Intelligent air pollution monitoring device and system

A technology for intelligent monitoring and air pollution, applied in measurement devices, air quality improvement, instruments, etc., can solve the problems of scattered staff, inability of staff to take timely measures, and great potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

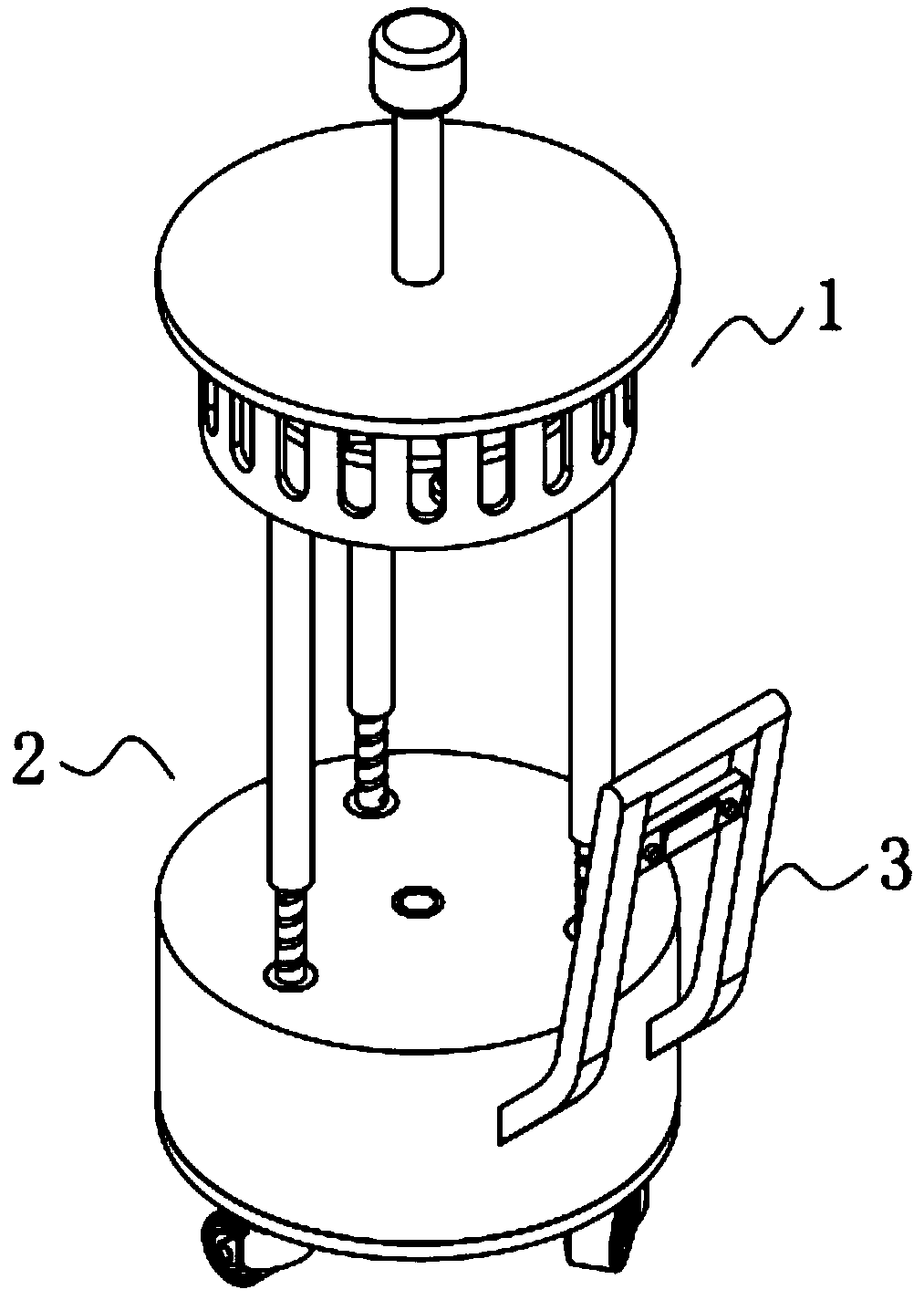

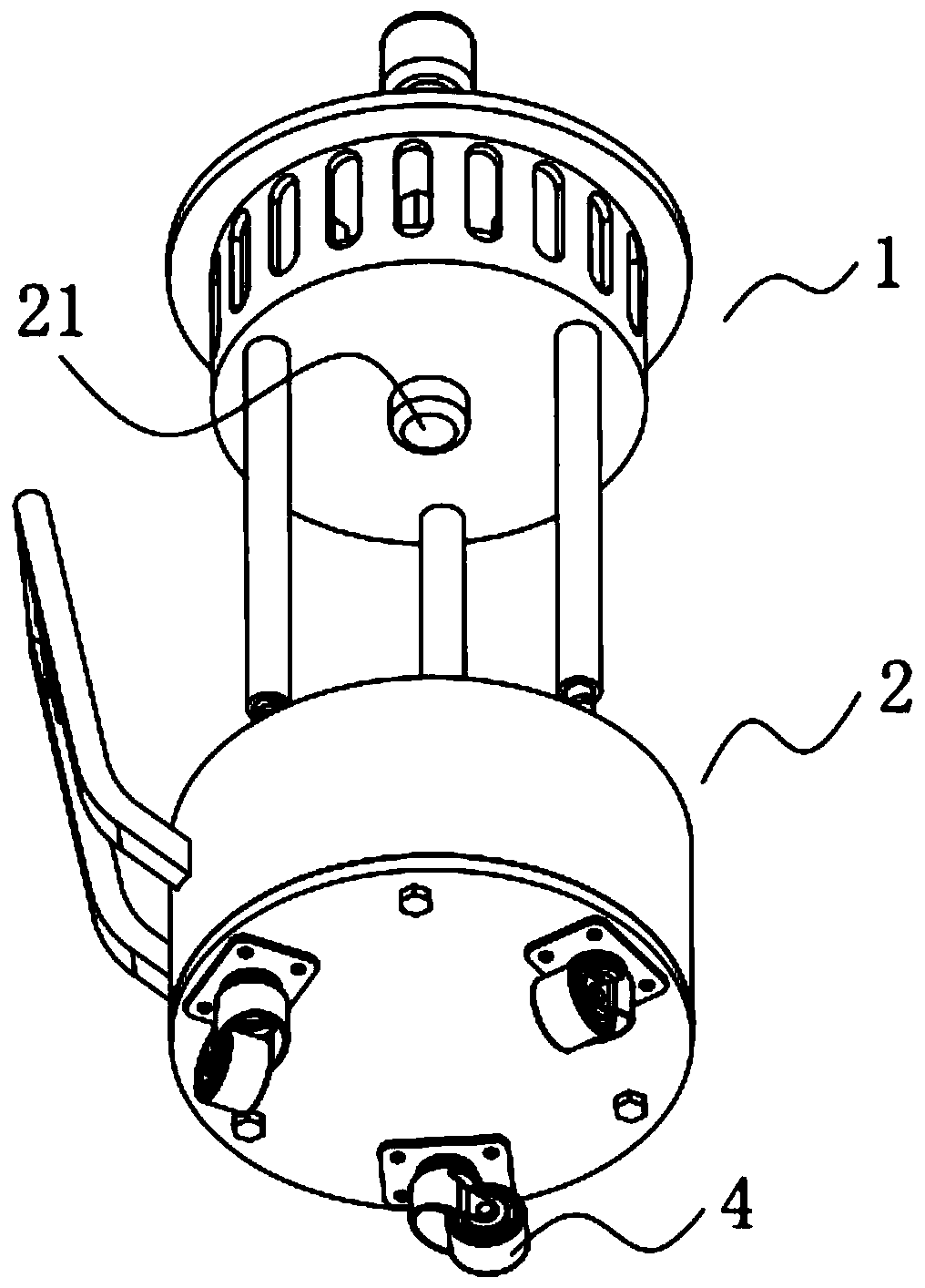

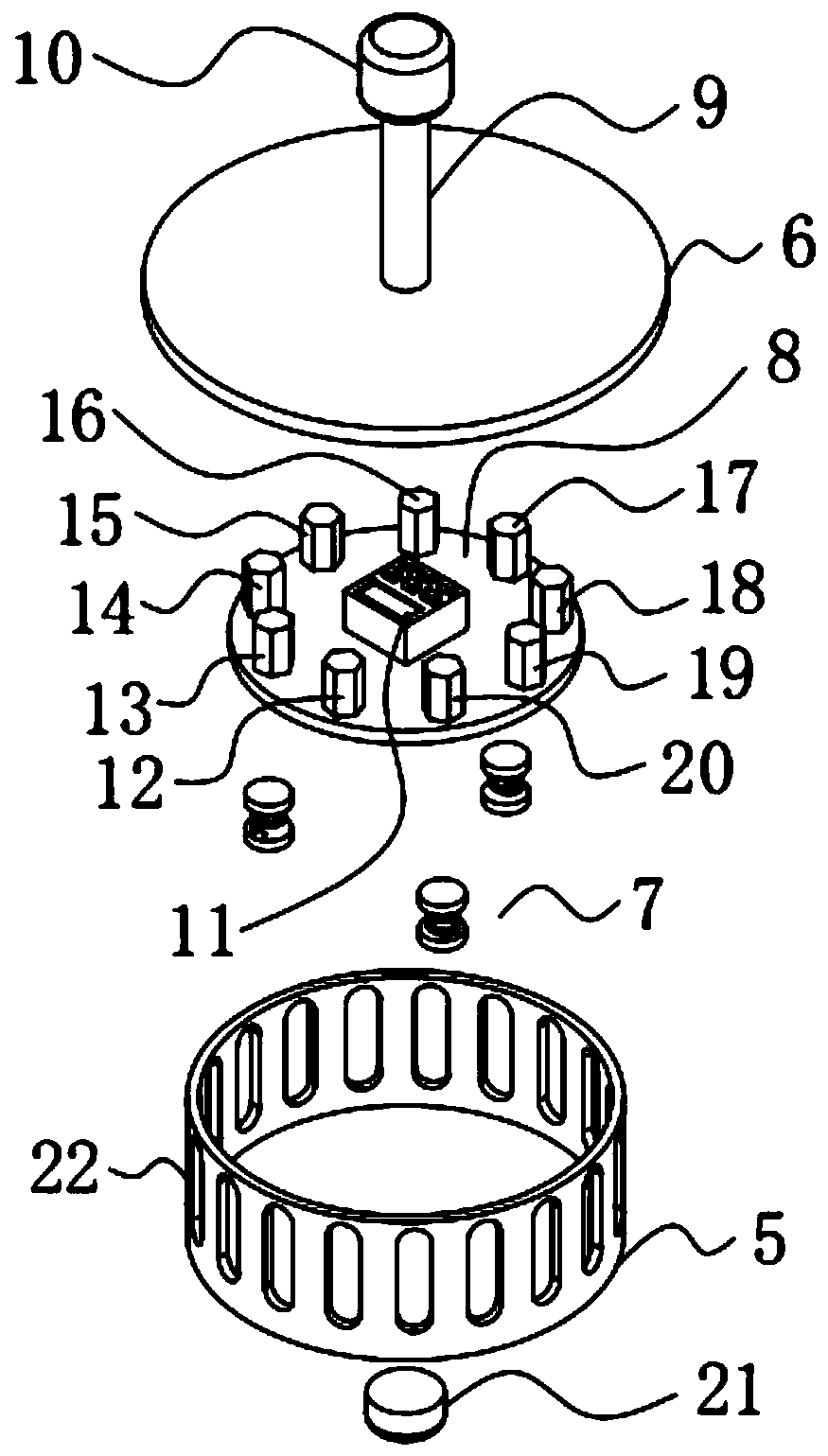

[0056] An air pollution intelligent monitoring device, such as figure 1 and 3 As shown, it includes a monitoring part 1, and the monitoring part 1 includes a cylindrical housing 5, an upper cover 6, a pole 9, an indicator light 10, a mounting plate 8, an elastic component 7, a controller 11, a PM2.5 sensor 12, PM10 sensor 13, carbon dioxide sensor 14, carbon monoxide sensor 15, formaldehyde sensor 16, temperature sensor 17, humidity sensor 18, TVOC sensor 19 and oxygen sensor 20, a number of through holes 22 are evenly opened on the side wall of the cylindrical housing 5 , the mounting plate 8 is fixedly mounted on the inner bottom of the cylindrical housing 5 through the