Cutting tool

A cutting tool and tool body technology, which is applied in the field of tool design and manufacturing, can solve problems such as force deformation of the positioning surface, and achieve the effect of stably clamping the blade and reducing inclination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

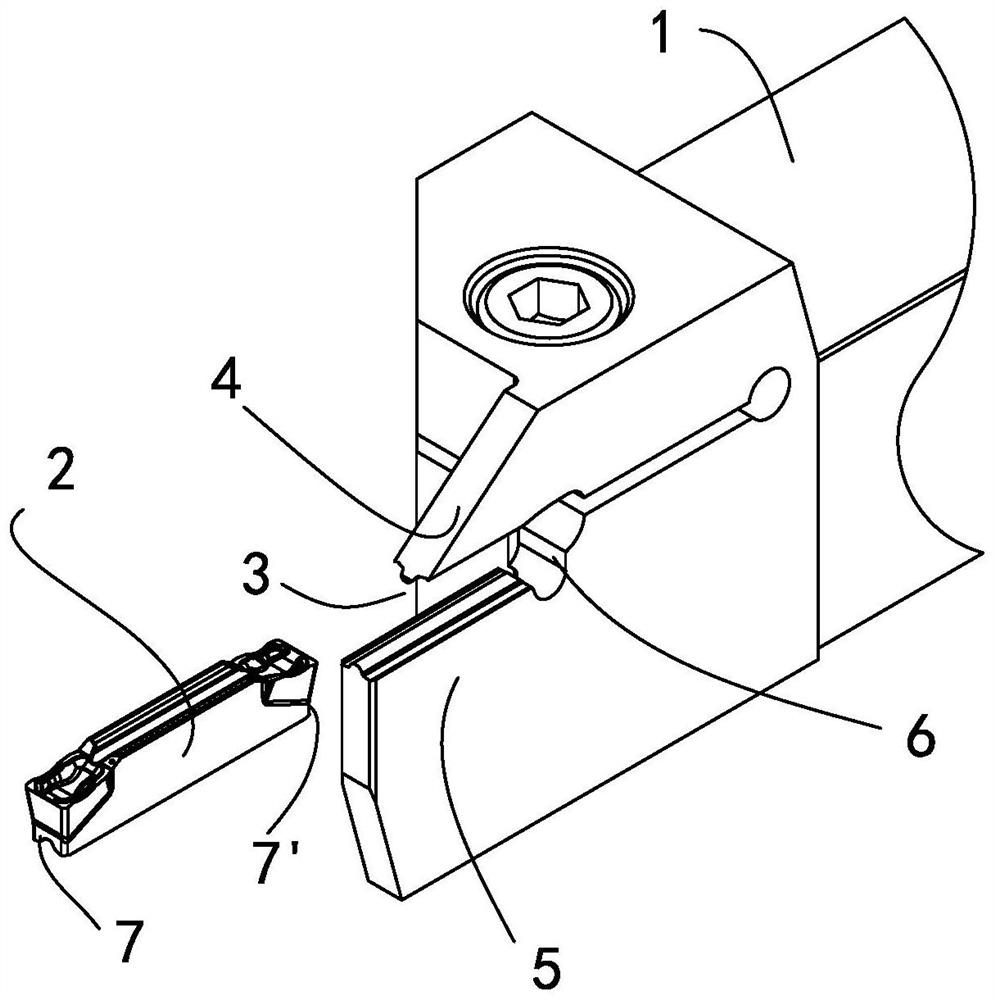

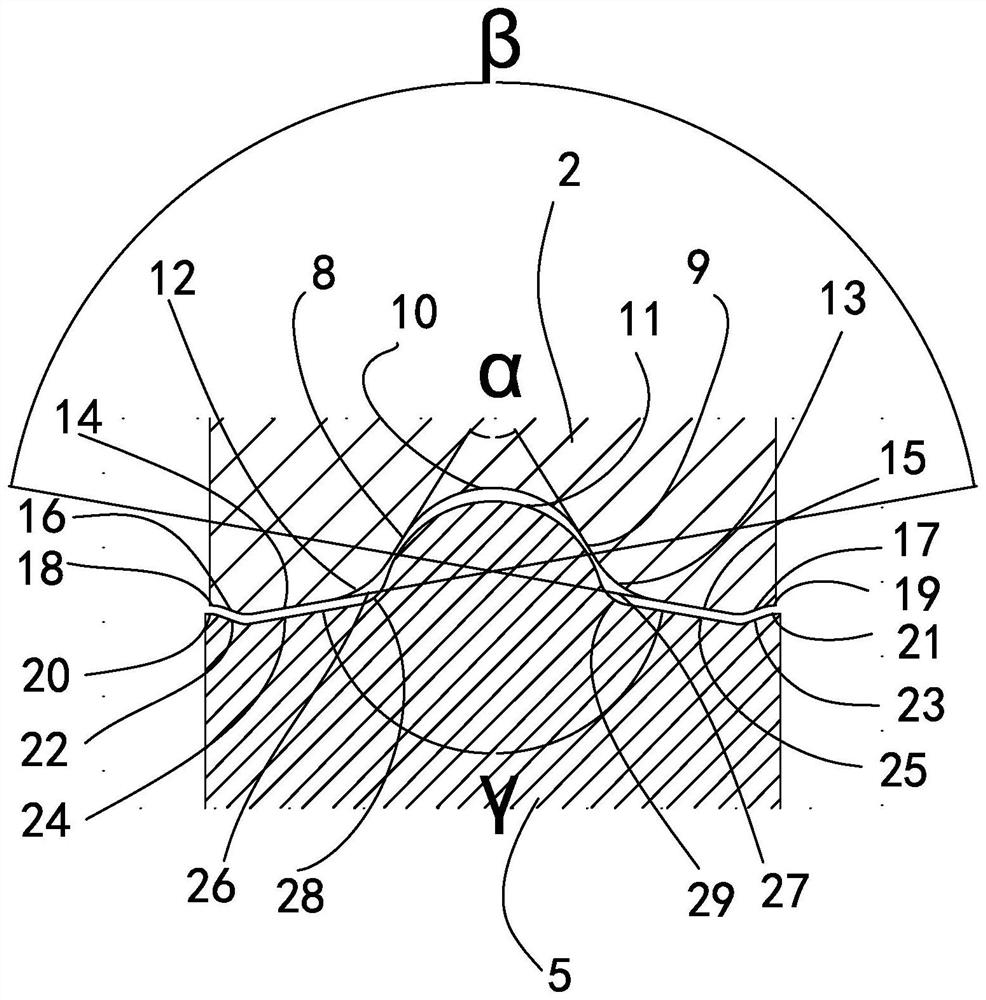

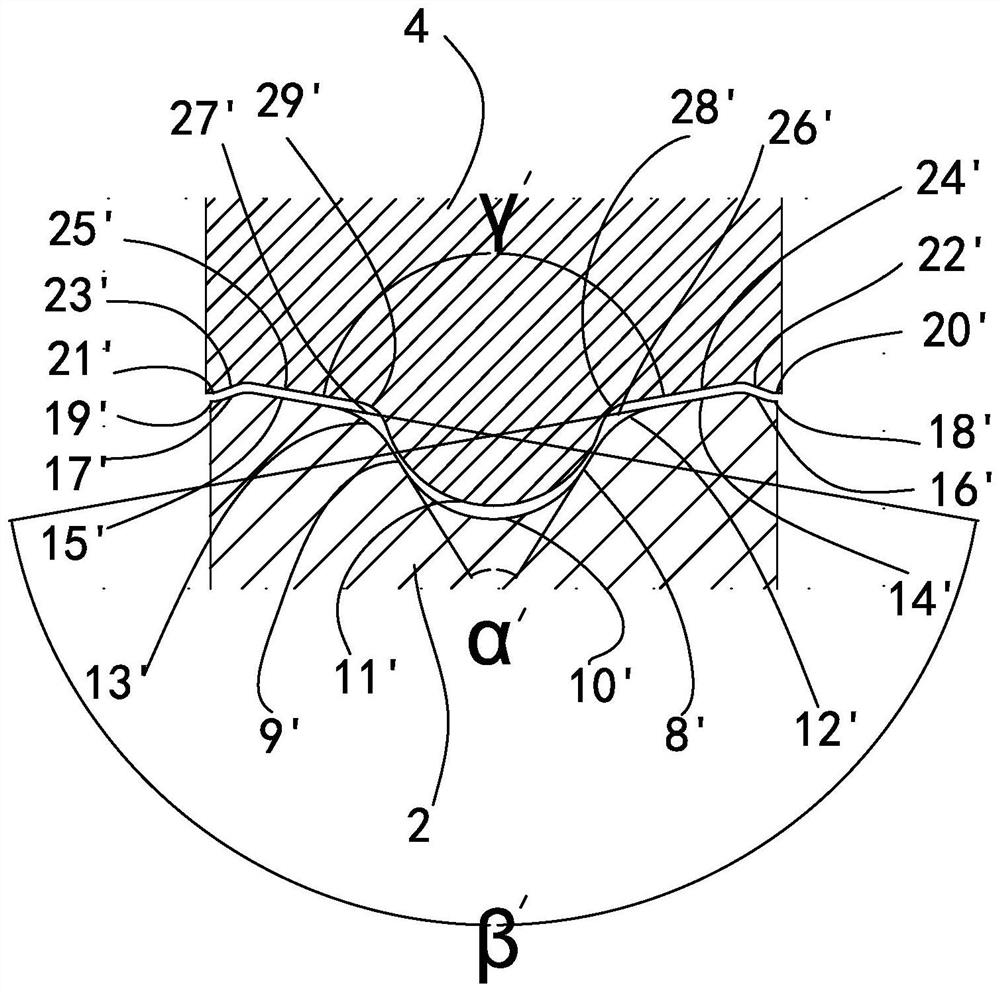

[0030] see Figure 1 to Figure 8 As shown, a cutting tool of the present invention includes a cutter body 1 made of a first material and a blade 2 made of a second material that is harder than the first material; wherein, the cutter body is made The first material of 1 can be steel, including various alloy steels, spring steel, etc.; the second material of blade 2 can be hard alloy or cermet.

[0031] see figure 1As shown, the front end of the cutter body 1 is provided with a groove 3 for clamping the blade 2, the groove 3 is composed of an upper elastic clamping arm 4, a lower rigid clamping part 5 and a rear positioning surface 6, and Through mechanical clamping, the cutter body 1 clamps the blade 2 from the up and down direction; the blade 2 is installed in the groove 3 of the cutter body 1, and the bottom of the blade 2 is supported by the lower rigid clamping part 5 of the cutter body 1 , the top of the blade 2 is pressed and clamped by the upper elastic clamping arm 4;...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap