Special welding frame for bottom of large boiler

A large-scale boiler and welding frame technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing welding difficulty and affecting the welding quality of workers' boilers, and achieve the goal of increasing welding difficulty and improving welding range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the technical means, creative features, achieved goals and effects of the present invention easy to understand and understand, the present invention is further described below with reference to the accompanying drawings and embodiments.

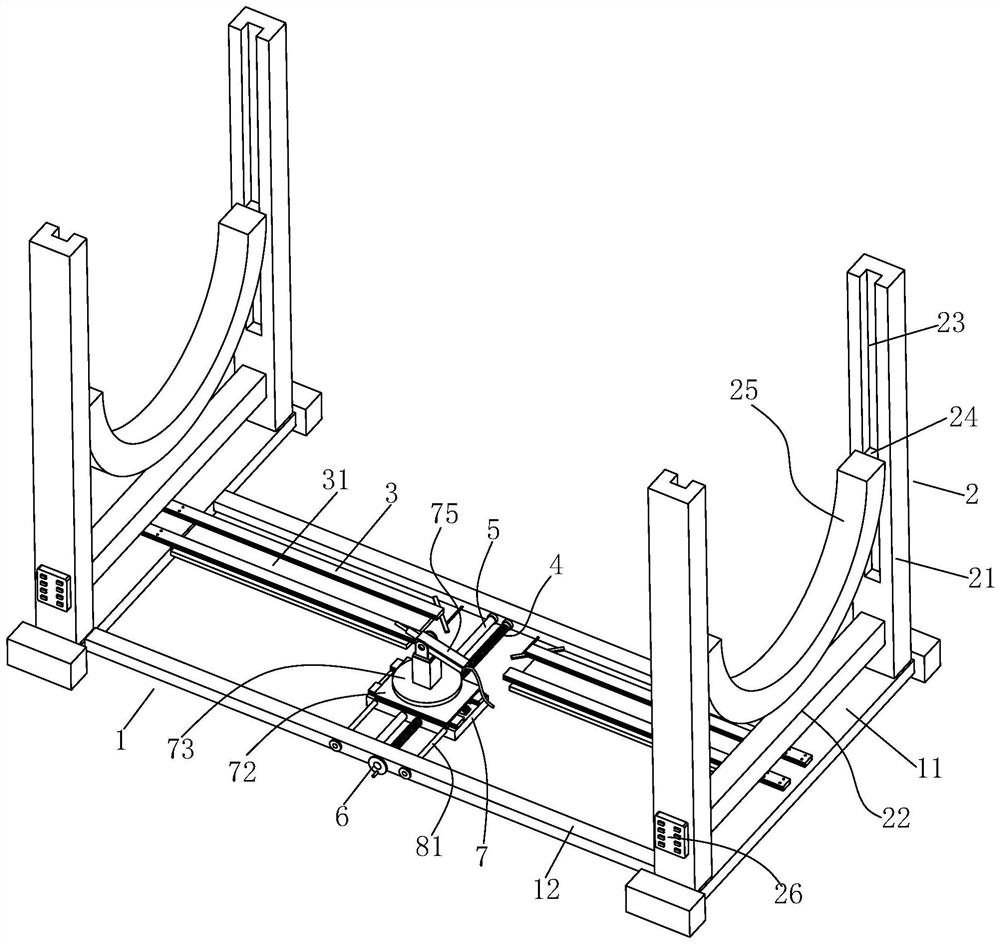

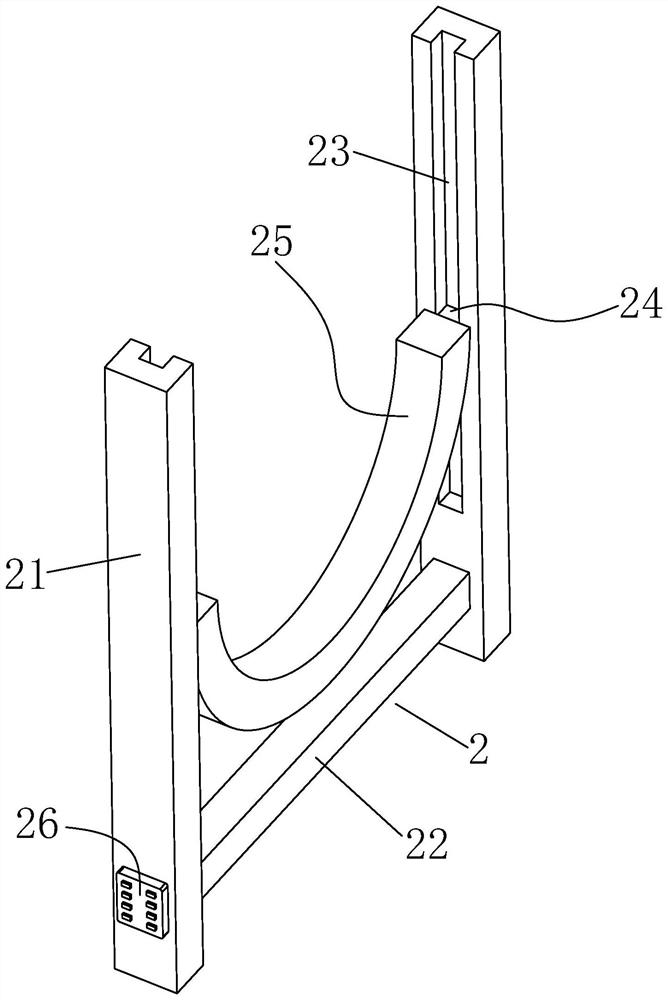

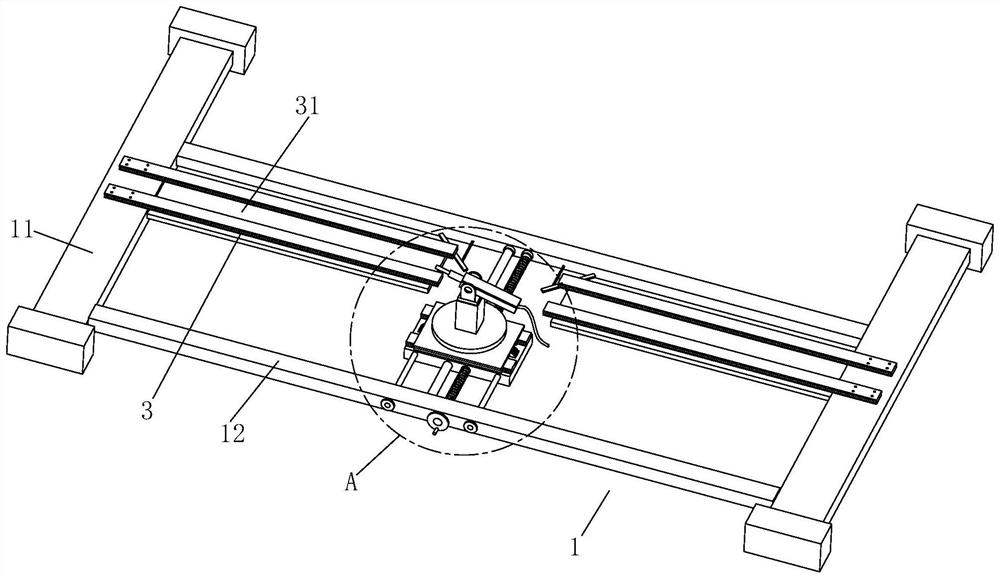

[0037] like figure 1 and figure 2 As shown, the special welding frame for the bottom of the large boiler includes a base frame 1 and two frame bodies 2 welded and fixed on the base frame 1. The two frame bodies 2 are symmetrically distributed on the left and right, and each frame body 2 is composed of two longitudinally distributed frames. Each frame column 21 and the connecting plate 22 connecting the two frame columns 21 are formed. The two frame columns 21 of each frame body 2 are symmetrically provided with two electric sliding rails 23 on the inner frame column wall. The electric sliding rails 23 An electric sliding block 24 is correspondingly arranged inside, and a bearing bracket 25 for supporting the boiler i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap