Glue injection mechanism and injection molding machine

A technology of glue injection and glue injection head plate, applied in the field of glue injection mechanism and injection molding machine, which can solve the problems of low installation position accuracy, incomplete installation, and inability to install parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

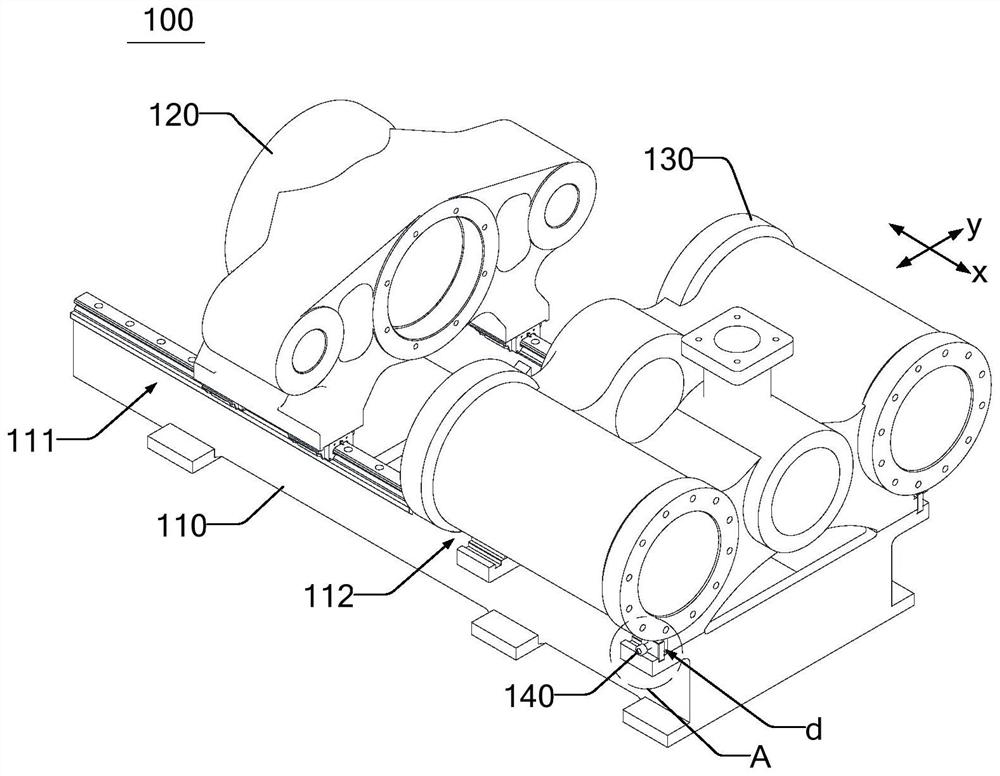

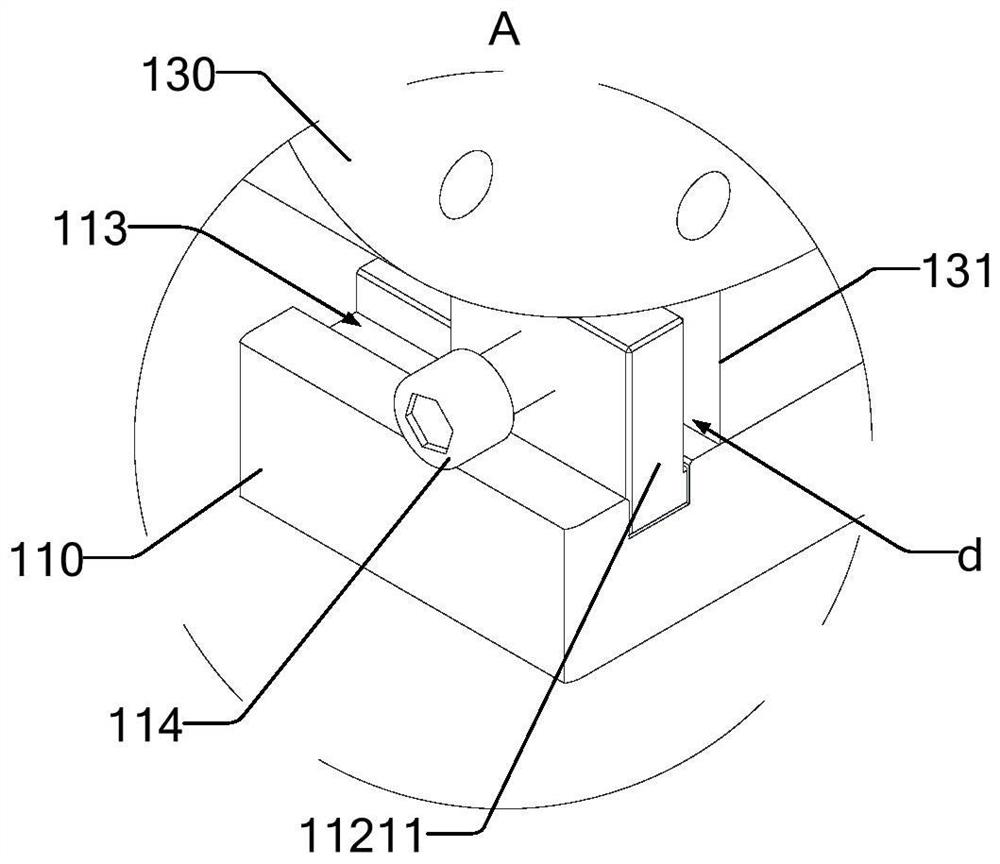

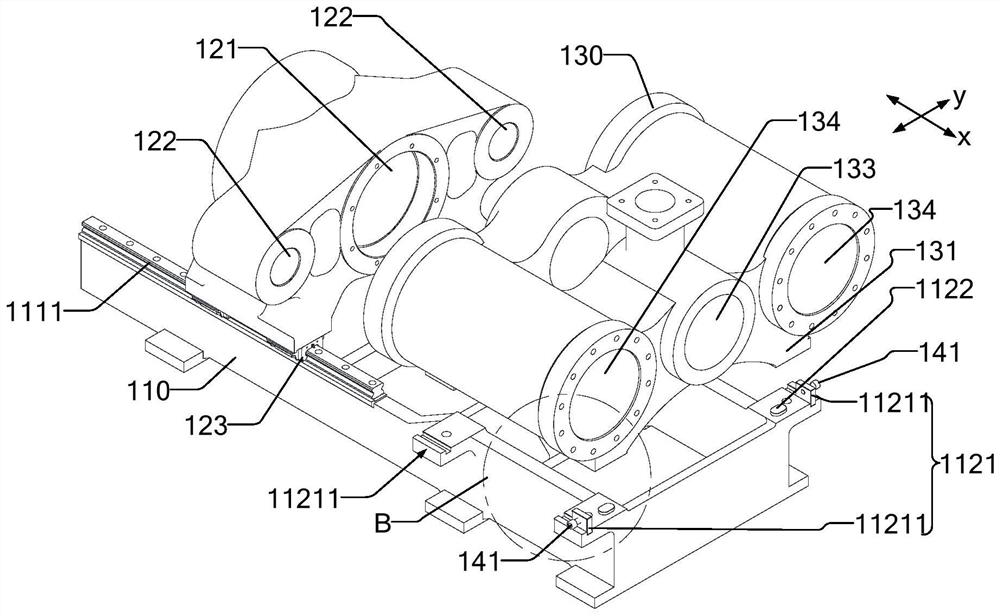

[0079] like Figure 1 to Figure 8 As shown, this embodiment proposes a glue injection mechanism 100 , including a base 110 , a glue injection tail plate 120 , a glue injection head plate 130 and an adjustment structure 140 .

[0080] Two injection oil cylinders are arranged on the injection head plate 130, and the specifications of the two injection oil cylinders are consistent and symmetrical to each other. The injection head plate 130 and the base 110 are fixed by screws. The base 110 is equipped with a linear slide rail 1111. The injection tail plate 120 is provided with a sliding part 123 and is slidably connected to the linear slide rail 1111 through the sliding part 123. The injection tail plate 120 is movable on the base 110 .

[0081] The glue injection tail plate 120 is connected with the piston rod of the glue injection cylinder by a nut, and the piston rod of the glue injection cylinder and the piston of the glue injection cylinder are connected by threads. The two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com