elastic assembly 7, the controller 11 is fixedly mounted on the upper center of the mounting plate 8, and the PM2.5 Sensor 12, the PM10 sensor 13, the carbon dioxide sensor 14, the carbon monoxide sensor 15, the formaldehyde sensor 16, the temperature sensor 17, the humidity sensor 18, the TVOC sensor 19 and...

Embodiment 2

[0079] The difference from Example 1 is that the surface of the cylindrical casing 5 is also provided with a protective layer, and the protective layer is prepared by the following method:

[0080] Take the following raw materials and weigh them by weight: 16 parts of epoxy resin, 7 parts of calcium carbonate powder, 14 parts of melamine resin, 13 parts of phenolic resin, 8 parts of glass powder, 15 parts of polytetrafluoroethylene, 8 parts of talcum powder, alcohol ester 3 parts of twelve, 2 parts of triethanolamine, 2 parts of emulsified silicone oil and 30 parts of ethanol;

[0081] S1. Add the weighed alcohol ester dodecane, triethanolamine, emulsified silicone oil and ethanol into the mixer and stir for 22min at a stirring speed of 500r / min to prepare a mixed solution;

[0082] S2. Add epoxy resin, calcium carbonate powder, melamine resin, phenolic resin, glass powder, polytetrafluoroethylene and talcum powder into a pulverizer and pulverize until the particle diameter of...

Embodiment 3

[0088] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0089] Take the following raw materials and weigh them by weight: 20 parts of epoxy resin, 9 parts of calcium carbonate powder, 16 parts of melamine resin, 14 parts of phenolic resin, 9 parts of glass powder, 18 parts of polytetrafluoroethylene, 10 parts of talcum powder, alcohol ester Twelve 4 parts, triethanolamine 3 parts, emulsified silicone oil 3 parts and ethanol 35 parts;

[0090] S1. Add the weighed alcohol ester dodecane, triethanolamine, emulsified silicone oil and ethanol into the mixer and stir for 25min at a stirring speed of 600r / min to prepare a mixed solution;

[0091] S2, adding epoxy resin, calcium carbonate powder, melamine resin, phenolic resin, glass powder, polytetrafluoroethylene and talcum powder into a pulverizer and pulverizing until the particle diameter of the material is not greater than 200nm to obtain a mixed powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com