Solar self-cleaning device based on solar sewage treatment

A technology for solar energy device and sewage treatment, which is applied to the feeding/discharging device, circuit device, battery circuit device, etc. of the sedimentation tank, which can solve the problems of high cleaning risk, manpower and material resources, and time-consuming, etc. The effect of simplifying the operation steps, ensuring physical health, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

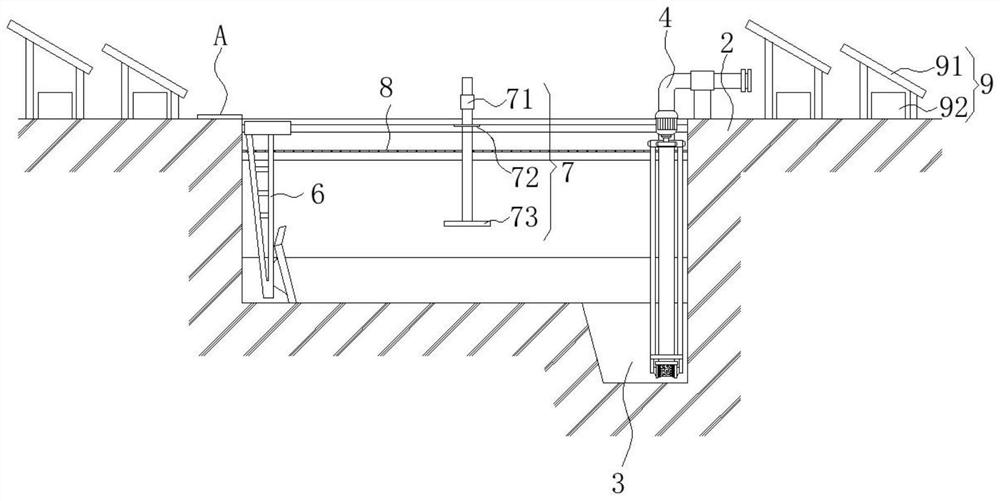

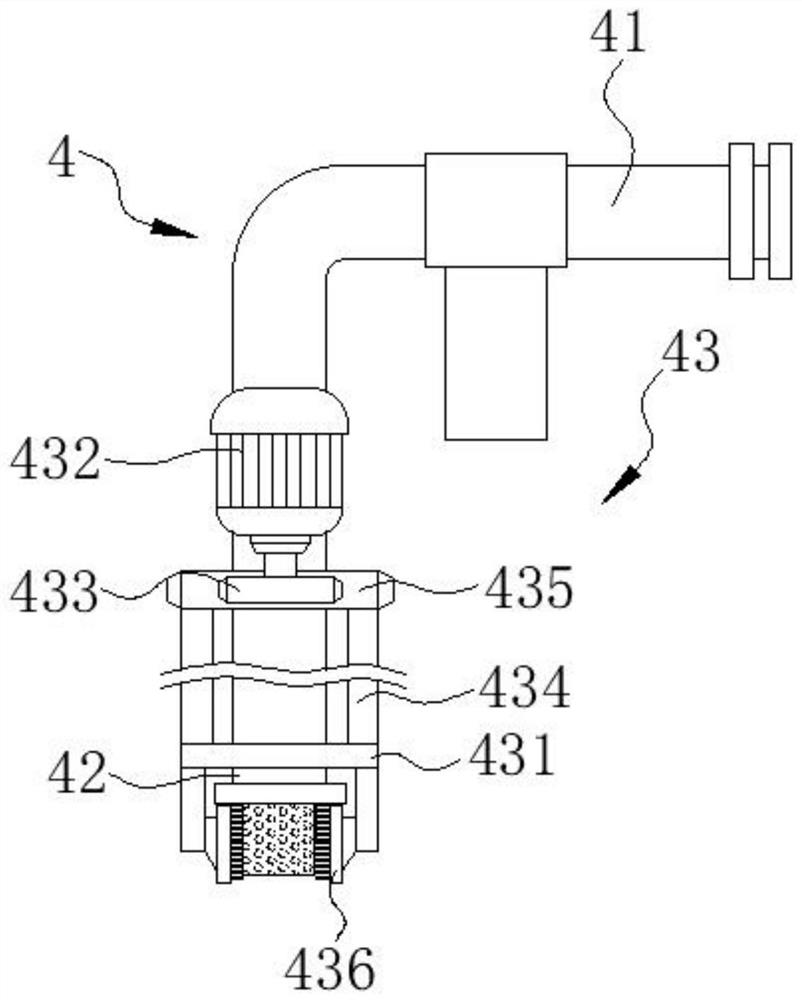

[0036] Embodiment one: if figure 1 , 3, 4, and 5, the present invention provides a technical solution: a solar self-cleaning device based on solar sewage treatment, including a sewage pool 1, a ground surface 2, and a downward depression is set on one side bottom wall of the sewage pool 1 The silt discharge tank 3, the top of the silt discharge tank 3 and the ground of the sewage tank 1 form a chamfered side surface as an inclined surface, and the angle between it and the horizontal plane is 60 to 70 degrees, and the inclined surface can help guide the silt when it falls , adopting a shape with a large top and a small bottom can help the silt accumulated in the silt discharge tank 3 to be sucked more intensively. Sewage parts 4 are arranged between the