Porous adjustable variable load hydraulic buffer

A hydraulic shock absorber, adjustable technology, applied in the field of hydraulic shock absorbers, can solve the problems of inability to shock buffer, impact additional peak buffer performance is not very good, performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

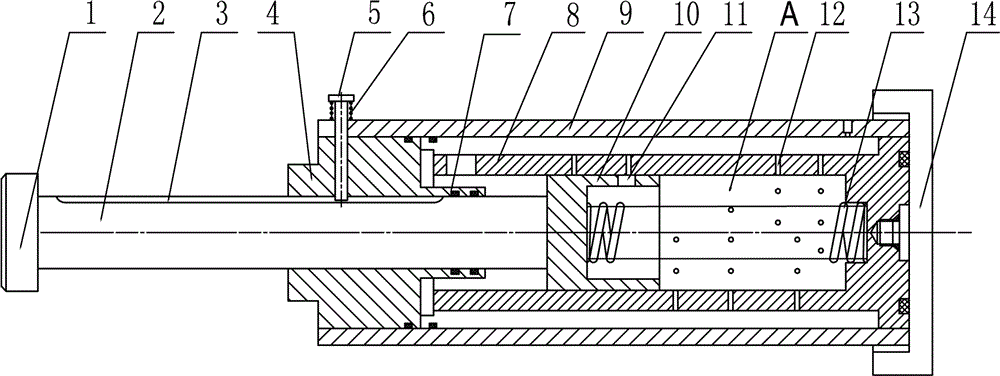

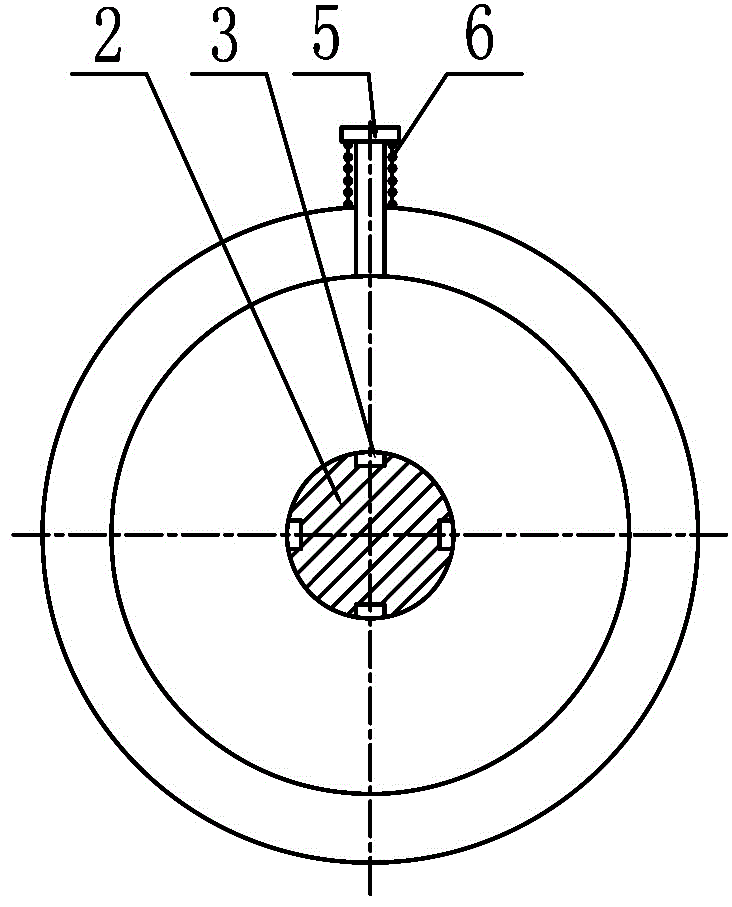

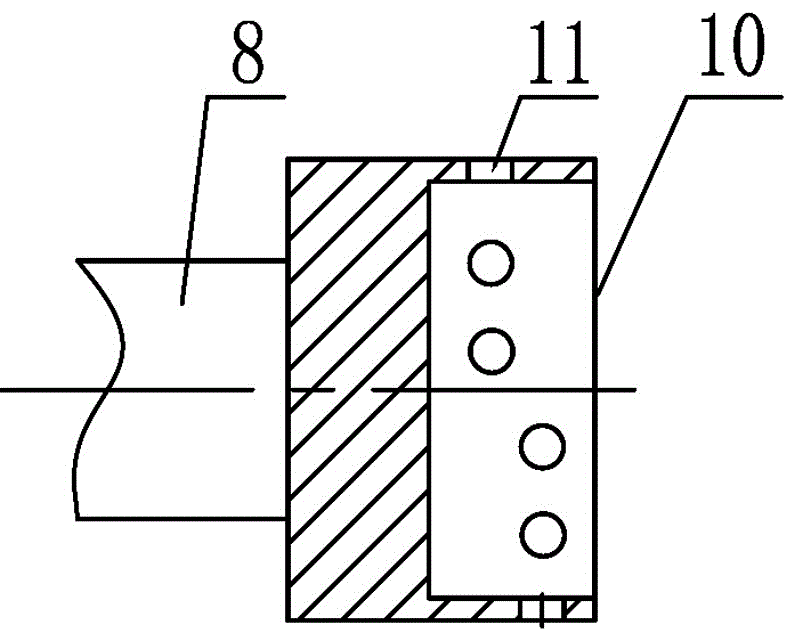

[0019] The structure of the present invention is as figure 1 -3 shows: a porous adjustable variable load hydraulic buffer, including a base 14, an inner cylinder 8, an outer cylinder 9 and the base 14 are rigidly connected concentrically; the inner cylinder 8 is circumferentially directed to the inner cylinder damping hole 12; The piston 10 is connected to the bottom of the inner cylinder 8, and the piston rod 2 is connected to the piston 10. The piston rod 2 and the piston 10 reciprocate under the action of the return spring 13 and the load. A piston damping hole 11 is opened on the outer wall of the piston 10. An adjustment knob 1 is provided, and the adjustment knob 1 can adjust the angle direction of the piston 10. The positioning pin 5 passes through the outer cylinder 9 and the end cover 4 to cooperate with the guide groove 3 on the piston rod 2, and through the guide groove of the piston rod 2, the piston 10 rotation direction positioning.

[0020] When the piston 10 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com