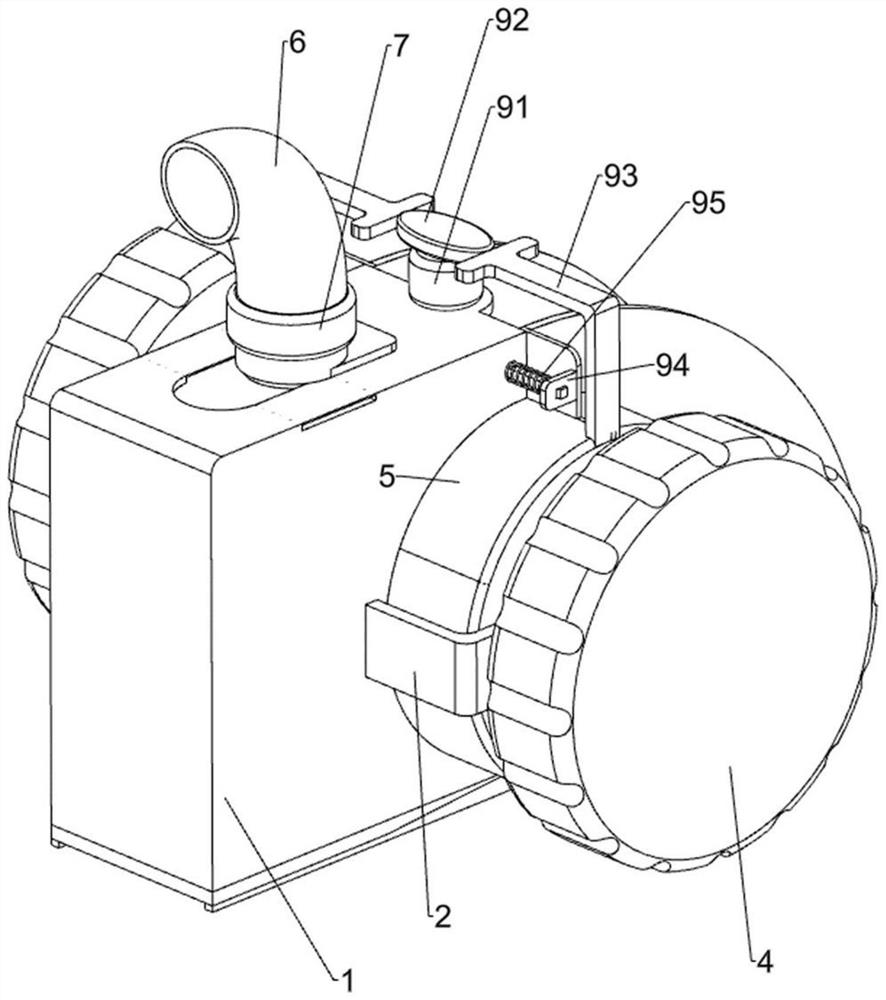

[0035] A municipal road repair device for different crack sizes, such asfigure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown, it includes a storage frame 1, a shaft support 2, a spline shaft 3, a tire 4, a sliding frame 5, a feeding pipe 6, a solenoid valve 7, a hand push frame 8, a spacing adjustment mechanism 9, an asphalt laying mechanism 10, The scraper combination mechanism 11 and the scraper mechanism 12, two shaft brackets 2 are fixedly connected to the storage frame 1, and the shaft brackets 2 are arranged symmetrically, and the shaft brackets 2 are jointly rotated and connected with a spline shaft 3, a spline The shaft 3 is connected with two tires 4 by welding, the tires 4 are arranged symmetrically, and the storage frame 1 is slidably connected with two sliding frames 5, the sliding frames 5 are also arranged symmetrically, and the spline shaft 3 passes through the sliding Frame 5, th...

Embodiment 2

[0043] On the basis of Example 1, such as Figure 11 with Figure 12 Shown, also include a blanking speed control mechanism 13, the blanking speed control mechanism 13 is located on the slide frame 5, the blanking speed control mechanism 13 is used to control the blanking speed according to the depth of the crack, the blanking speed control mechanism 13 Including a first arc-shaped plate 131, a second arc-shaped plate 132, a fixed guide bar 133, a second coil spring 134, a connecting bar 135 and an opening and closing plate 136, the first arc-shaped plate 131 is slidably connected to the inside of the sliding frame 5, A second arc-shaped plate 132 is slidably connected between the first arc-shaped plates 131, and a fixed guide bar 133 is connected to the outside of the sliding frame 5 by welding. The first arc-shaped plate 131 passes through the fixed guide bar 133, and A second helical spring 134 for resetting is connected between the shaped plate 131 and the fixed guide bar...

Embodiment 3

[0046] On the basis of Example 2, such as Figure 13 , Figure 14 with Figure 15As shown, a crack cleaning mechanism 14 is also included. The crack cleaning mechanism 14 is arranged between the two sliding frames 5. The crack cleaning mechanism 14 is used to clean up impurities in the crack. The crack cleaning mechanism 14 includes a second fixed frame 141, The second motor 142, the first universal shaft 143, the universal joint 144, the second universal shaft 145, the torsion spring 146, the brush 147, the third coil spring 148 and the universal ball 149, fixed welding between the sliding frame 5 There is a second fixed frame 141, and the second fixed frame 141 is located in front of the sliding frame 5, and the second fixed frame 141 is connected with two second motors 142 by bolts, and the output shaft of the second motor 142 is fixedly connected with the first universal Shaft 143, the first cardan shaft 143 passes through the second fixed mount 141, the second fixed mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com