Swinging processing platform and filter processing device

A technology of processing platform and processing device, which is applied to grinding drive devices, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to realize horizontal and vertical directions, and two-way rotation at the same time, so as to improve the processing range and improve the adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

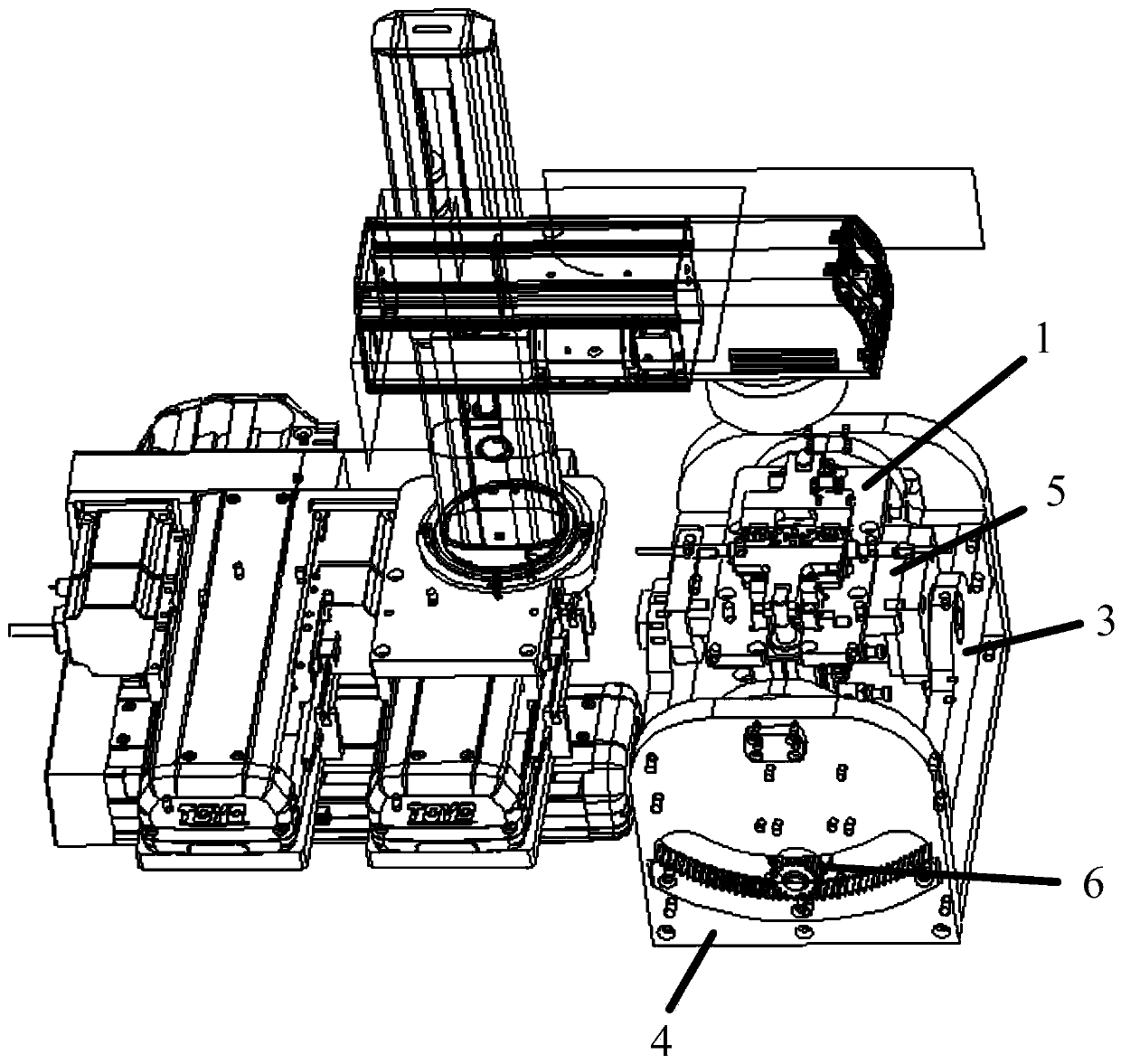

[0055] This embodiment provides a filter processing device, such as figure 1 As shown, it includes: a swing processing platform that can be driven to rotate along the transverse and longitudinal directions of the filter; and a grinding mechanism 22 for grinding the resonant cavity of the ceramic filter.

