Quick aligning device for wood splicing

A wood and fast technology, which is applied in the direction of wood processing appliances, wooden veneer joints, manufacturing tools, etc., can solve the problem of unusable wood and achieve the effect of reducing the time required for wood splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

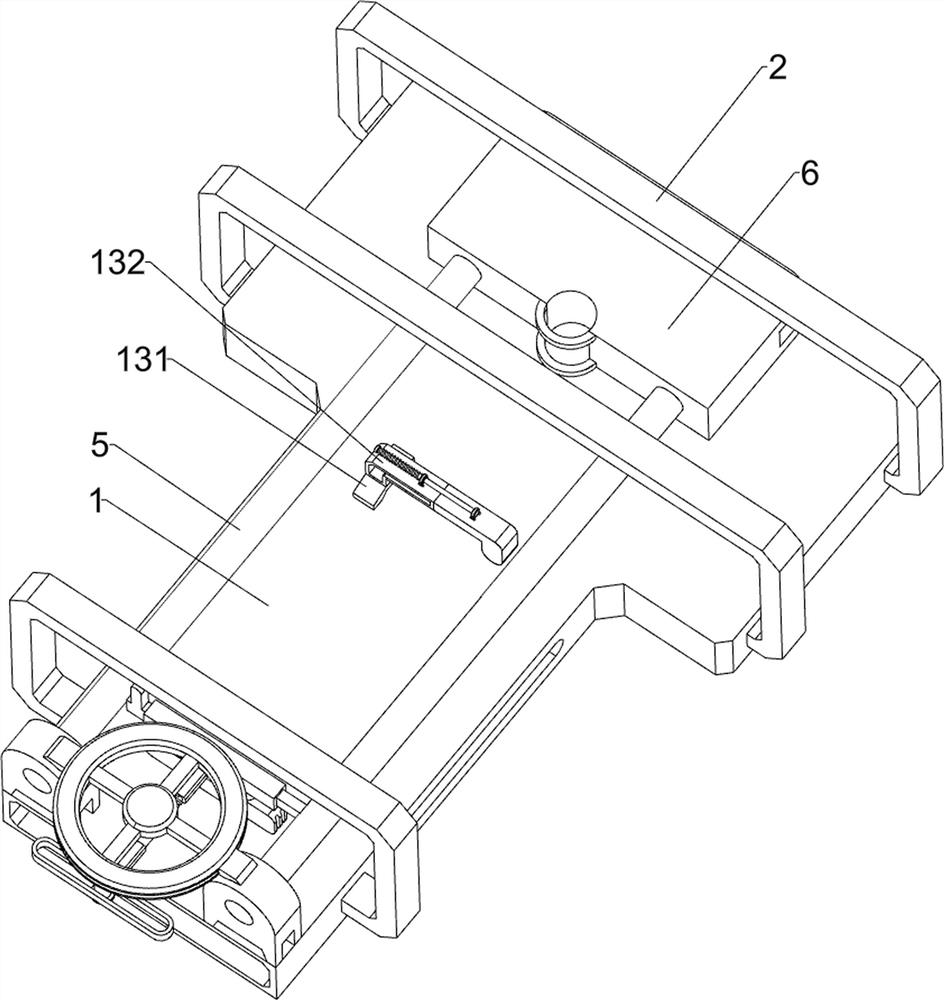

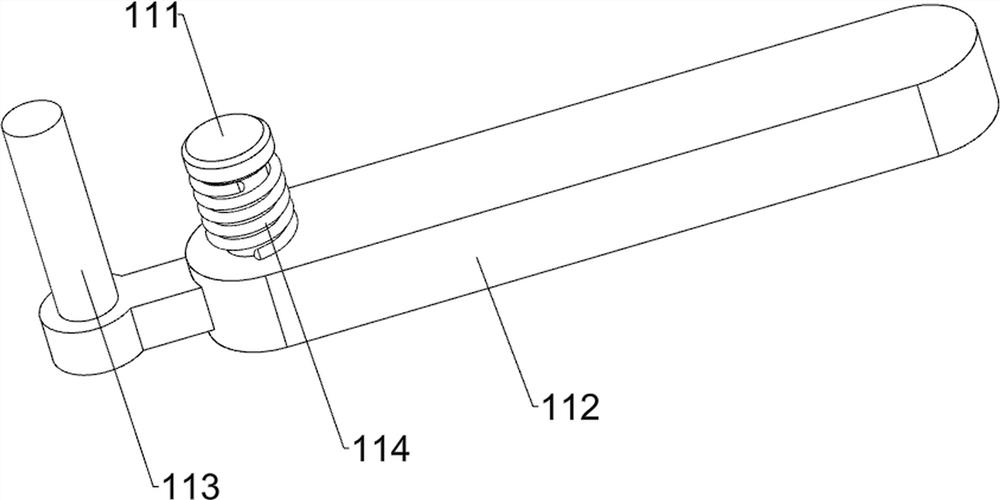

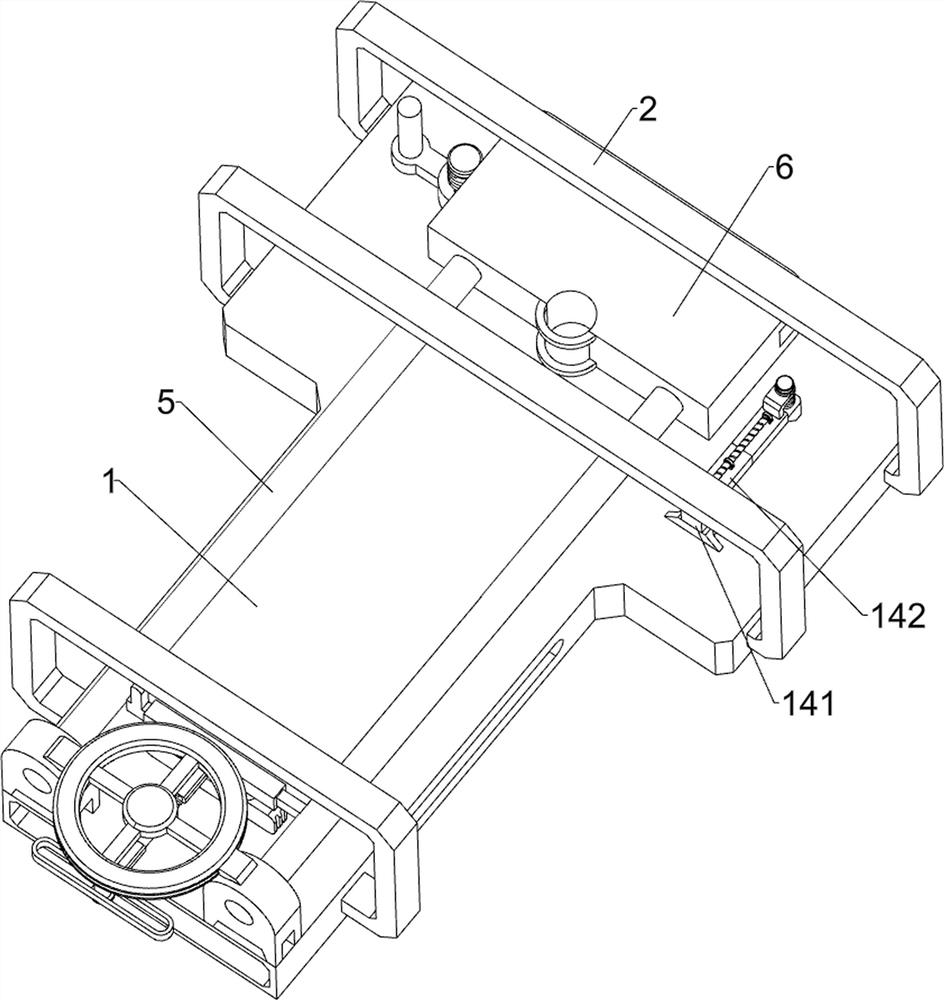

A quick alignment device for wood splicing, refer to Figure 1-Figure 3 As shown, it includes a base plate 1, a first mounting frame 2, a mounting block 3, a second mounting frame 4, a mounting rod 5, a positioning plate 6, a driving wheel 71, a first sliding sleeve 72, a driving rod 73, a guide rod 74, The first push plate 75 , the first compression spring 76 , the alignment mechanism 11 , the limit mechanism 12 , the guide mechanism 13 and the correction mechanism 14 . A mounting block 3 is welded, a second mounting frame 4 is welded on the left side of the bottom plate 1, a mounting rod 5 is welded on the mounting block 3, and a positioning plate 6 is fixed between the right ends of the mounting rod 5, and the positioning plate 6 can place the wood. The upper side of the mounting block 3 is rotatably connected with a driving wheel 71, the left side of the positioning plate 6 is provided with positioning holes symmetrically up and down, and the left side of the front mounting...

Embodiment 2

On the basis of Example 1, refer to figure 1 , Figure 12 and Figure 13 As shown, it also includes a fixing mechanism 15, which can place the connector. The fixing mechanism 15 includes a mounting sleeve 151, a blanking frame 152, a fourth compression spring 153, a second push plate 154, a connecting plate 155, The second guide rod 156 , the fifth compression spring 157 and the baffle plate 158 are all welded with a mounting sleeve 151 in the middle of the mounting rod 5 , and a blanking frame 152 is welded between the mounting sleeves 151 , and the blanking frame 152 can place the connecting device. A second push plate 154 is slidably arranged on the right side of the blanking frame 152, a fourth compression spring 153 is connected between the left side of the second push plate 154 and the left side of the blanking frame 152, and a fourth compression spring 153 is welded on the right side of the blanking frame 152. The connecting plate 155, the right side of the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com