Warehouse logistics sorting robot based on Internet of Things

A warehousing logistics and robot technology, applied in the field of warehousing and sorting, can solve the problems of reducing sorting efficiency and increasing sorting time, and achieve the effect of improving sorting efficiency and expanding scanning area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

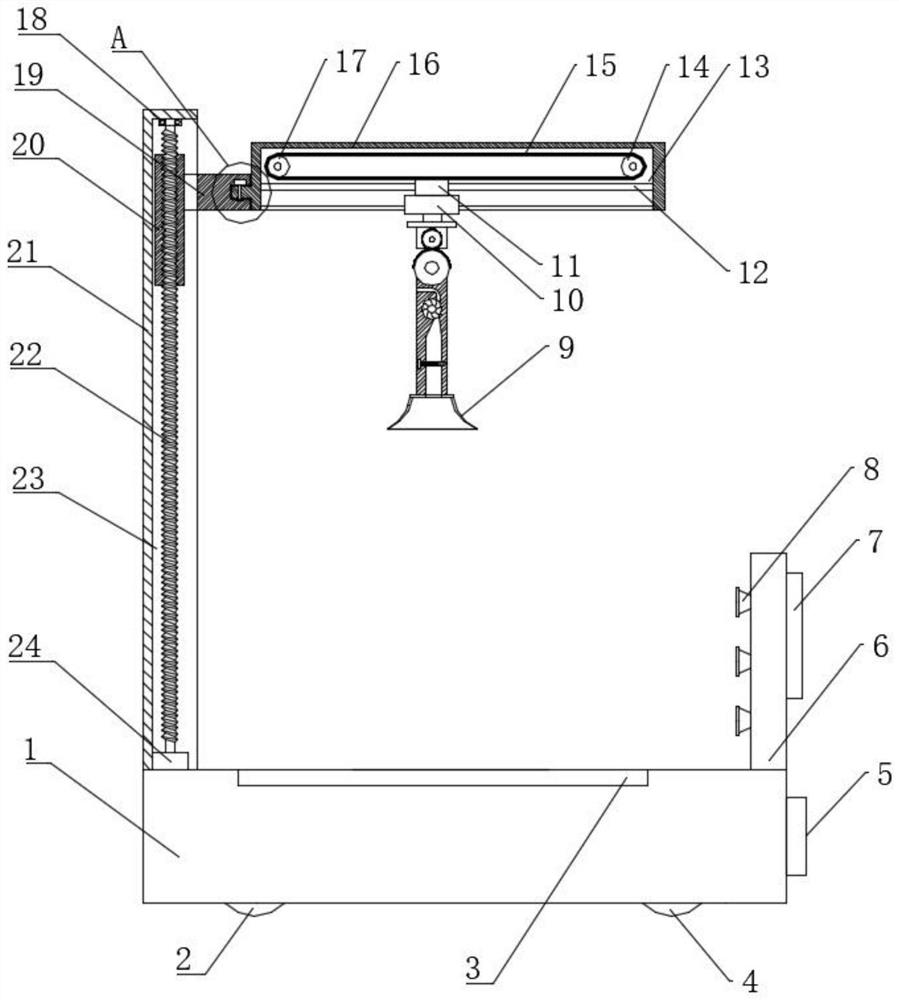

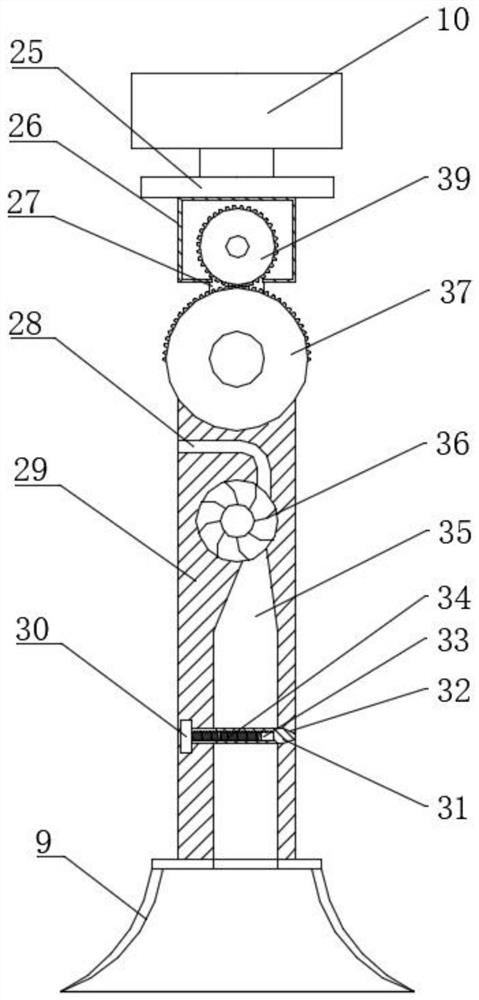

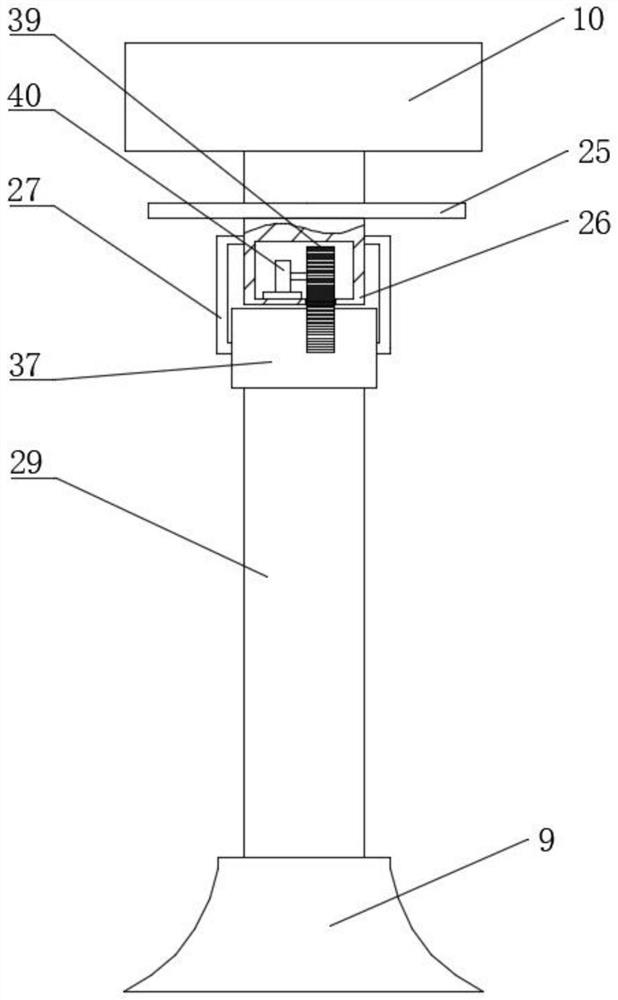

[0038] Example: an IoT-based warehousing logistics sorting robot, such as Figure 1 to Figure 6 As shown, it includes a control box 1, a side plate 21 and a baffle 6; a control processor 63, a battery 62 and a mobile device are fixedly installed in the control box 1, and the top ends of the control box 1 are respectively connected to the side The bottom of the plate 21 and the bottom of the baffle 6 are fixedly connected, and the side wall of the baffle 6 close to the side plate 21 is fixedly installed with a plurality of scanners 8 along the vertical height. 23. A lifting device is fixedly installed in the groove one 23, a connecting block 19 is fixedly installed on the side wall of the lifting device, and a second groove 42 is opened on the side wall of the connecting block 19 away from the side plate 21. Angle adjustment device, the angle adjustment device is sleeved with a convex block 41, the side wall of the convex block 41 away from the groove is fixedly installed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com