Ceramic tile production line achieving automatic foam particle scattering

A foam particle and production line technology, applied in the field of ceramic tiles, can solve the problems of uneven feeding, damaged brick surface, crushed tiles, etc., and achieves the effect of mature technology, easy opening and closing operation, and avoiding direct pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

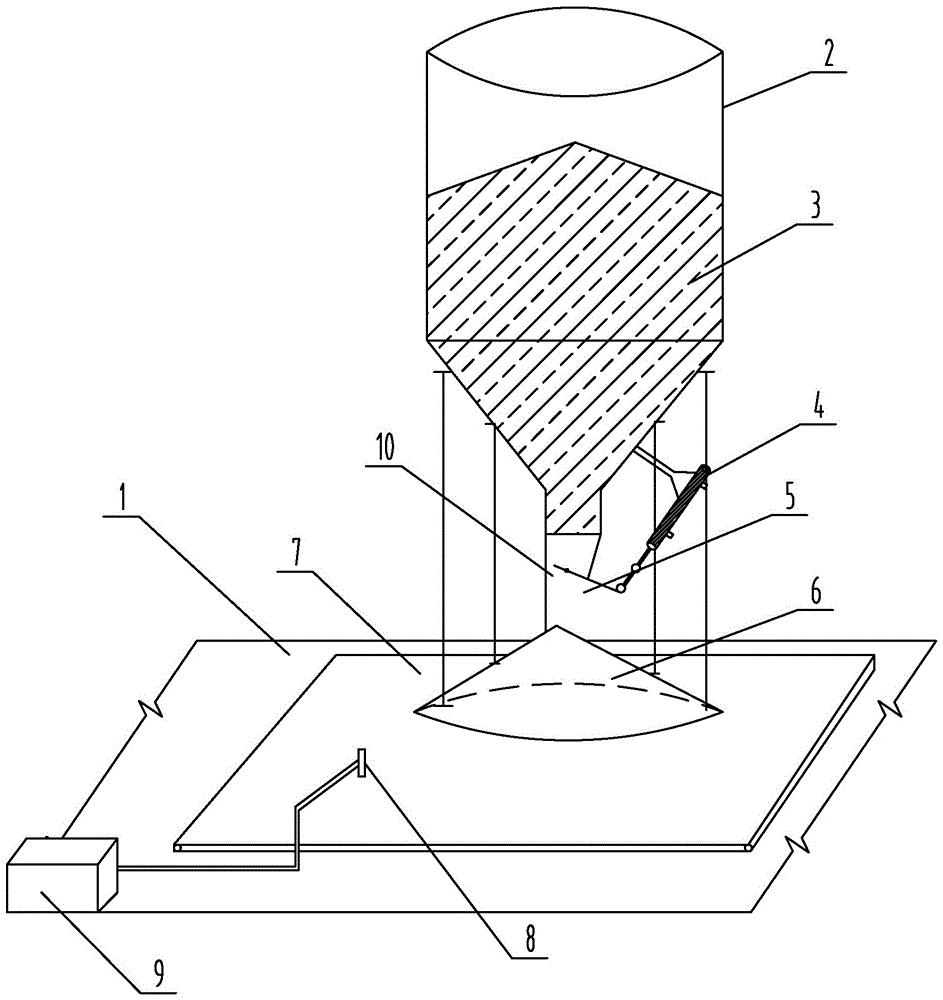

[0025] Such as figure 1 As shown, the present invention arranges a foam distributing device above the tile conveyor belt 1, and a silo 2 is arranged in the foam distributing device. on the bottom wall. Distributing mouth 10 is hinged with flashboard 5, and flashboard 5 is connected with cylinder 4, and cylinder 4 controls flashboard 5 to rotate and realizes its opening and closing; A tile detection sensor 8 and a controller 9 are also arranged in the foam distributing device. The tile detection sensor 8 detects the tiles 7 on the tile conveyor belt 1 and transmits the detection signal to the controller 9. The controller 9 controls according to the detection signal of the tile detection sensor 8. The actuator acts to control the opening time of the gate 5 .

[0026] Working process of the present invention is as follows:

[0027] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com