Method for improving near-infrared reflectivity of yellow pigment

A yellow pigment and near-infrared technology, applied in chemical instruments and methods, preparation/processing of rare earth metal compounds, inorganic chemistry, etc., can solve the problems of large differences and little reference value of preparation methods, etc., and achieve good heat insulation performance , Improve the effect of near-infrared reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

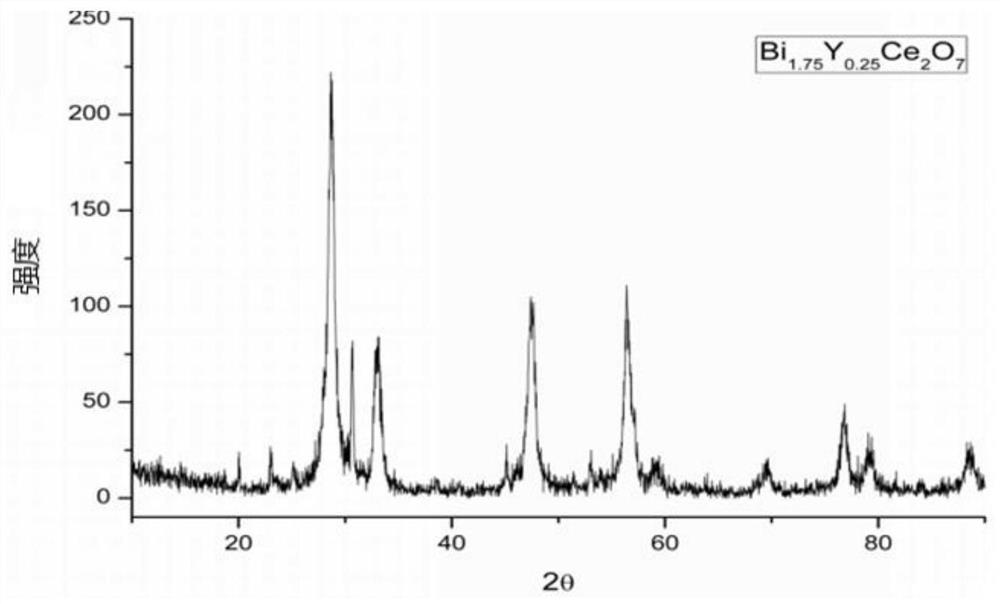

[0053] Prepare an aqueous solution of cerium chloride with a concentration of 1 mol / L. According to the yellow pigment Bi 1.75 Y 0.25 Ce 2 o 7 In the mol ratio of Y, Bi and Ce, yttrium chloride aqueous solution (concentration is 2.63mol / L) and bismuth chloride are added in the cerium chloride solution, obtain the solution containing metal element (in the solution containing metal element, cerium element as a benchmark, the molar concentration of cerium chloride is 0.975mol / L).

[0054] Prepare an aqueous ammonium bicarbonate solution with a concentration of 2 mol / L.

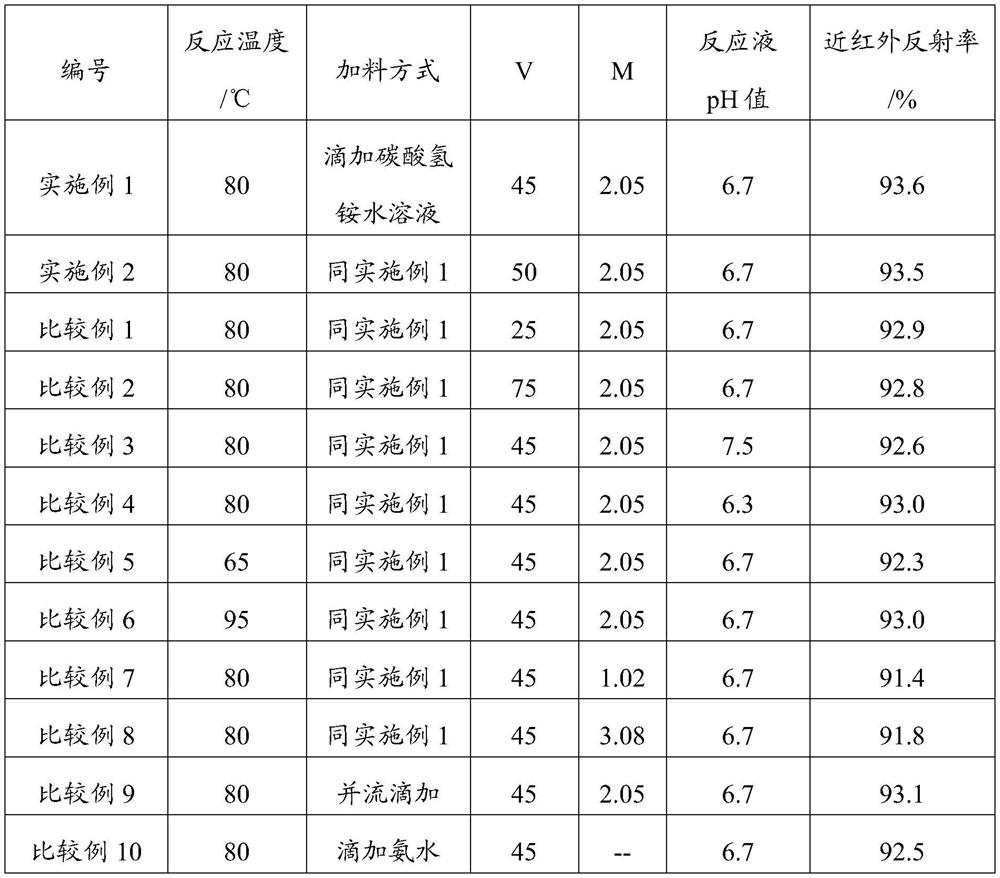

[0055] At 80°C, the ammonium bicarbonate aqueous solution was added dropwise to the solution containing metal elements at a feeding rate of 45mL / min for reaction, and the dropwise addition was stopped until the pH value of the reaction system was 6.7, and the reaction was continued for 0.5h to obtain a reaction solution , the pH value of the reaction solution was 6.7.

[0056] The reaction solution was filt...

Embodiment 2

[0058] The only difference from Example 1 is that the feeding rate of the ammonium bicarbonate aqueous solution is 50mL / min. The near-infrared reflectance results of the obtained yellow pigment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com