Test device for simulating high temperature in tunnel fire

A test device and tunnel technology, applied in the direction of chemical analysis using combustion, can solve the problems of lining damage inside the tunnel, difficulty in escaping people, affecting the strength and service life of the tunnel lining, and achieve high safety performance, injury prevention, increase The effect of authenticity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

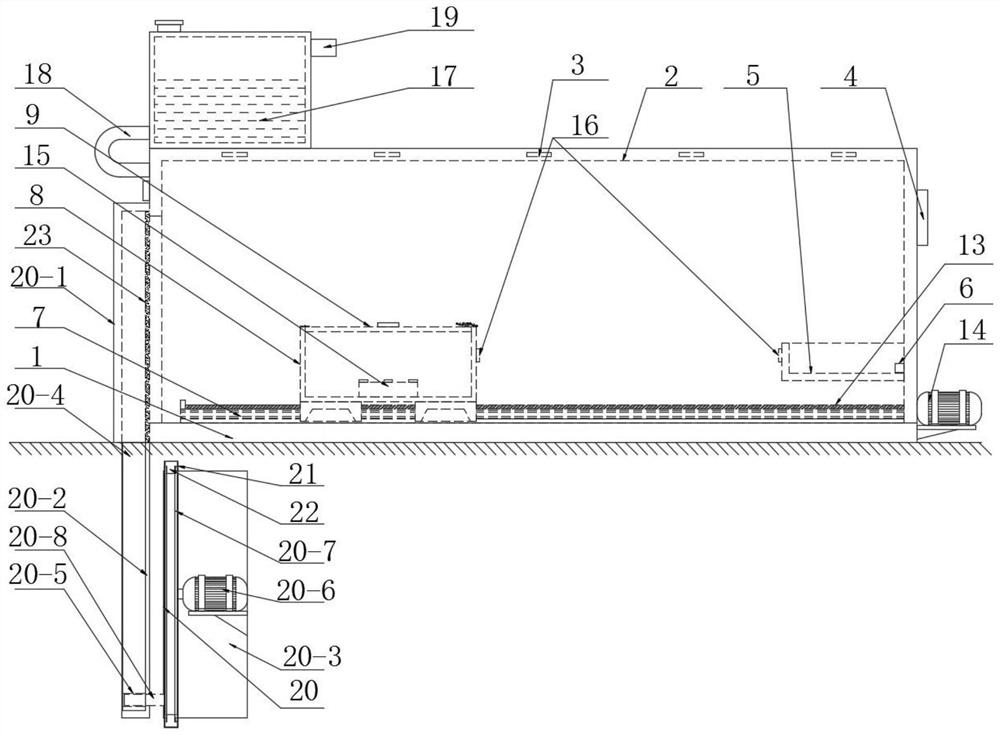

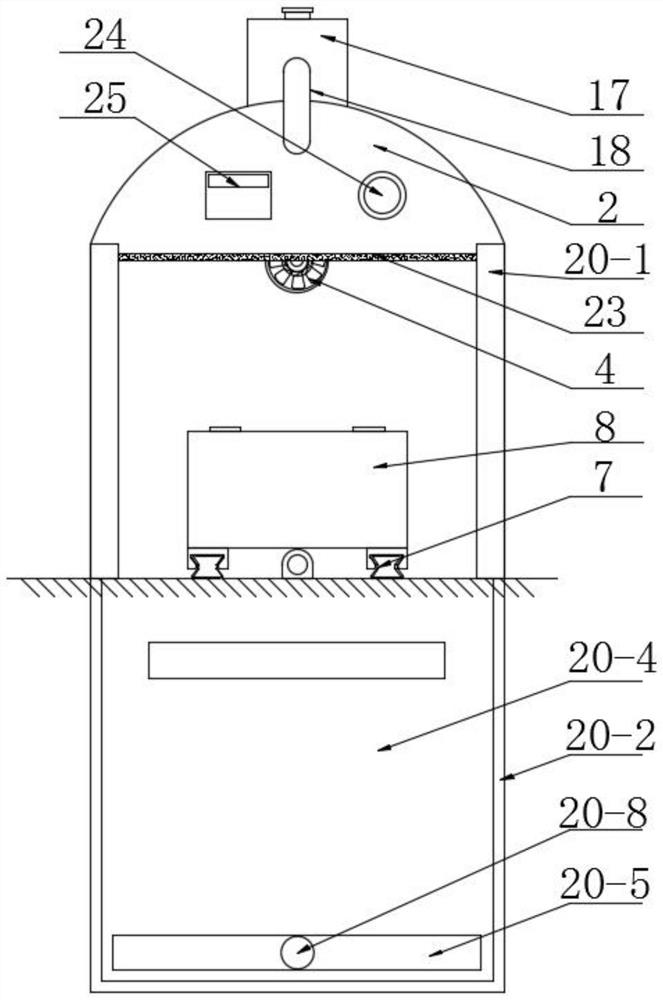

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

[0044] see as Figure 1-Figure 4 As shown, the technical solution adopted in this specific embodiment is: it comprises a base plate 1 and a simulated tunnel 2, the upper side of the base