Plastic film production defect detection method and system based on image processing

A defect detection and image processing technology, applied in image data processing, image analysis, image enhancement, etc., can solve the problems of heavy workload, impact of brightness changes, high missed detection rate, etc., to achieve accurate acquisition and reduce gray level change errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

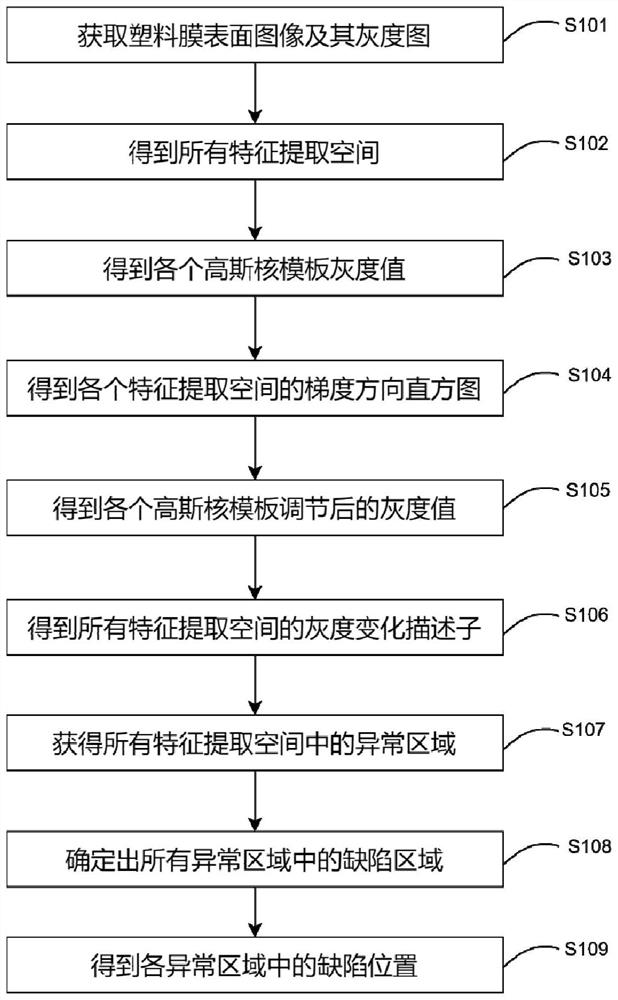

[0050] An embodiment of the present invention provides a method for detecting defects in plastic film production based on image processing, such as figure 1 shown, including:

[0051] S101. Acquire the surface image of the plastic film and its grayscale image.

[0052] Among them, the grayscale image is also called the grayscale image. The logarithmic relationship between white and black is divided into several levels, called gray scale. The gray scale is divided into 256 levels.

[0053] S102. Divide the grayscale image into regions to obtain all feature extraction spaces.

[0054] Among them, the feature extraction space is equivalent to dividing the entire grayscale image into blocks.

[0055] S103. Perform Gaussian kernel convolution on each feature extraction space to obtain the gray value of each Gaussian kernel template.

[0056] Among them, the convolution operation is to slide the convolution kernel from left to right and from top to bottom in the form of a windo...

Embodiment 2

[0073] The main purpose of this embodiment is to detect production defects in the plastic film production process through the plastic film image and the set light source.

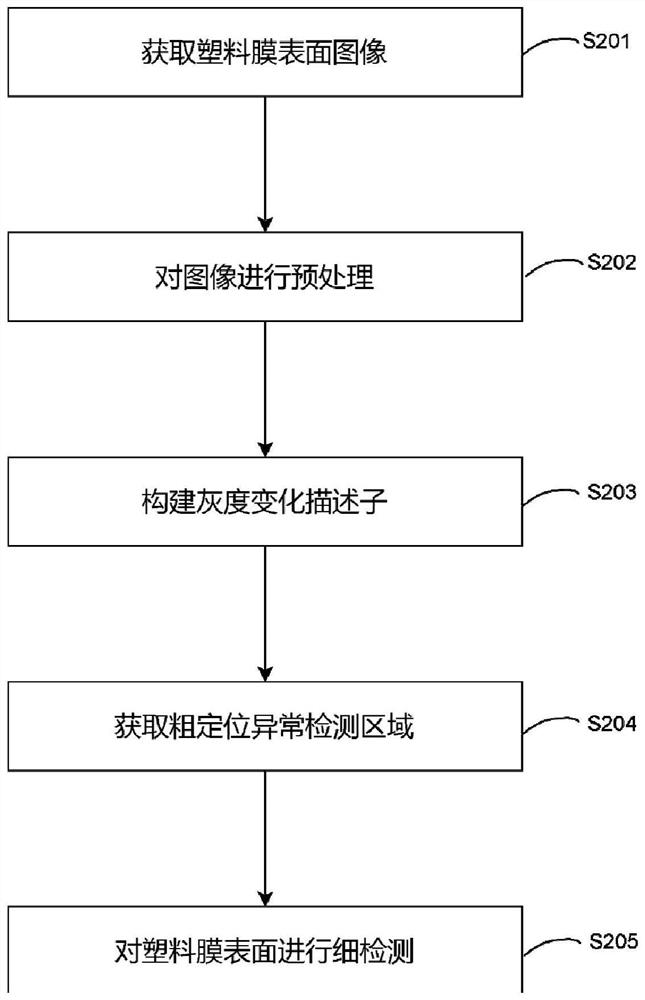

[0074] An embodiment of the present invention provides a method for detecting defects in plastic film production based on image processing, such as figure 2 shown, including:

[0075] S201. Add an external light source to acquire a surface image of the plastic film.

[0076] By installing an image acquisition device at the entrance of the coiler, the image acquisition device includes: a common RGB camera and a planar light source. The surface of the plastic film is illuminated by a planar light source, and the surface image of the plastic film is collected by the camera. The positions of the planar light source and the camera are fixed, and there is no effect of scattering on the light source. The detection object is a white transparent plastic film, and the main defects are: gel defects.

[0077] S202...

Embodiment 3

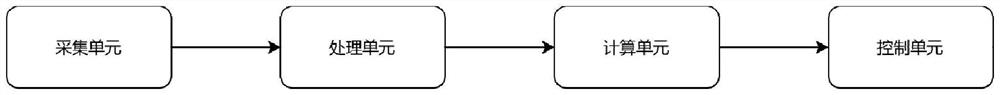

[0106] Embodiments of the present invention provide a plastic film production defect detection system based on image processing, such as image 3 As shown, including acquisition unit, processing unit, calculation unit and control unit:

[0107] The acquisition unit sets the camera directly above the entrance of the coiler to collect the surface image of the plastic film on the production line;

[0108] The processing unit inputs the image collected by the acquisition unit into the data master, and uses the data master to preprocess the image to obtain a grayscale image of the surface of the plastic film; perform feature extraction on the grayscale image to obtain the grayscale of the plastic film The change descriptor, according to the gray scale change descriptor, evaluates the defects of the plastic film, and obtains the rough positioning abnormal area;

[0109] The calculation unit uses the data master to process the abnormal area obtained by the processing unit with an en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com