Automatic welding device for dense lead-acid storage battery cover plates

A lead-acid battery, automatic welding technology, applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low efficiency, affecting the production of the previous process, increasing labor costs, etc., to achieve a high degree of automation and process continuity Stable, less difficult to install and maintain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

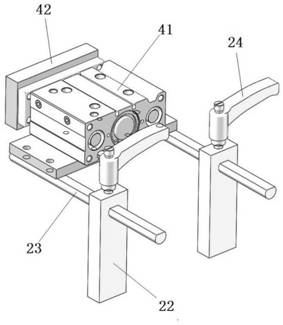

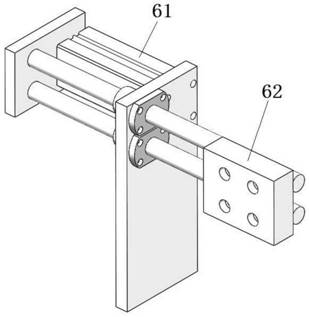

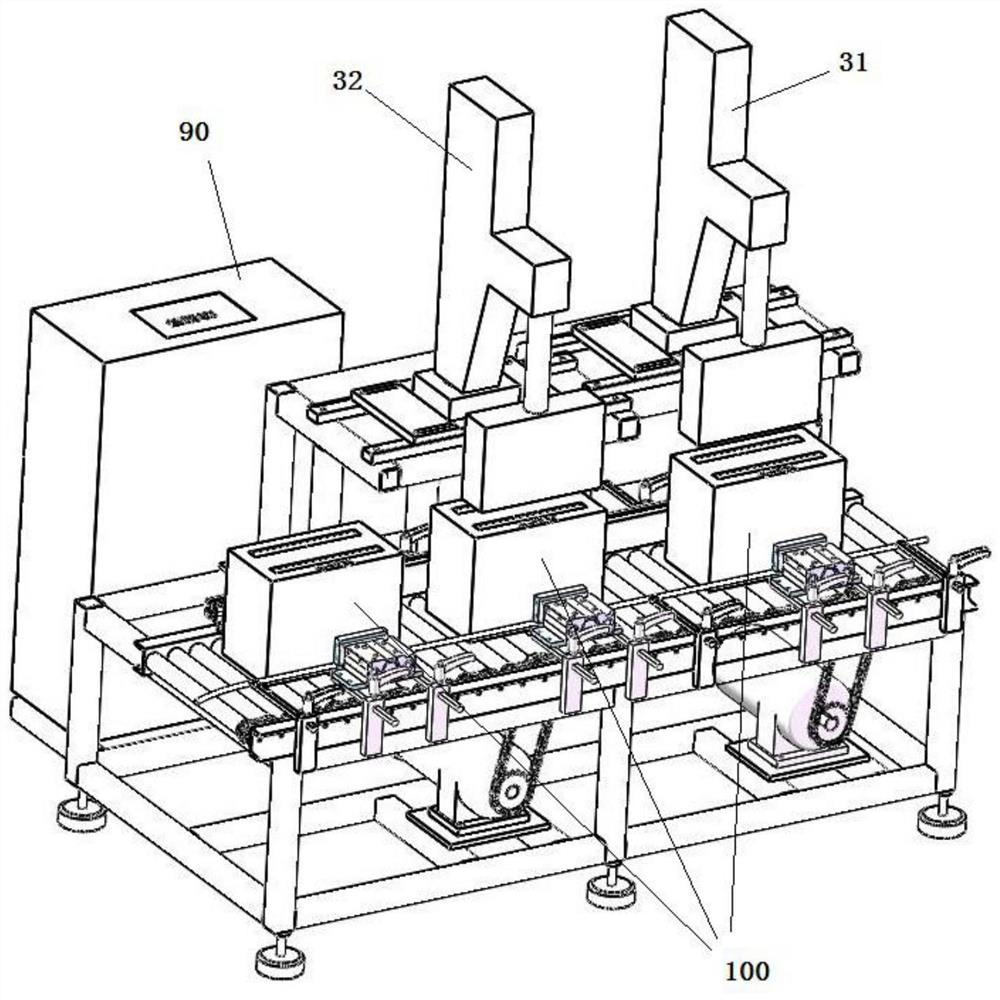

[0021] next combined with Figure 1-6 A specific embodiment of the present invention is described in detail.

[0022] An automatic welding device for cover sheets of dense lead-acid batteries, refer to the attached Figure 1-3 , including a main body bearing structure frame 10, a drum 11 is arranged on the top of the frame 10, a gear 111 is arranged on one side of the drum 11, the gear is connected with a motor fixed on the fuselage 10, and the drum 11 rotates under the drive of the motor, The dense lead-acid battery to be welded is placed on the drum 11 and advances under the friction between it and the drum 11 .

[0023] In this embodiment, in order to ensure the stability of the transmission, the gear 111 adopts a double-row gear, and the fuselage 10 is provided with two motors, the first motor 12 and the second motor 13, refer to the attached figure 2 , the two groups of rollers 11 in the rollers 11 are respectively connected to the output shafts of the first motor 12 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com