Multi-polarization industrial distillation tower

A technology of distillation column and chemical industry, applied in the field of distillation column, can solve the problems such as the decline of fine quality of separation and distillation of distillation column, low cleaning convenience of multi-stage baffles, waste of water resources, etc., so as to improve cleaning convenience and improve gas-liquid separation. Distillation of fine quality, the effect of saving water use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

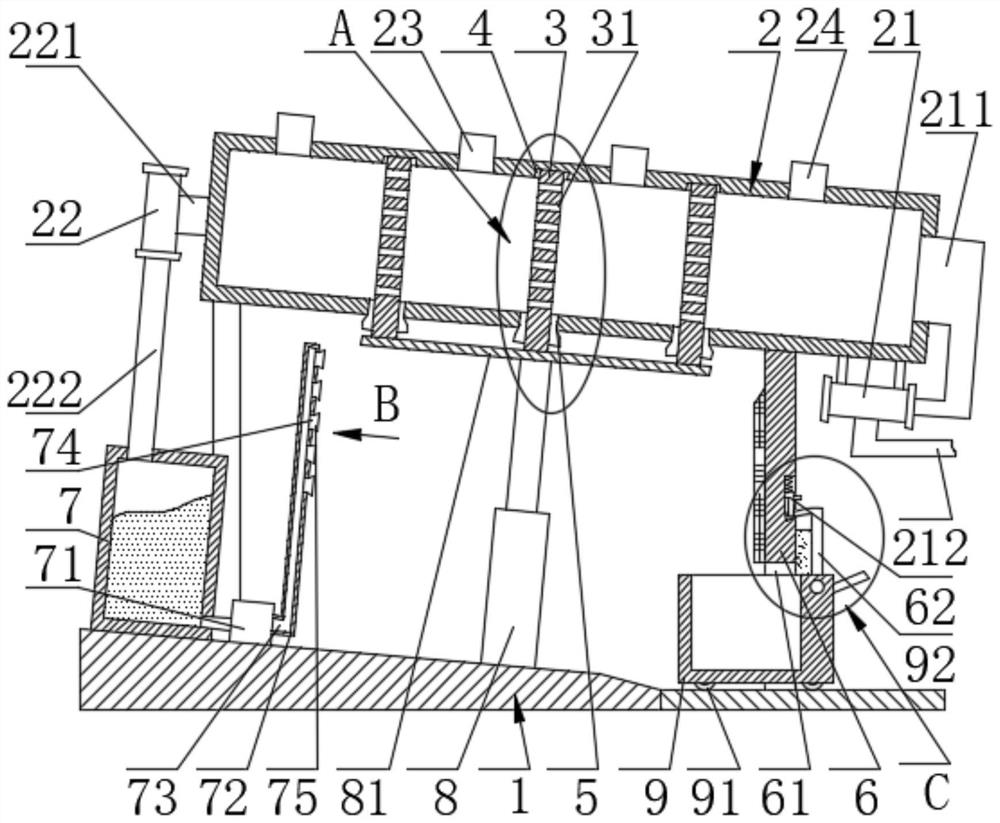

[0026] see figure 1 , a kind of multipolar chemical distillation tower in the figure, comprises tower body 2, and is arranged on the outrigger plate 6 on the fixed surface 1, the upper end of the outrigger plate 6 is fixedly welded with the tower body 2, and the tower body 2 is equipped with the The boiler 21, the condenser 22, the upper right end of the tower body 2 is provided with a feeding pipe 24, the reboiler 21 is provided with a heating pipe 211 and a drain pipe 212, the heating pipe 211 is connected with the bottom of the right end of the tower body 2, and the tower body 2 is interposed with a multi-level partition 3.

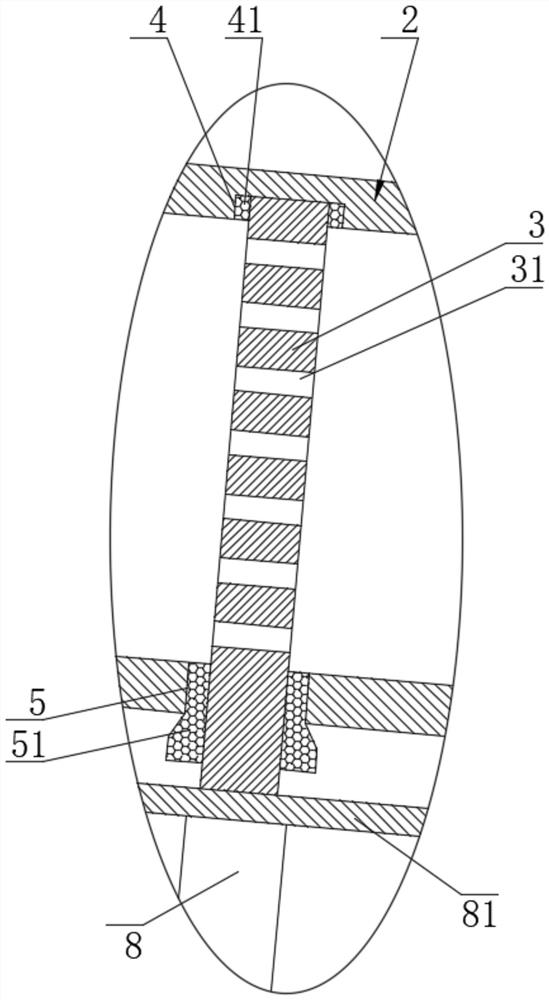

[0027] The top of the tower body 2 is laterally provided with a multi-stage exhaust pipe 23, and the side plate of the tower body 2 is provided with a slot 4 and a mounting hole 5. The slot 4 is bonded with a sealing layer 41, and the mounting hole 5 is bonded with a The sealing sleeve 51, the multi-stage partitions 3 pass through the sealing sleeve ...

Embodiment 2

[0030] see figure 1 , figure 2 , image 3 , this embodiment is further described for Example 1, a multi-polar chemical distillation tower in the illustration, including the tower body 2, and the leg plate 6 arranged on the fixed surface 1, the upper end of the leg plate 6 and the tower body 2 Fixed installation, tower body 2 is provided with reboiler 21, condenser 22, the upper right end of tower body 2 is provided with feeding pipe 24, reboiler 21 is provided with heating pipe 211, drain pipe 212, heating pipe 211 It is connected with the bottom of the right end of the tower body 2, and the tower body 2 is inserted with a multi-stage partition plate 3.

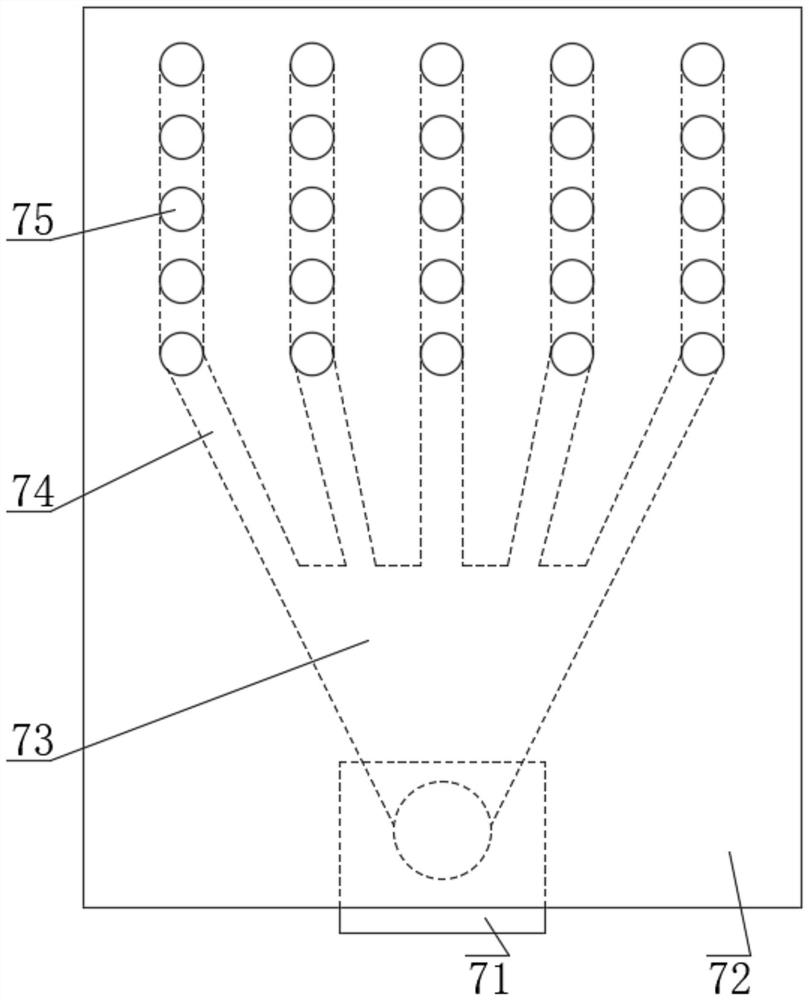

[0031] The fixed surface 1 is provided with a water tank 7, a water pump 71, and a cylinder 8. The condenser 22 is provided with an air pipe 221 and a circulating liquid pipe 222. The gas pipe 221 is communicated with the top left side of the tower body 2, and the circulating liquid pipe 222 is communicated with the water...

Embodiment 3

[0036] see figure 1 , Figure 4 , Figure 5 , this embodiment is further described for other examples, a multi-polar chemical distillation tower in the figure includes a tower body 2, and a leg plate 6 arranged on the fixed surface 1, and the upper end of the leg plate 6 is connected to the tower body. 2. Fixed installation, tower body 2 is provided with reboiler 21, condenser 22, the upper right end of tower body 2 is provided with feeding pipe 24, reboiler 21 is provided with heating pipe 211, drain pipe 212, heating pipe 211 It is connected with the bottom of the right end of the tower body 2, and the tower body 2 is inserted with a multi-stage partition plate 3.

[0037] The outrigger plate 6 is provided with a square opening 61, a chute 63, and an arc-shaped slot 65. A positioning block 62 is slidably clamped in the chute 63, and a spring 64 is welded between the positioning block 62 and the inner wall of the chute 63. The fixed surface 1 There is a slag storage truck ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com