Plate conveying equipment and method based on visual monitoring and intelligent grabbing

A technology for visual monitoring and conveying equipment, applied in the field of sheet metal processing, can solve problems such as difficulty in adapting to sheets and different shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

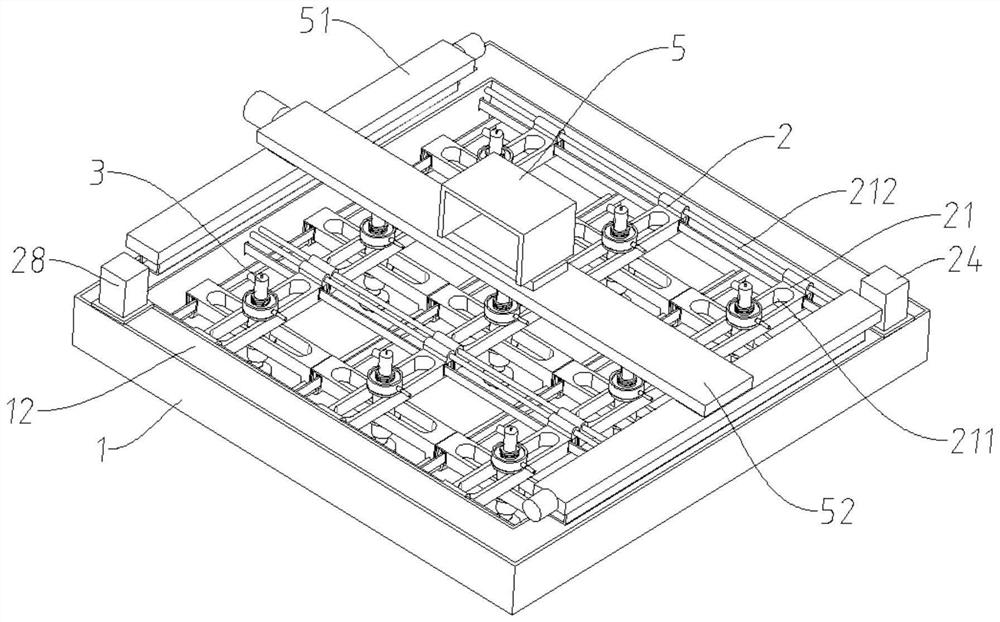

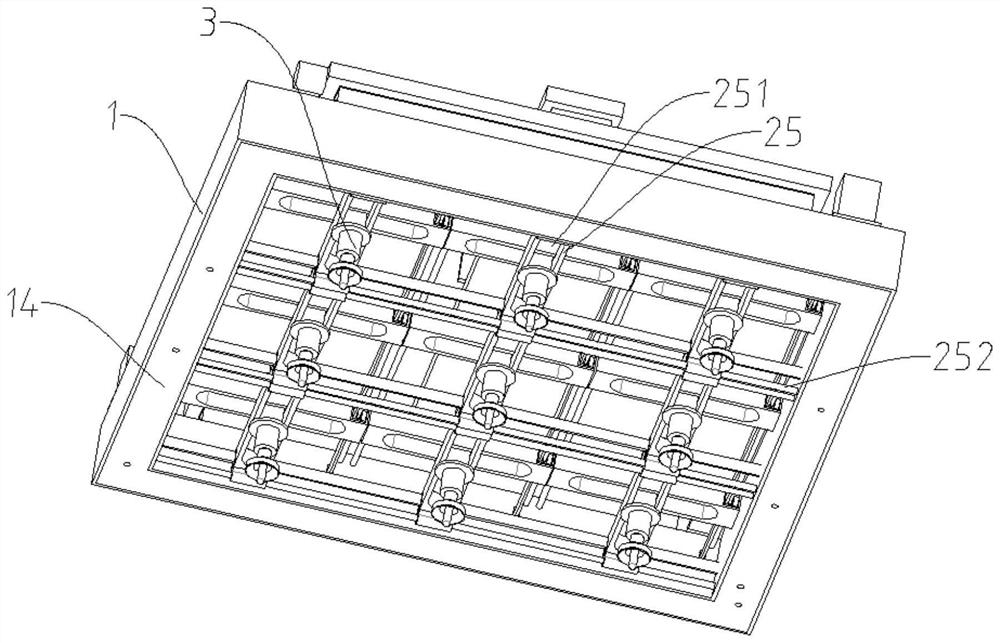

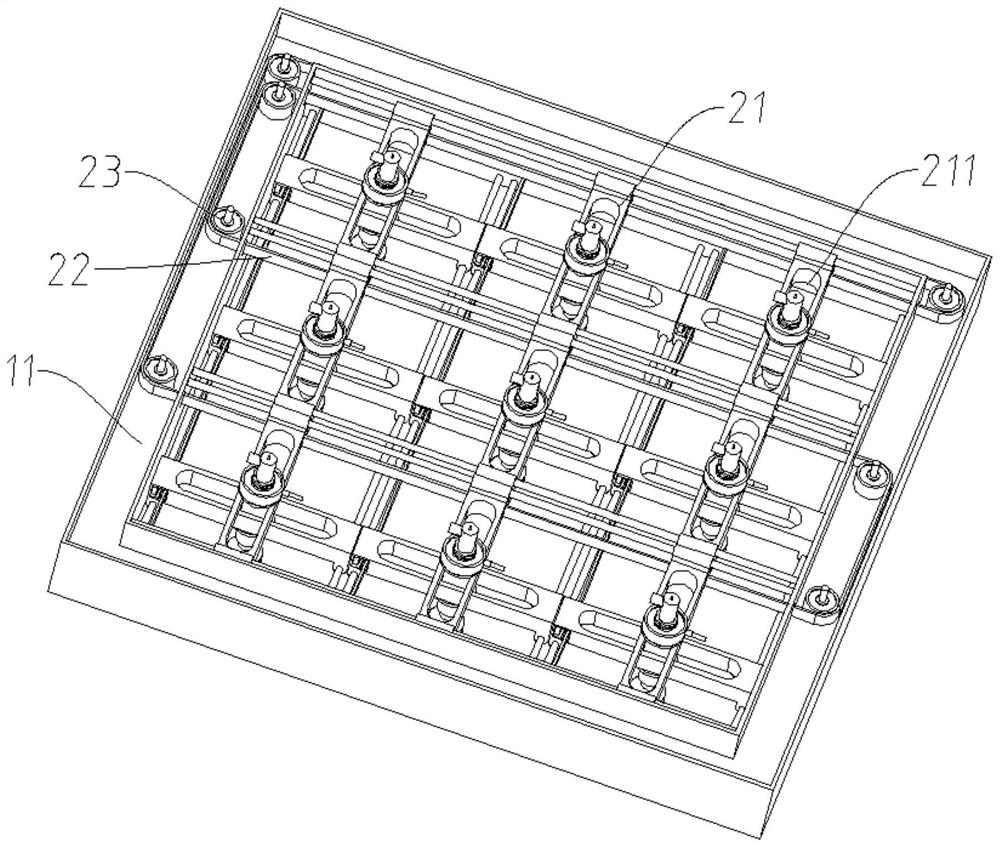

[0050] like Figure 1-8As shown, a plate conveying device based on visual monitoring and intelligent grasping includes an installation frame 1 and a plurality of suction cup assemblies 3 mounted on the installation frame 1, and the plurality of suction cup assemblies 3 can move relative to the installation frame 1 and different suction cup assemblies 3 The movements of the suction cups are independent of each other, the suction cup assembly 3 can be moved to the required position to suck up the board, and the suction cup assembly 3 is driven by the drive assembly 2 .

[0051] The suction cup assembly 3 includes a suction cup 31 , an air guide cylinder 32 , and an installation cylinder 33 . The working end of the suction cup 31 faces downwards. The upper end of the air guide cylinder 32 is communicated with the negative pressure device through a pipeline, so as to realize the adsorption of the plate. The installation cylinder 33 is sleeved on the air guide cylinder 32 and the ...

Embodiment 2

[0070] This embodiment is the use method of the first embodiment, which specifically includes the following steps:

[0071] Step 1: the plate conveying equipment is moved to the top of the plate;

[0072] Step 2: the camera 310 of each suction cup assembly 3 takes a picture of the plate, and judges whether there is a plate that can be sucked up directly below each suction cup assembly 3 according to the photographed picture;

[0073] Step 3: If there is a plate that can be sucked up directly under each suction cup assembly 3, the plate conveying device moves downward until all the suction cup assemblies 3 suck the plate;

[0074] Step 4: Move the plate conveying equipment to move the plate to the required position.

[0075] When performing step 3, if there is no sheet for suction directly below part of the suction cup assembly 3, perform the following steps:

[0076] Step 3.1: According to the photographed pictures, determine whether the suction cup assembly 3 without the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com