A kind of rowing machine button test equipment and test method

A technology of testing equipment and rowing machines, which is applied in the testing of mechanical components, testing of machine/structural components, testing of circuit breakers, etc. It can solve the problems of poor testing accuracy, high cost, and reduced testing efficiency, and improve testing accuracy , Improve test efficiency and save test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

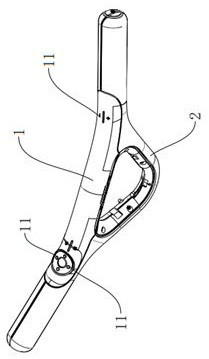

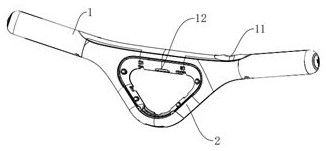

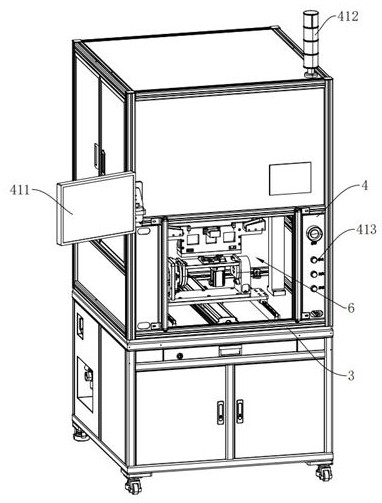

[0062] The embodiment of the present application discloses a device for testing the keys of a rowing machine. refer to Figure 1-6 , a rowing machine key test equipment, including a test machine 3, a PLC controller 4, a test assembly 5 for testing the control keys 11, and a multi-axis flip fixing assembly 6 for fixing the flip test piece. The PLC controller 4 , the test assembly 5 and the turning and fixing assembly 6 are all fixedly installed on the testing machine 3 , and the testing assembly 5 and the turning and fixing assembly 6 are all connected to the PLC controller 4 . The PLC controller 4 is connected with a peripheral component 41 , and the peripheral component 41 is fixedly installed on the testing machine 3 . The testing assembly 5 includes an X-axis module 51 that moves laterally along the testing machine 3 , a Z-axis module 52 that moves along the height direction of the testing machine 3 , and a testing component 53 for performing pressure testing on the keys. ...

Embodiment 2

[0085] refer to Figure 10-12 The difference between this embodiment and the first embodiment is that the test component 53 further includes a water source 533 , a water spray pipe 534 , a micro atomizing pump 535 and a current sensor 536 . The water source 533 is connected to the water inlet of the micro atomizing pump 535 , and the water spray pipe 534 is connected to the water outlet of the micro atomizing pump 535 . One end of the water spray pipe 534 is disposed toward the test probe column 531 and is fixedly connected with the atomizing spray head 537 . The detection end of the current sensor 536 is connected to the outer surface of the test probe post 531 . Through the settings of the water source 533 , the water spray pipe 534 , the micro atomizing pump 535 and the current sensor 536 , it is possible to simulate the use situation of the user operating the keys with wet hands during the key press test, and to detect whether the test piece will leak electricity during u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com