Preparation method of automobile engine balancer shell

A technology of automobile engine and balancer, which is applied in the field of die casting technology, can solve the problems of accelerating the aging of mold core and cavity, and achieve the effect of improving the qualification rate and increasing the injection force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

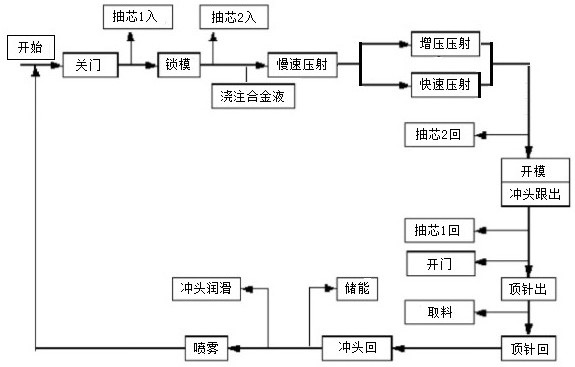

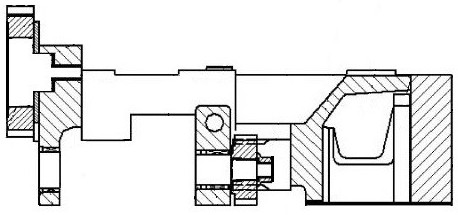

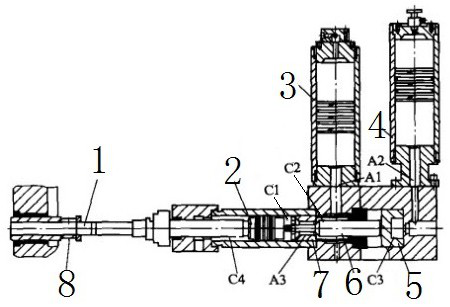

[0022] Attached below Figure 1-3 To further describe the present invention, a method for preparing an automobile engine balancer housing, the material of the automobile engine balancer housing is YZAlSi 9 Cu 3 Aluminum alloy, YZAlSi 9 Cu 3 The aluminum alloy is die-cast in a cold chamber die-casting machine. The cold chamber die-casting machine includes an injection punch 1, a fast injection accumulator 3 and a booster accumulator 4. After the slow injection, the fast injection and Pressurized injection, the rapid injection accumulator 3 and the pressurized accumulator 4 of the cold chamber die-casting machine pressurize the injection punch 1 at the same time until YZAlSi 9 Cu 3 The aluminum alloy liquid fills the mold cavity.

[0023] YZAlSi 9 Cu 3 The die-casting process of aluminum alloy in the cold chamber die-casting machine is controlled by a PLC controller (the prior art), and the fast-injection accumulator 3 and the pressurized accumulator 4 are respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com