plate 1 is fixedly provided with a simulated tunnel 2, and the left side wall of the simulated tunnel 2 is provided in an opening shape, and the base plate 1 and Simulated tunnel 2 is all prefabricated concrete structures;

[0045] It also contains:

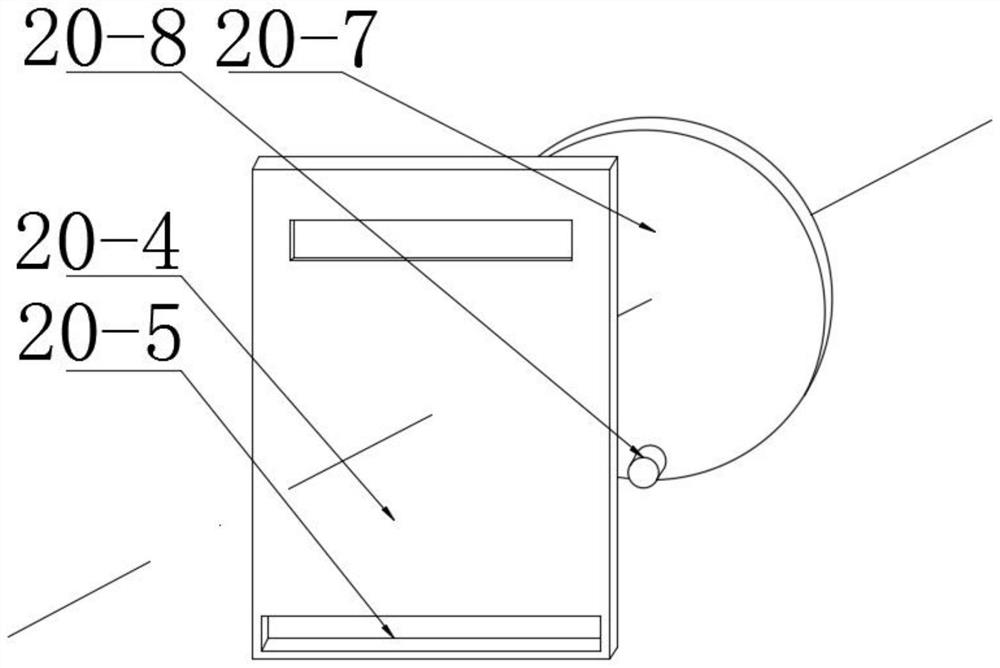

[0046] An explosion-proof door assembly 20, the explosion-proof door assembly 20 is arranged below the ground on the left side of the bottom plate 1;

[0047] Temperature sensor 3, described temperature sensor 3 is several, and is fixedly arranged in the top surface interior of simulation tunnel 2 respectively by bolt equidistant; Described temperature sensor 3 is all connected with external power supply;

[0048] An axial flow fan 4, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com