A welding equipment suitable for valve manufacturing

A technology of welding equipment and valves, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large welding limitations, welding virtual welding, and increased defective rate, and achieve simple and stable structure, improve Effect of service life and reduction of defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

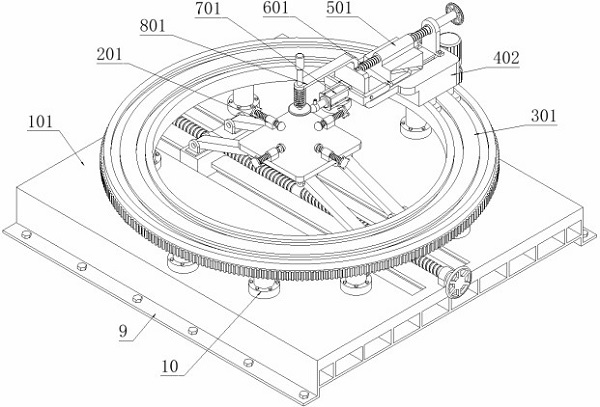

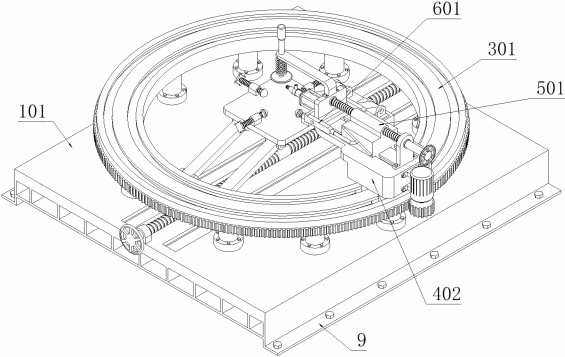

[0044] as attached figure 1 to attach Figure 17 Shown:

[0045] The present invention provides a kind of welding equipment suitable for the production and manufacture of valves, which includes a supporting device 1; two first mounting plates 9 are fixedly connected to the bottom of the supporting device 1, ten supporting columns 10 are installed on the supporting device 1, and ten supporting A running track part 3 is fixedly connected to the column 10; four positioning devices 2 are fixedly connected to the support device 1, and the structures on the four positioning devices 2 are the same; a driving device 4 is installed on the running track part 3, and the driving device 4 An adjustment part 5 is installed on it; an upper mold positioning device 8 is installed on the driving device 4; a welding support part 6 is rotatably connected to the driving device 4; a welding part 7 is installed on the welding support part 6.

[0046] as attached Figure 4 , Figure 5 , Figure ...

Embodiment 2

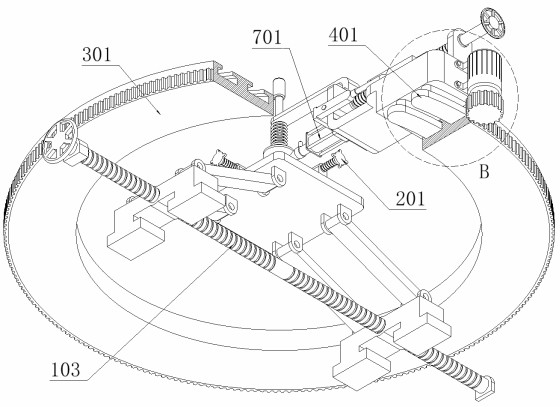

[0049] as attached Figure 6 As shown, the positioning device 2 includes: a positioning support block 201, four positioning support blocks 201 are provided, and the four positioning support blocks 201 are fixedly connected to the second mounting plate 105 respectively; Threaded hole; Positioning propulsion shaft 202, positioning propulsion shaft 202 is provided with four, and four positioning propulsion shafts 202 are respectively threaded on four positioning support blocks 201; Positioning propulsion shaft 202 front end is spherical structure; Positioning device 2 is provided The propulsion can be realized by rotating and positioning the propulsion shaft 202, and the structure is simple and stable. At the same time, the multi-directional positioning of the valve assembly can be realized by setting four positioning propulsion shafts 202 to thread on the positioning support block 201 respectively. Adjusting the four positioning propulsion shafts 202 can realize the adjustment o...

Embodiment 3

[0052] as attached Figure 5As shown: on the basis of the first embodiment, this embodiment provides another lifting and driving structure of the second mounting plate 105, which solves the need to manually rotate the two-way screw 103 during the actual lifting operation of the second mounting plate 105 To drive, the problem of slow lifting speed, the support device 1 includes: a support base plate 101, the support base plate 101 is fixedly connected on the two first mounting plates 9; the support base plate 101 is provided with two slide grooves; the lifting drive block 102, Two lifting drive blocks 102 are provided with two, and the two lifting drive blocks 102 are all slidably connected in two chutes on the support base plate 101; the two lifting drive blocks 102 are all provided with threaded holes; the two-way screw rod 103, the two-way screw The rod 103 is connected to the support base plate 101 through the support rotating shaft; the two-way screw rod 103 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com