Flexible welding production line for small and medium-sized parts of railway wagon

A welding production line, railway freight car technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low efficiency and low degree of welding automation, achieve stable and reliable grasping, improve welding efficiency and welding Coverage, the effect of ensuring welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution in a typical embodiment of the present invention will be clearly and completely described below with reference to the drawings in the embodiments of the present invention.

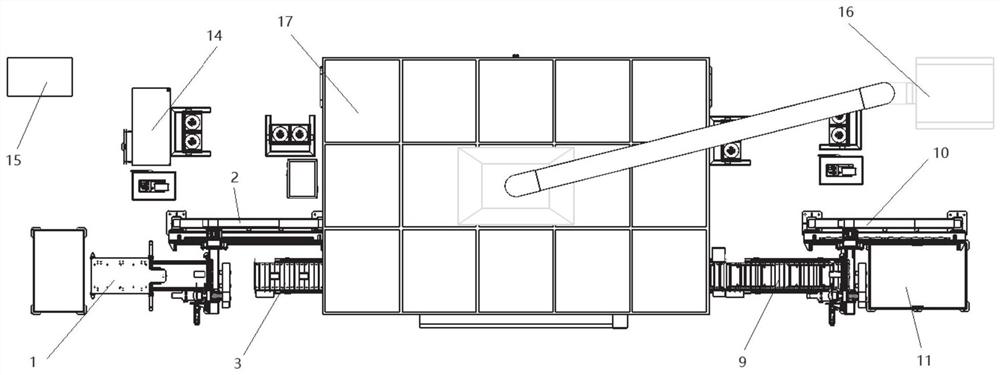

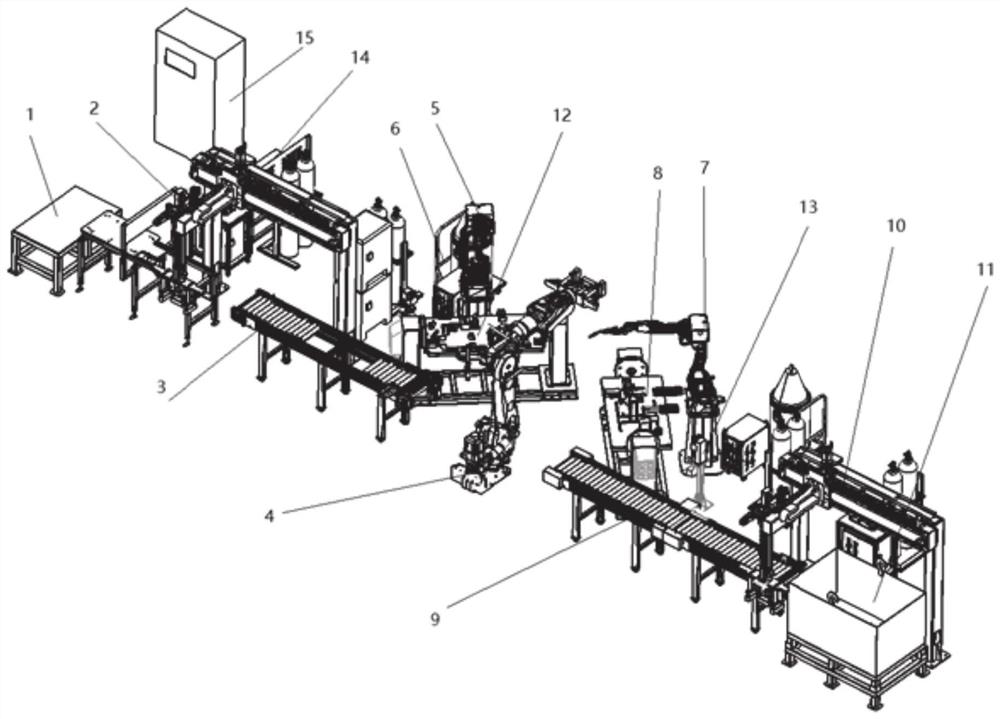

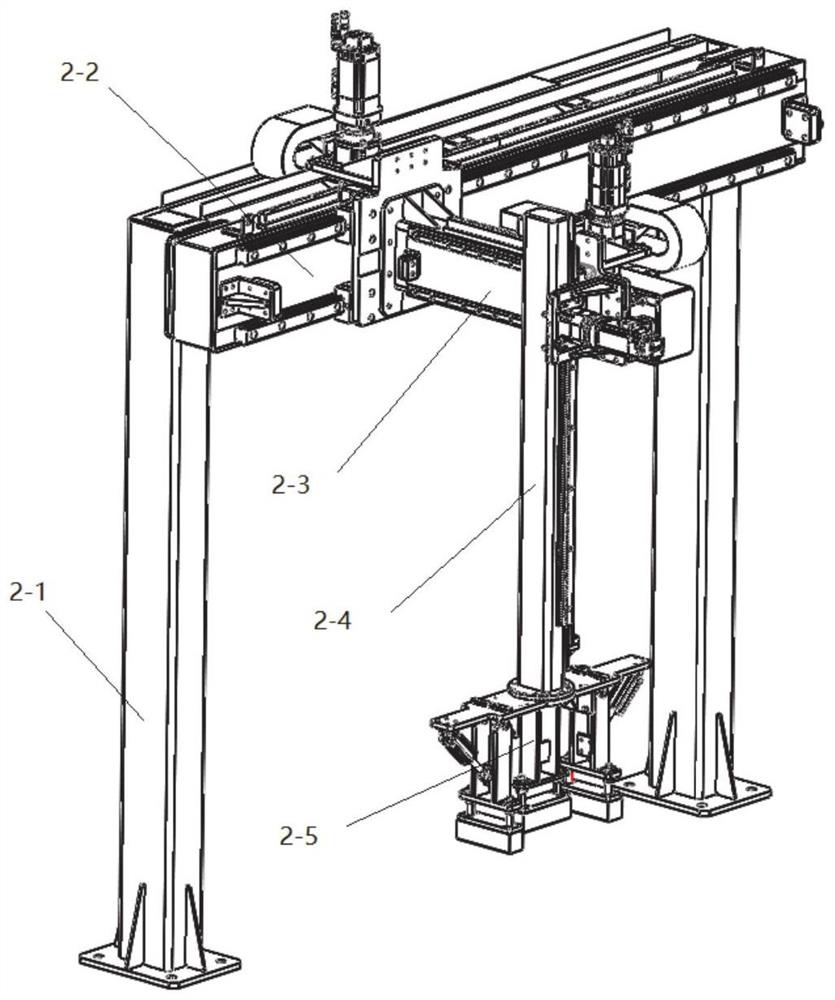

[0041] Such as figure 1 , figure 2 As shown, the present embodiment provides a flexible welding production line for small and medium parts of railway wagons, including a spot welding platform 1, a first handling device 2, a feeding conveying device 3, a second handling device 4, a feeding conveying device 9 and at least one Flexible welding device;

[0042] The flexible welding device includes a displacement device and an automatic welding device. The displacement device has a swingable fixed plate 6-4 and a plurality of welding stations arranged on the fixed plate 6-4. Positioning device for small and medium parts;

[0043]Spot welding platform 1 spot welding group for small and medium parts to be welded, the first handling device 2 grabs the small and medium parts to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com