Micro-channel heat exchange process and equipment

A heat exchange equipment and micro-channel technology, which is applied in heat exchange equipment, lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of troublesome maintenance, cleaning and disassembly of tubular heat exchangers, and achieve stable and safe mechanical heat dissipation. , The effect of facilitating the disassembly of mechanical equipment and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

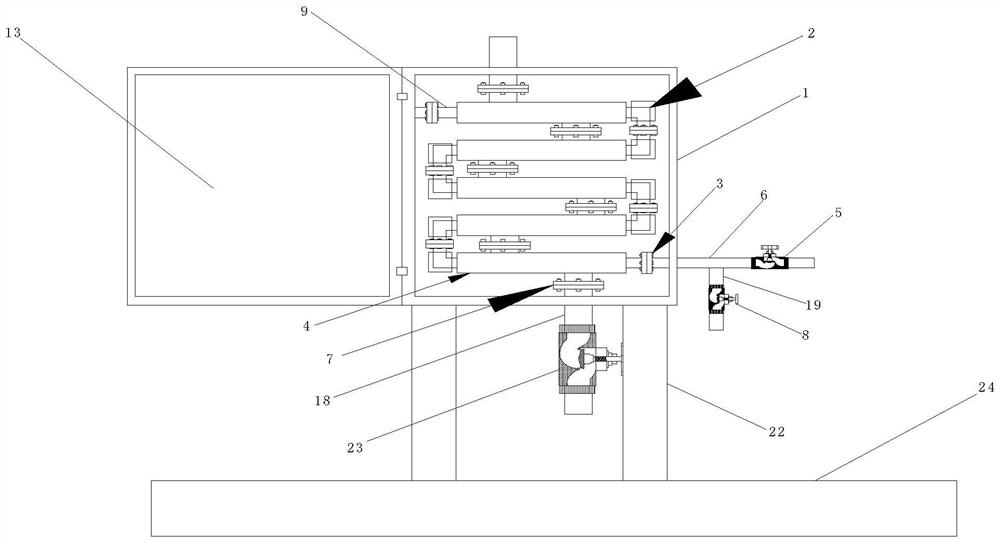

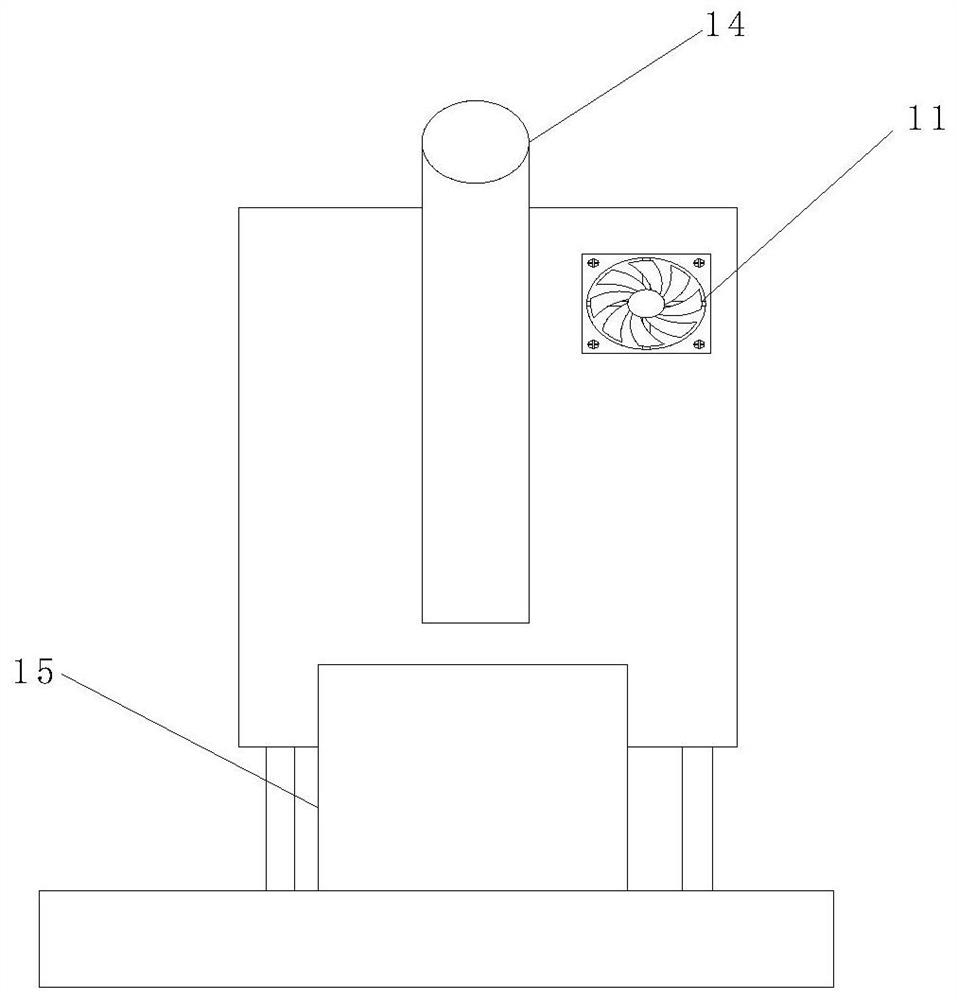

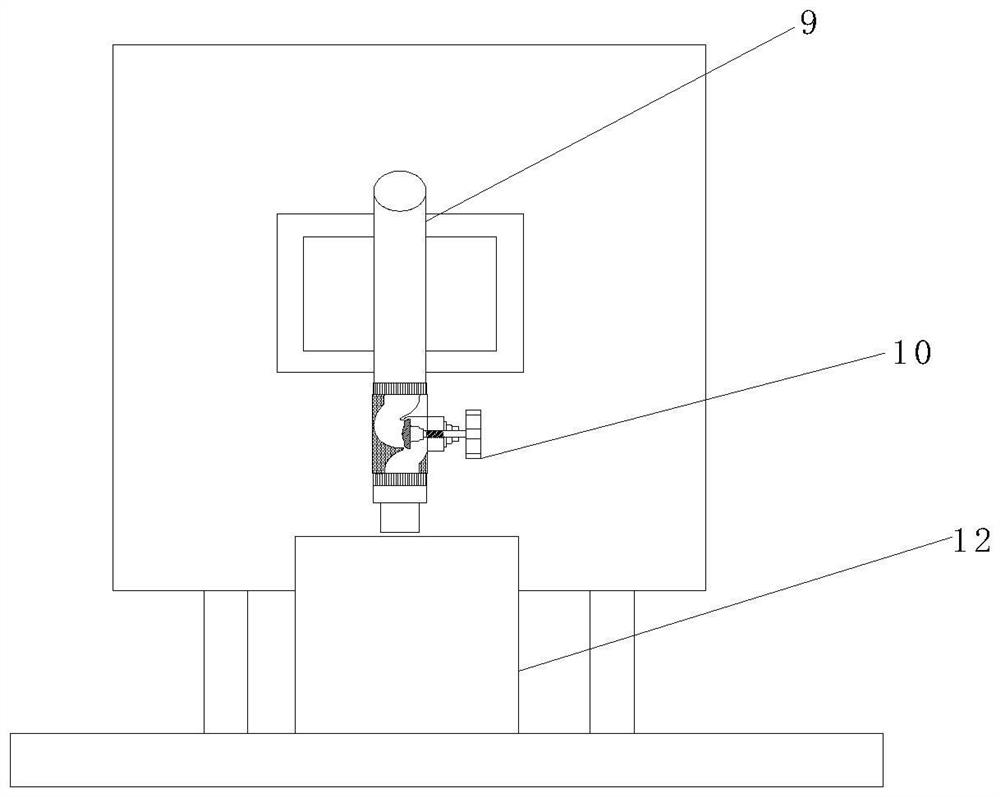

[0041] Such as Figure 1-17As shown, the present invention provides a process scheme: a kind of microchannel heat exchange equipment, including a first worktable 24, the top of the first worktable 24 is fixedly connected with a coolant recovery bucket 15, and the coolant recovery bucket 15 The top surface is perpendicular to the fifth channel pipe 14, the top of the first worktable 24 is fixedly connected with the hot liquid recovery bucket 12, and the top surface of the hot liquid recovery bucket 12 is perpendicular to the fourth channel pipe 9, and the top of the first workbench 24 The top is fixedly connected with box support legs 22, the number of box support legs 22 is four, the top of box body support legs 22 is fixedly connected with box body 1, and the number of internal group A devices of box body 1 is two, box body 1 The number of group B devices inside the body 1 is three. The group A device includes the first removable disk device 3, the second removable disk devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com