Metal hose connector structure

A joint structure, metal hose technology, applied in the direction of hose connection device, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problem that the connecting pipe is easy to separate from the hose, the stability is poor, and the connecting pipe is difficult to connect. It can ensure the convenience of installation, reduce maintenance trouble, and prevent separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

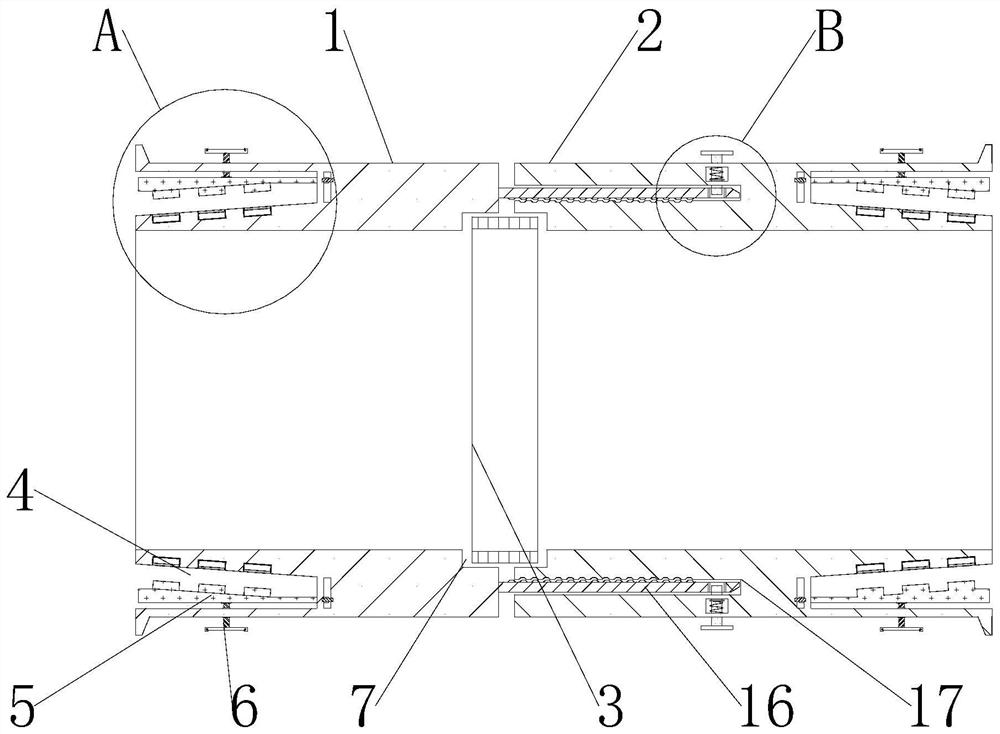

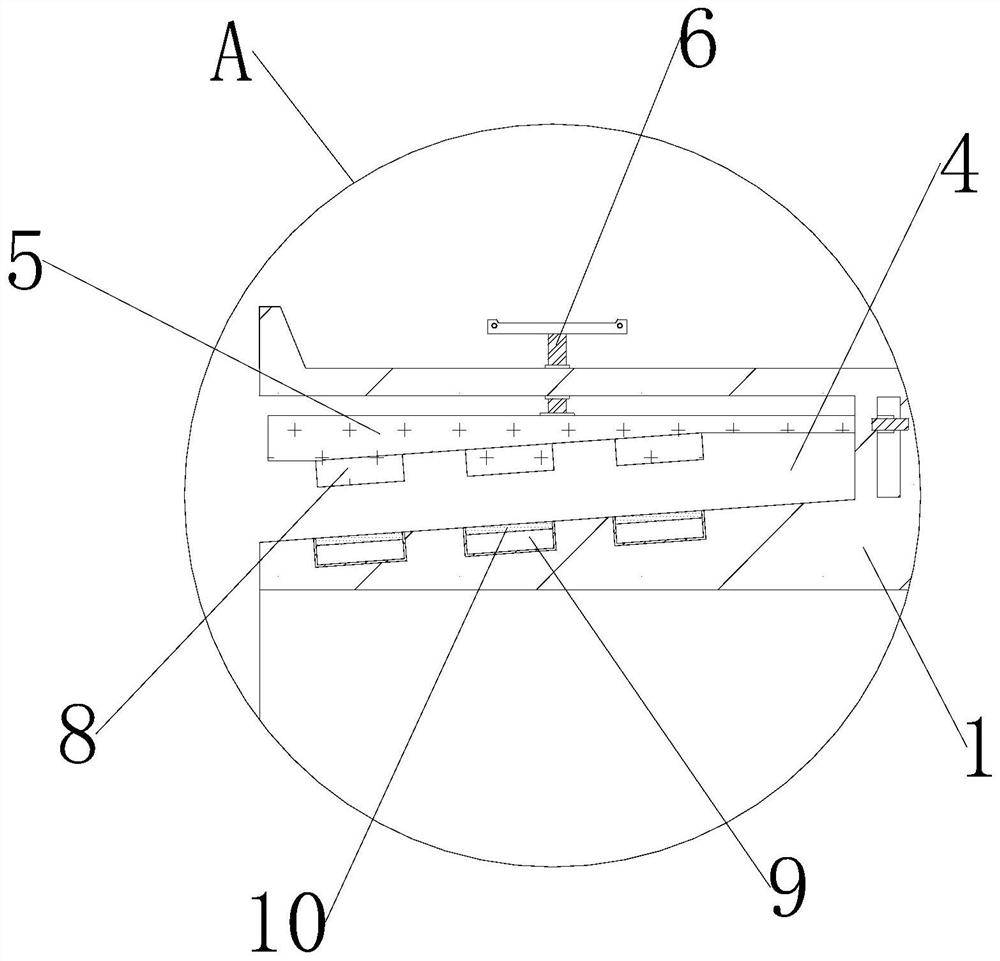

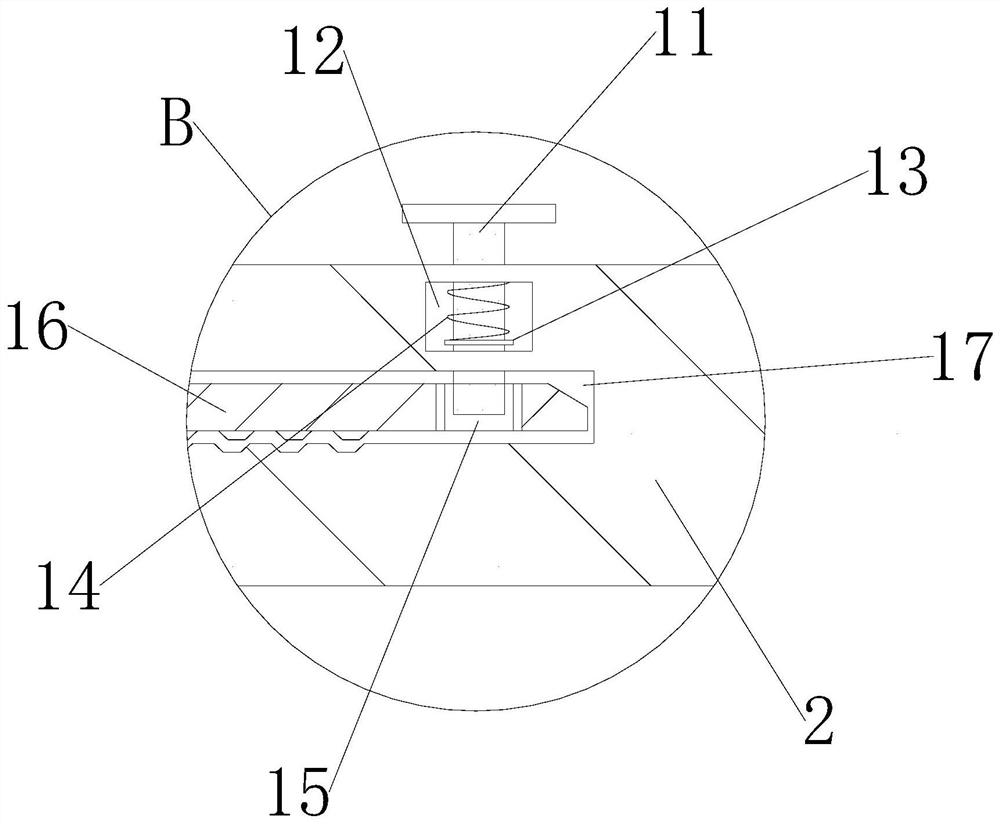

[0021] see Figure 1 to Figure 5 :

[0022] A metal hose joint structure, comprising a left connecting pipe 1 and a right connecting pipe 2, the right connecting pipe 2 is located at the right end of the left connecting pipe 1:

[0023] The outside of the left connecting pipe 1 and the right connecting pipe 2 are provided with an annular connecting groove 4, and the upper and lower ends of the annular connecting groove 4 are slidably connected with splints 5, and the left connecting pipe 1 and the right connecting pipe are connected The upper and lower ends of the tube 2 and the outer periphery of the annular connection groove 4 are threadedly connected with locking rods 6, and the inner side of each splint 5 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com