Anhydrous ground edge-closing reinforcing structure

A technology for strengthening structures and grounds, applied to floors, building structures, local raised floors, etc., can solve problems such as unstable structures near walls, and achieve the effect of convenient disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

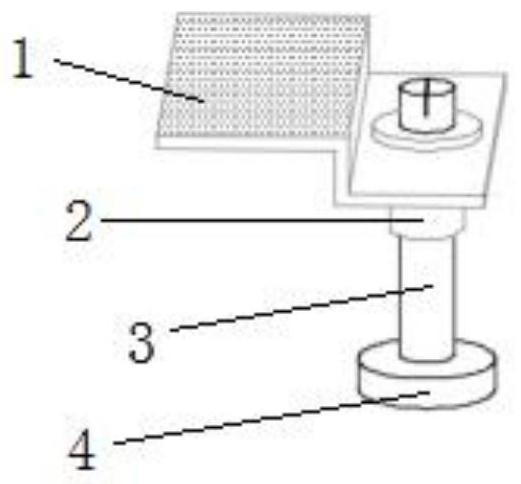

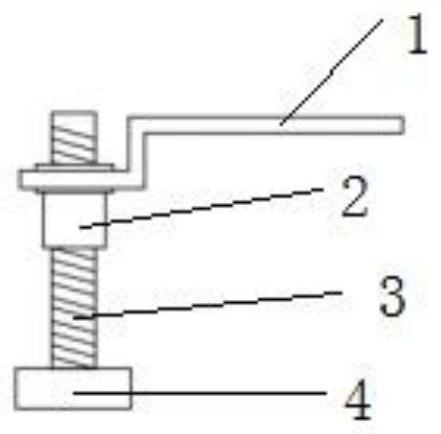

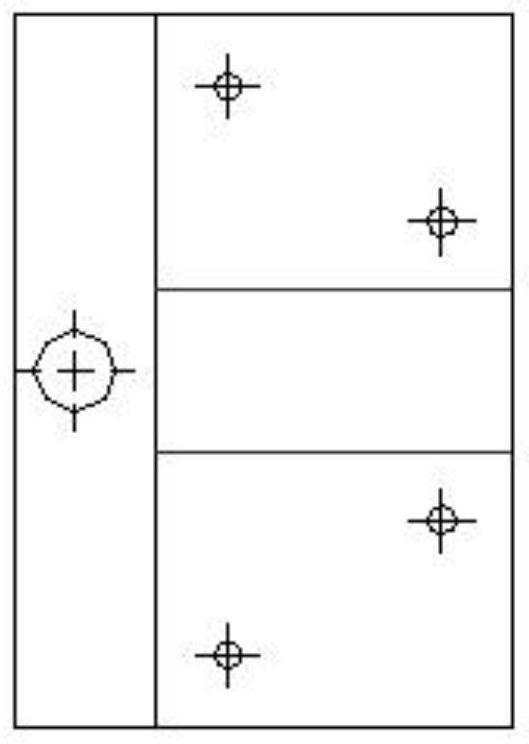

[0029] In order to further illustrate the technical means and effects adopted by the present invention to achieve the intended purpose, the specific implementation, structural features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0030] Refer to attached Figure 7 , the present embodiment provides an anhydrous ground edge reinforcement structure, the anhydrous ground edge reinforcement structure includes a folding clip 5 and an edge adjustment leg. The upper side of the folding clip 5 is provided with a fixing hole for punching steel nails, and the folding clip 5 fixes the overhead base plate by the steel nails. The folding clip and the edge adjustment feet tightly clamp the overhead base board, and the other side is only attached to the wall to prevent the overhead module from moving laterally.

[0031] The lower side of the folding clip 5 is provided with a round hole, and the round hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com