A packer rubber cylinder and packer

A packer and rubber cartridge technology, applied in the field of packer rubber cartridges and packers, can solve problems such as unstable sealing of rubber cartridges, achieve increased expansion strength and sealing effect, long service life, and better sealing performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

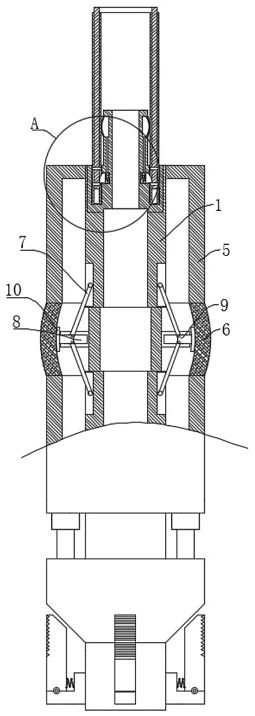

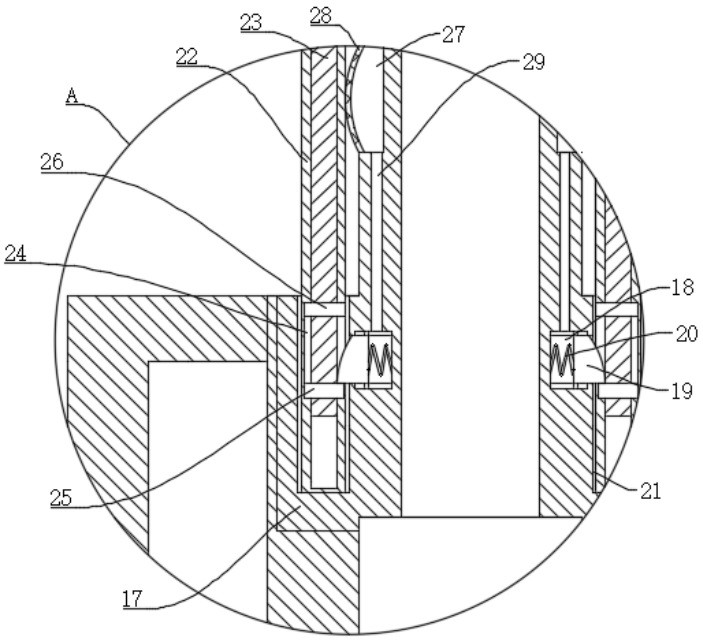

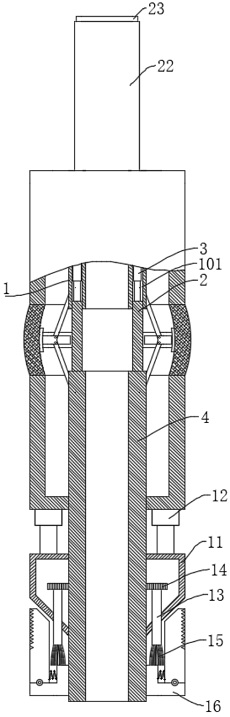

[0030] refer to Figure 1-4 , a packer rubber cylinder and a packer, comprising a first central pipe 1, an annular sliding groove 101 is opened inside the first central pipe 1, and a sliding cylinder 2 is slidably connected inside the annular sliding groove 101, and the sliding cylinder 2 A first hydraulic cylinder 3 is fixedly connected between one side of the sliding cylinder 2 and one side of the annular sliding groove 101, and a second central pipe 4 is fixedly connected to the other side of the sliding cylinder 2. The surface of the first central pipe 1 and the sliding cylinder 2 are fixedly connected. A first casing 5 is fixedly sleeved on the surfaces of the two first casings 5, a rubber cylinder 6 is fixedly connected between the adjacent sides of the two first casings 5, and the sliding cylinder 2 is fixedly connected with a spreader assembly, and the spreader assembly includes a guide block 8. The guide block 8 is fixedly installed on the surface of the sliding cylin...

Embodiment 2

[0040] refer to Figure 5 , a packer rubber barrel, including a packer, and also includes a rubber barrel 6, the rubber barrel 6 includes an upper rubber barrel 601, a middle rubber barrel 602 and a lower rubber barrel 603, and the upper rubber barrel 601, the middle rubber barrel 603 602 and the lower rubber cylinder 603 are fixedly connected in sequence from top to bottom; the rubber cylinder 6 is made of nitrile rubber, which has good high temperature and high pressure resistance. The shell 5 moves toward the middle, and the arc-shaped push plate 10 presses outward against the inner wall of the middle rubber cylinder 602, and the middle rubber cylinder 602 is soft and has good elasticity. When the cylinder 602 is used, the glue inside the middle rubber cylinder 602 flows to both ends, so that the middle part of the middle rubber cylinder 602 first bulges and closes to the oil production channel. When the barrel 602 expands outward, it drives the lower edge of the upper glu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap