Portable Fluid Delivery Systems & Kits

A fluid delivery system and fluid delivery technology, applied in fluid treatment accessories, fluid treatment, fluid transfer, etc., can solve problems such as the impact of lifting thrust, and achieve the effects of less energy consumption, easy portability, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

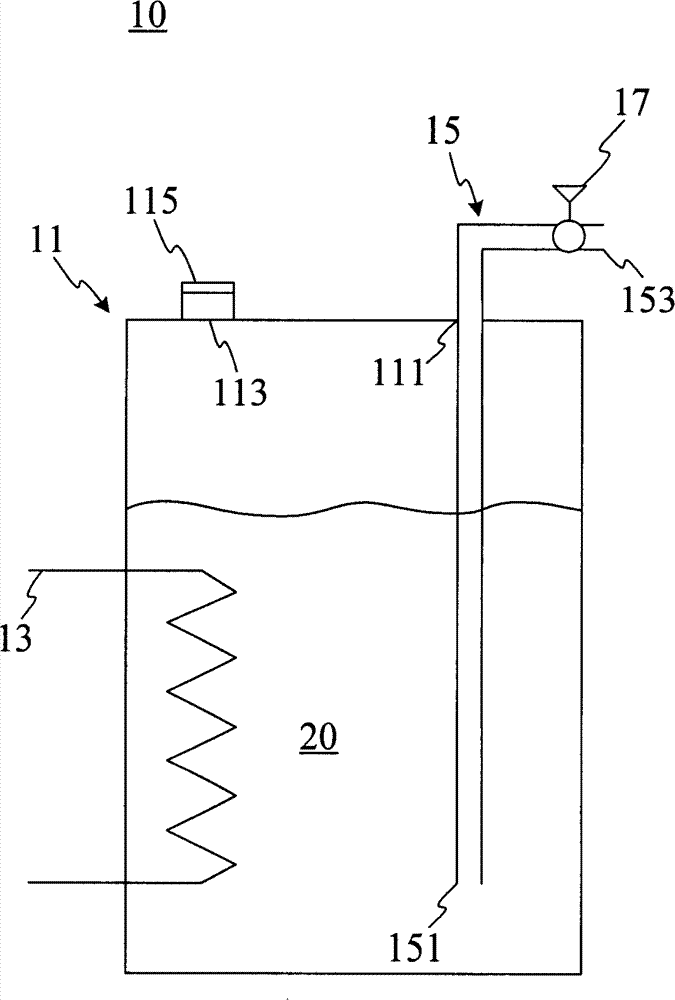

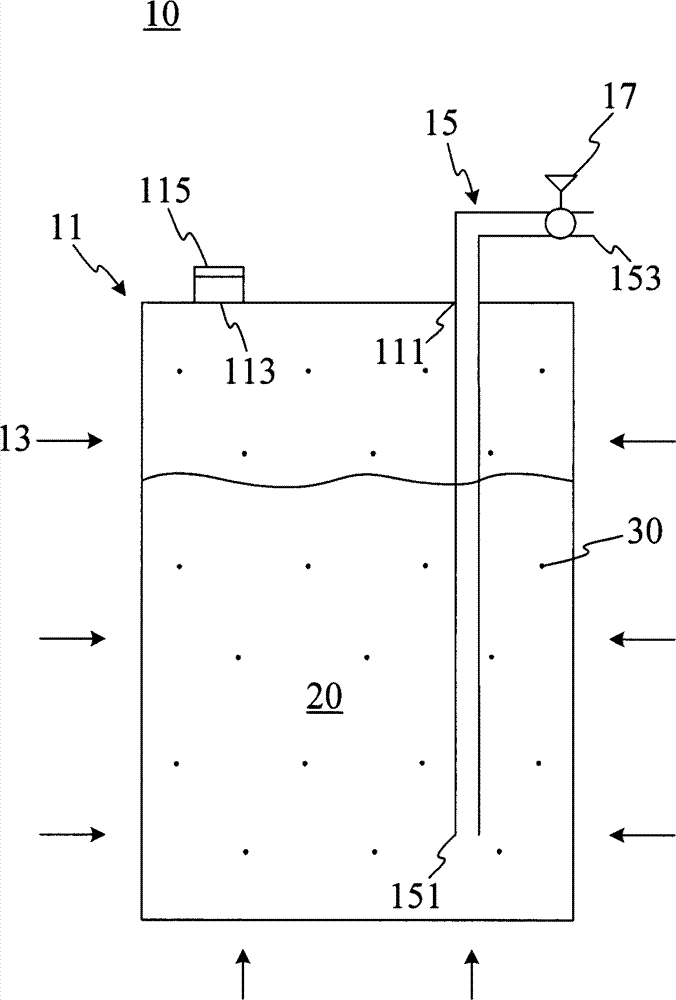

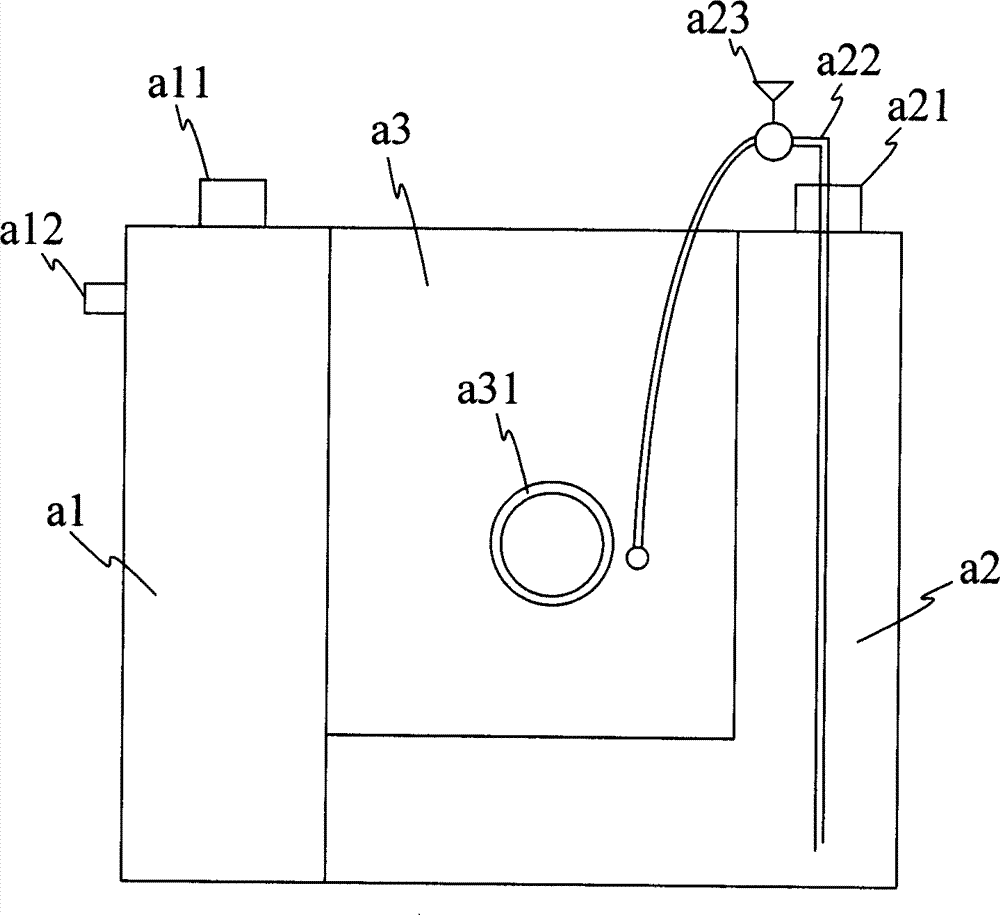

[0015] A preferred embodiment of the present invention is figure 1 As shown, the fluid delivery system 10 includes a container 11 , a heat source 13 , and a delivery line 15 . Wherein, the container 11 has a discharge hole 111 and an accommodating space, and preferably must withstand pressure, and the degree of pressure resistance depends on operating conditions (including operating temperature, fluid type, etc.). The accommodating space is for accommodating a liquid to be transported 20 which is liquid at normal temperature, and the transport pipeline 15 is connected to the discharge hole 111 . When the fluid delivery system 10 is in operation, except the delivery pipeline 15 becomes an external channel, the container 11 is in a closed state substantially, and part of the fluid 20 to be delivered is discharged from the fluid delivery system through the discharge hole 111 along the delivery pipeline 15 10 outside.

[0016] More specifically, the delivery pipeline 15 may incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com