Mechanical dismantling device and dismantling method for high-rise building

A high-rise building and mechanical technology, applied in construction, building maintenance, building construction, etc., can solve problems such as inconvenient demolition, flying stones, dust effects, etc., and achieve the effect of improving demolition efficiency and demolition flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

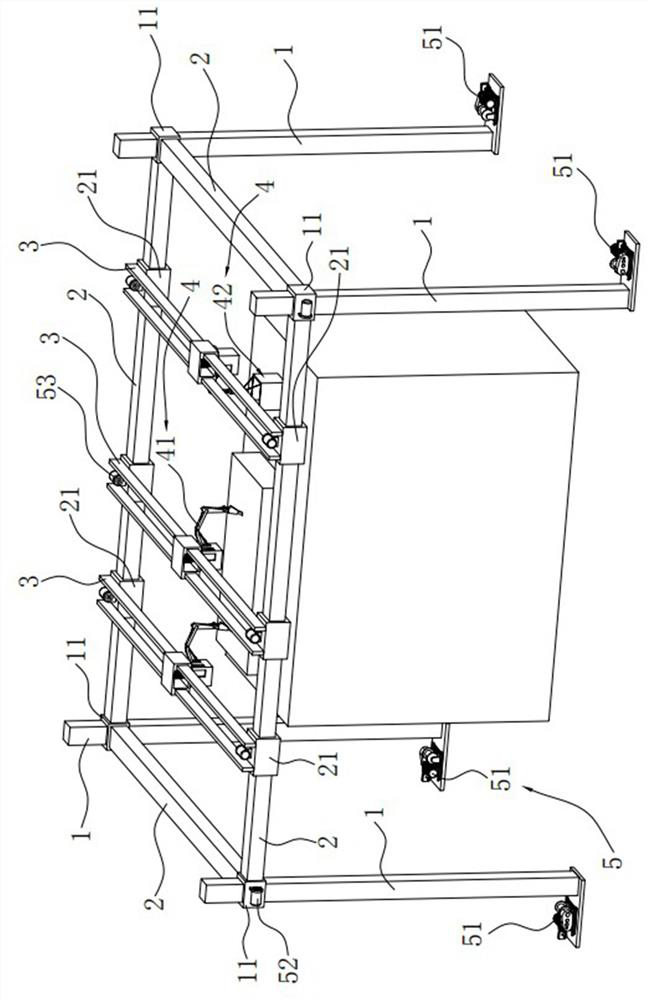

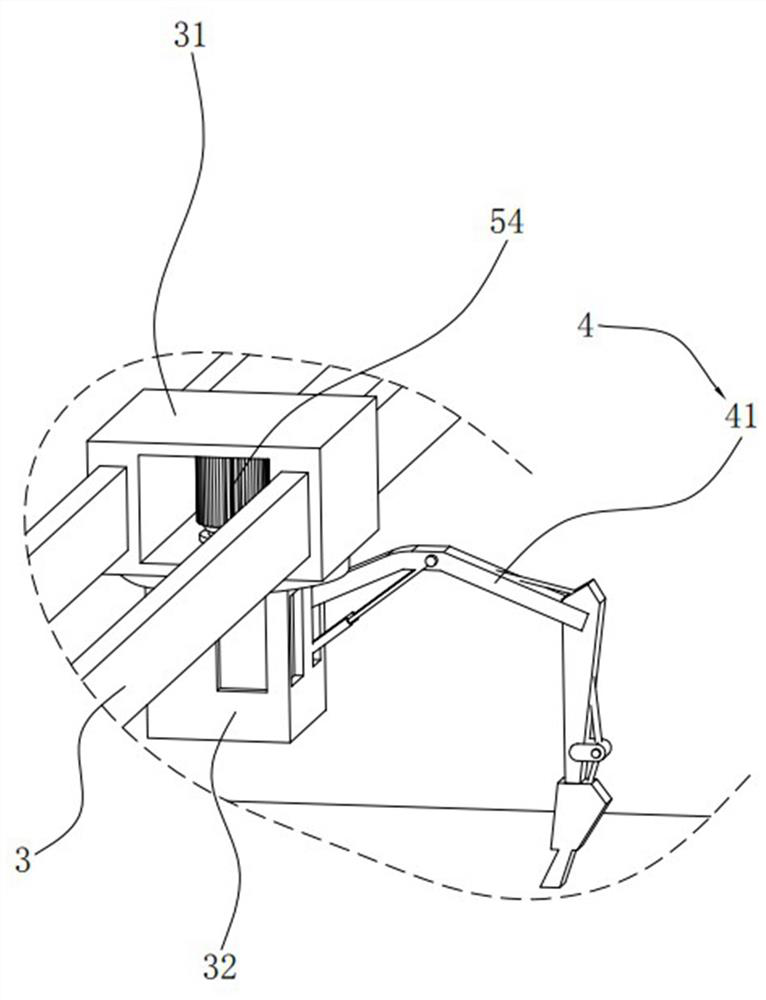

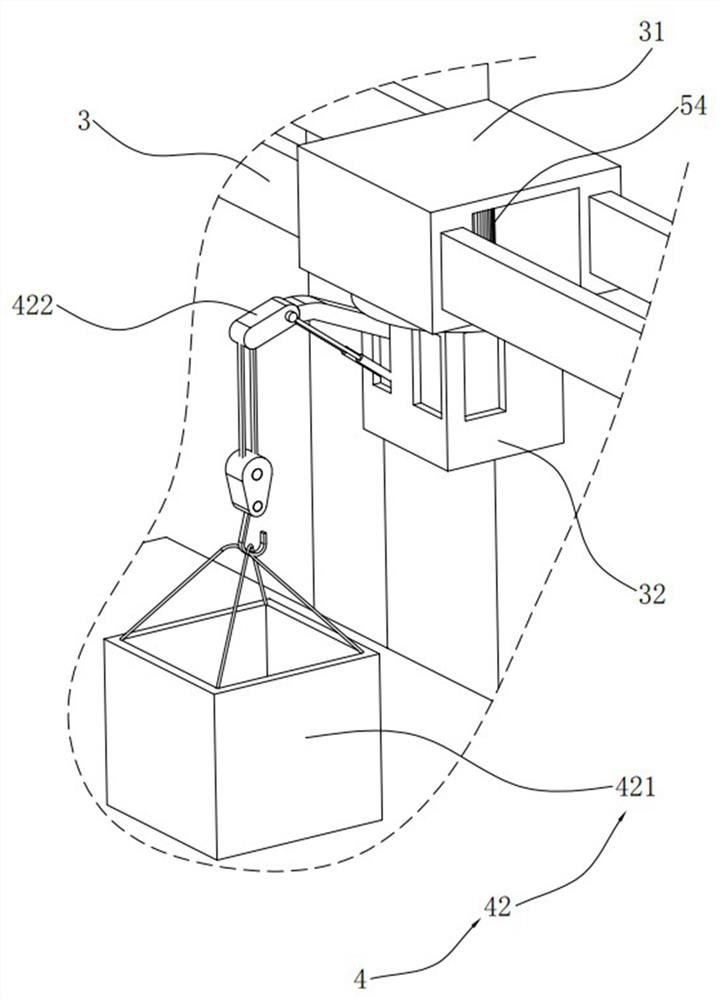

[0039] The following is attached Figure 1-3 The application is described in further detail.

[0040] The embodiment of the present application discloses a mechanical demolition device for high-rise buildings. refer to figure 1 , a mechanical demolition device for high-rise buildings, used to demolish high-rise buildings, comprising a truss main tower 1, a truss main beam 2, a steel frame secondary beam 3, a demolition assembly 4 and a drive assembly 5, the truss main beam 2 is arranged on the truss On the main tower 1, the steel frame secondary beam 3 is arranged on the truss main beam 2, the demolition assembly 4 is provided on the steel frame secondary beam 3, and the drive assembly 5 is used to drive the truss main beam 2 to slide on the truss main tower 1, and the steel frame The secondary beam 3 slides on the truss main beam 2 and the demolition assembly 4 slides on the steel frame secondary beam 3 .

[0041]During use, drive the truss main beam 2 to slide on the trus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com