top, and sewage parts 4 include mud suction pipe 41, the mud suction pump 42 that is located at the bottom of mud suction pipe 41, and the upper end of mud suction pipe 41 is set as ninety degree bending, and outlet end is hori...

Embodiment 2

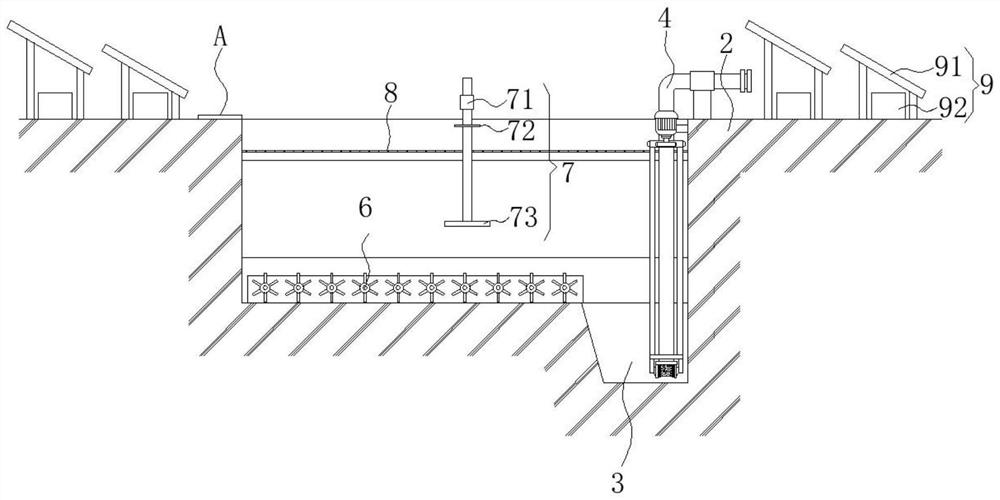

[0038] Embodiment two: if figure 2 , 6 As shown, the present invention provides a kind of technical scheme: the mud cleaning part 6 comprises the sealing cover 6A that is positioned at the inner wall of both sides of the sewage tank 1, and there are a plurality of dredging impellers 6B with equal intervals rotating between the side walls of the two sealing covers 6A. The number of blades of a dredging impeller 6B is six, and the outer extension end of the blade is set as a thick rubber layer of one centimeter, and the ground of the sewage pool 1 is not blocked when the bottom is rotated. In addition, two adjacent dredging impellers 6B The blades do not touch when rotating, and the two ends of the dredging impeller 6B extend into the sealing cover 6A and are sleeved with a sprocket 6C. The multiple sprockets 6C are driven by a drive motor through chain transmission, and the dredging impeller 6B is in operation. Rotate and stir the silt to make the silt flow towards the silt d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com