Intelligent screw mounting equipment and method for industrial distribution box

A technology for industrial power distribution and installation equipment, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as single function, dirty nut, affecting production speed, etc., achieve flexible and adjustable precision, and improve qualification standards , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

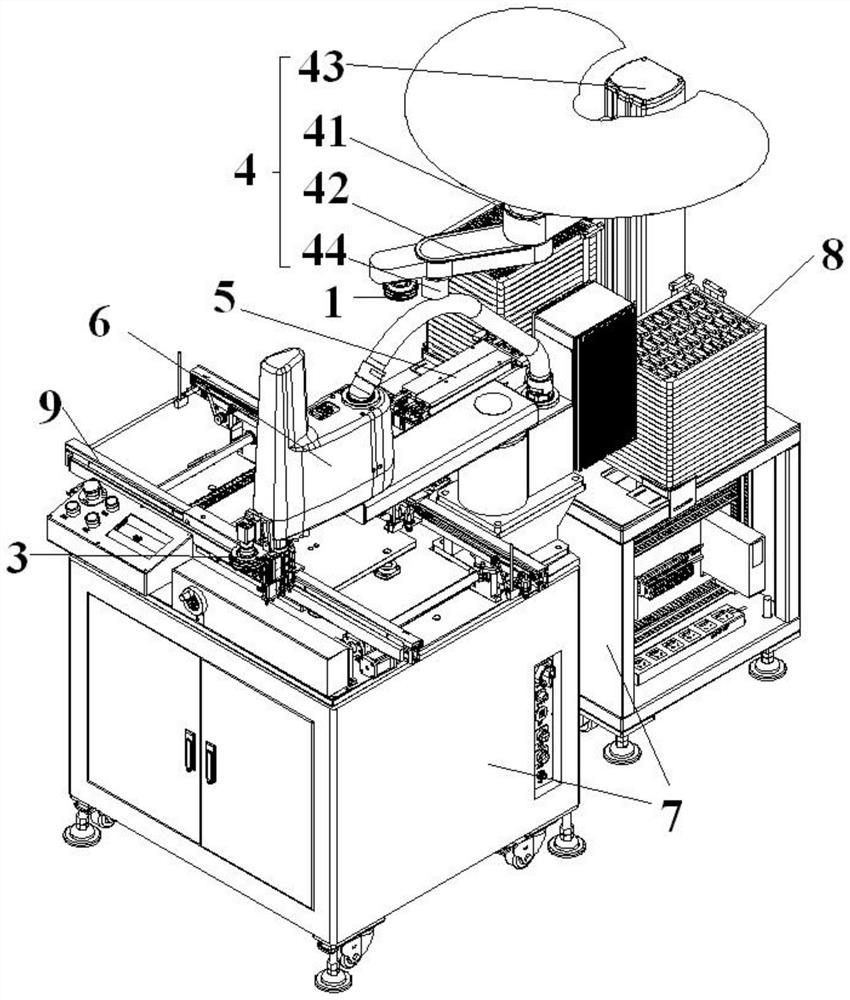

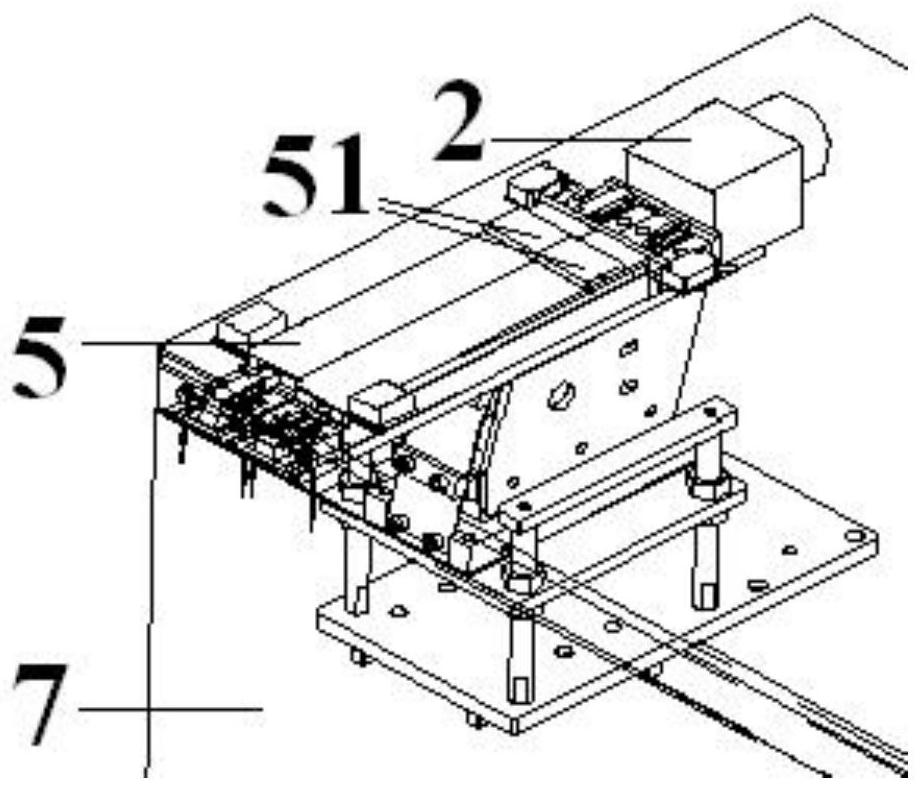

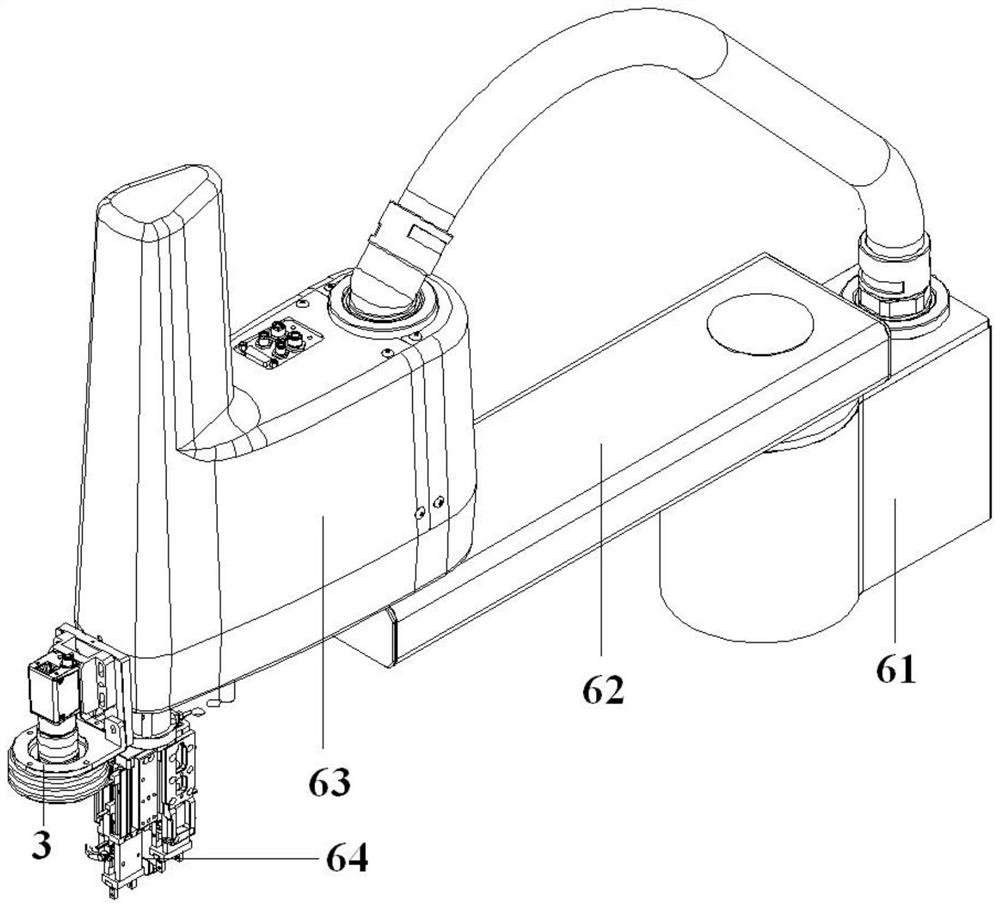

[0047] refer to figure 1 As shown, the present invention provides a screw intelligent installation device for industrial distribution boxes, including a central control module, a material retrieving module, a transmission module and an assembly module; the central control module is electrically connected to the retrieving module, the transmission module and the installation module respectively , used to control the work of each module; the reclaiming module includes a reclaiming manipulator 4 and a first camera 1 installed on the reclaiming manipulator 4, and the transmission module includes a screw track 5 and a second camera 2 installed at the end of the screw track 5 The assembly mo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap