Stainless steel plate conveying upper elastic clamping piece structure

A technology of stainless steel plates and clips, applied in the direction of manufacturing tools, hand-held tools, etc., to reduce the difficulty of installation and maintenance and facilitate adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

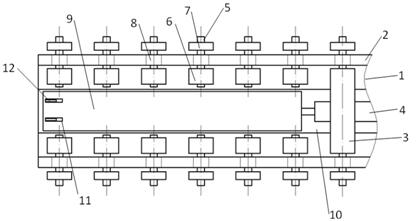

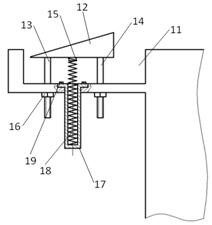

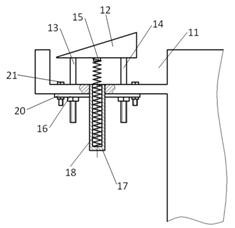

[0032] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

[0033] Such as Figure 1~4 As shown in the figure, a stainless steel plate transmission upper bullet clip structure includes a fixed frame bottom plate 1, and two fixed frame side plates 2 are arranged on the fixed frame bottom plate 1, and a fixed frame side plate 2 is arranged between the two fixed frame side plates. There are conveying rollers 3, a lateral rotation shaft 5 is arranged in the side plate 2 of a single fixed frame, a supporting small roller 6 is arranged on the lateral rotation shaft 5, and a sliding material receiving block 9 is arranged on the bottom plate 1 of the fixed frame, so that An assembly groove 11 is formed in the material receiving block 9 , and an elastically lifting limit block 12 is arranged in the assembly groove 11 , and the limit block 12 is driven by a spring 18 in a spring sleeve 17 .

[0034] A guide assembly for lifting gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com