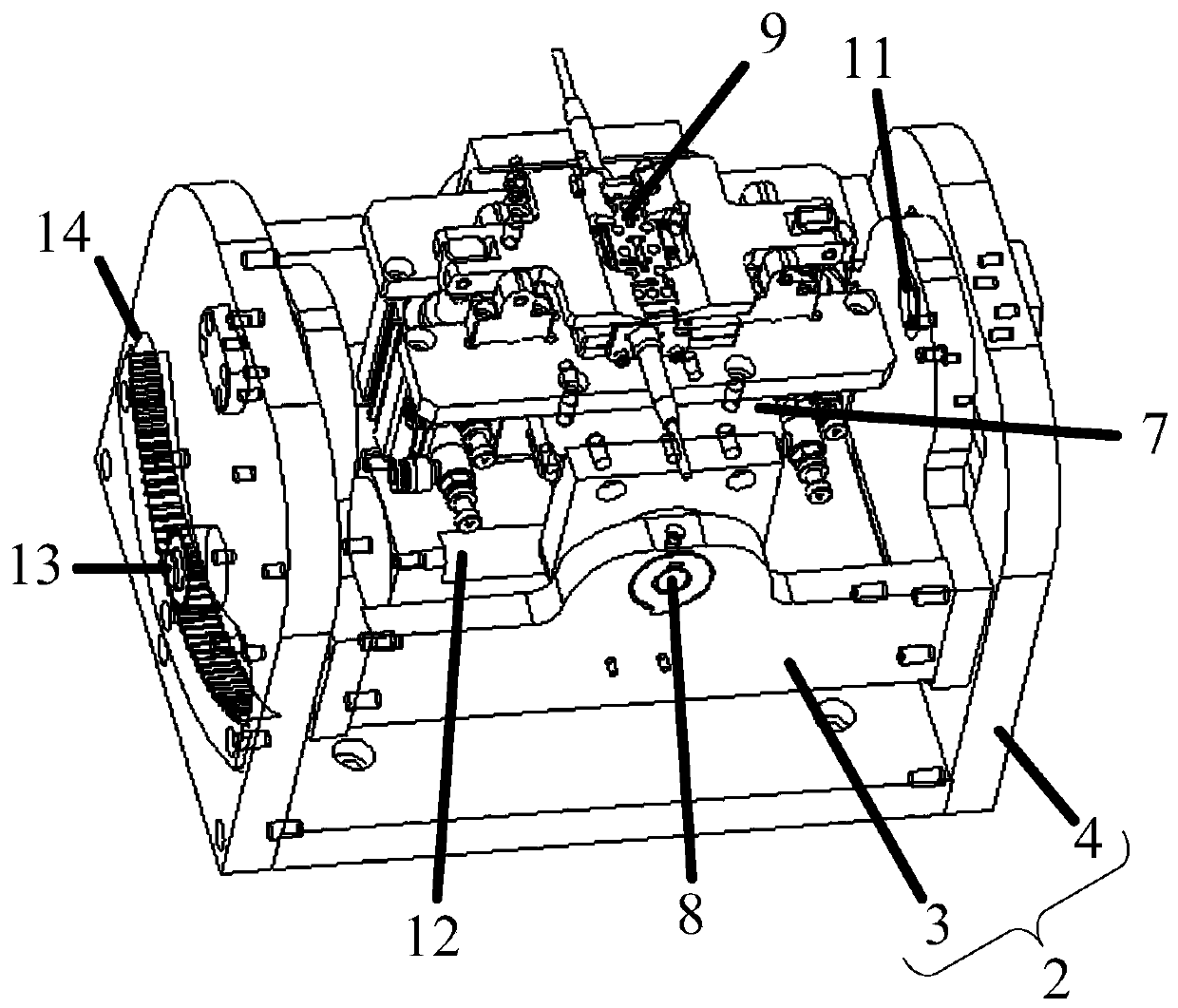

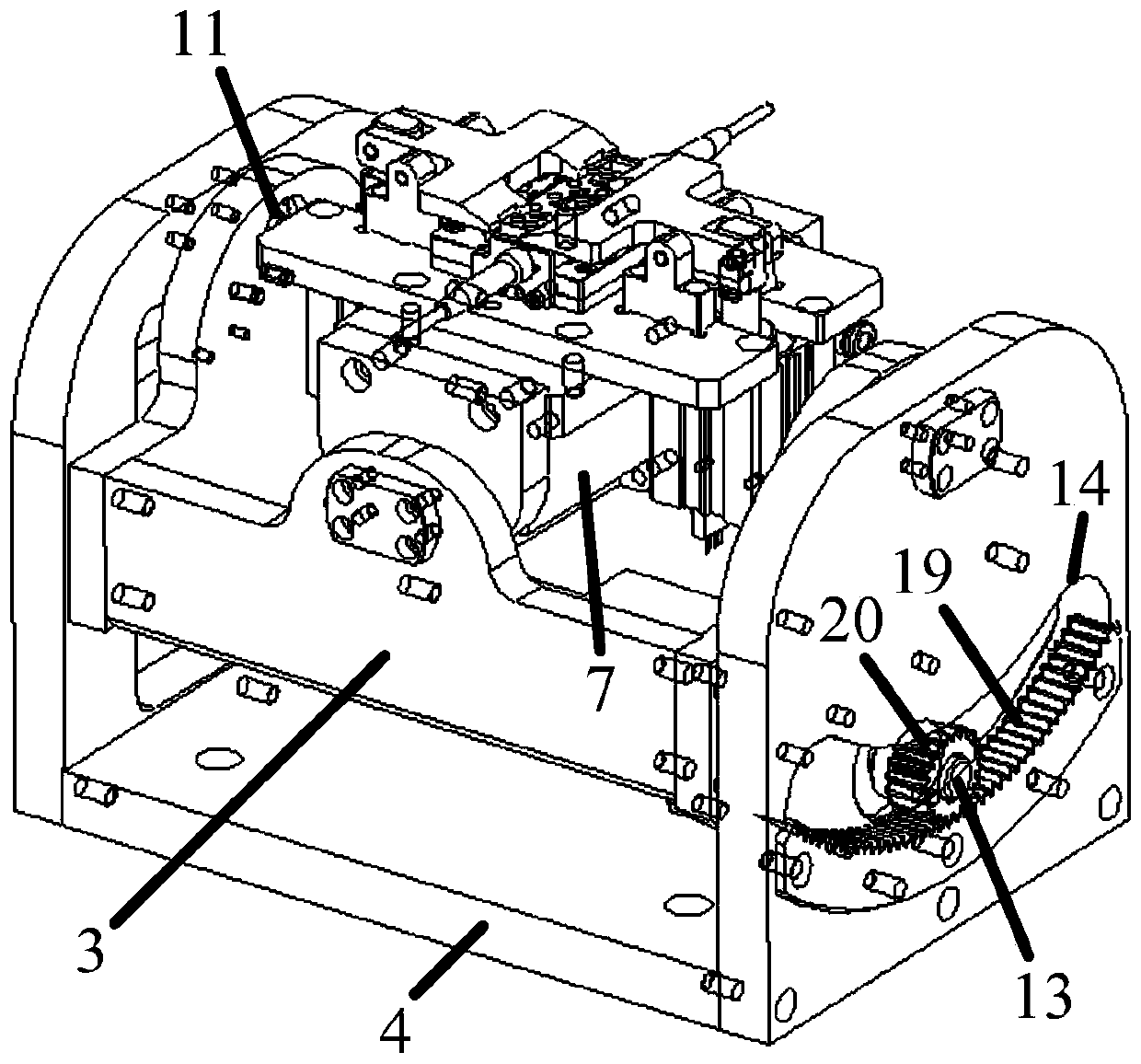

[0056] Swing processing platform, such as figure 2 with image 3 As shown, it includes:

[0057] The workpiece processing table 1 includes a platform for supporting the workpiece 9;

[0058] The support frame 2 includes a first turret 3 and a second turret 4, the first turret 3 is rotatably arranged on the second turret 4, and is driven to process the workpiece The table 1 rotates in the first direction; the workpiece processing table 1 is rotatably arranged on the first turret 3, and is driven to rotate in the second direction of the workpiece processing table 1; the workpiece processing table 1 passes The first drive shaft 8 and the first support shaft are rotatably arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com