Welding tool for butting of cylinder bodies

A technology for welding tooling and cylinders, applied in welding accessories, welding equipment, auxiliary welding equipment, etc., can solve problems such as inability to clamp cylinders, inability to flip two cylinders, and no infrared sensor, etc., to achieve expanded welding range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

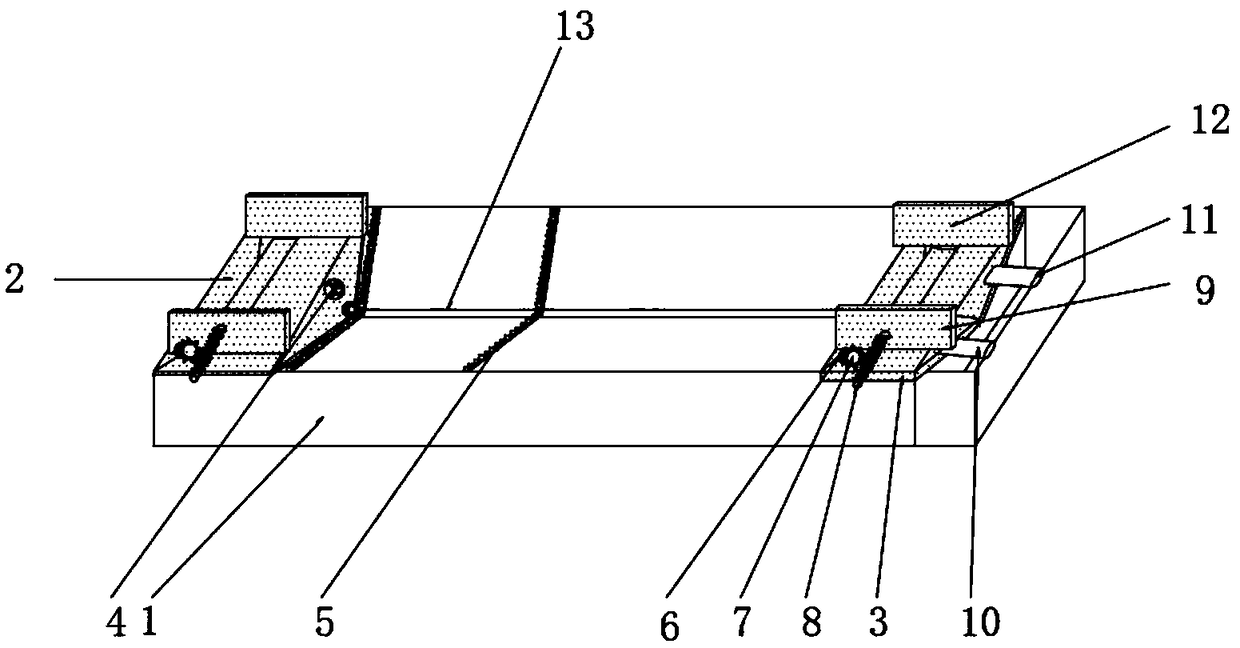

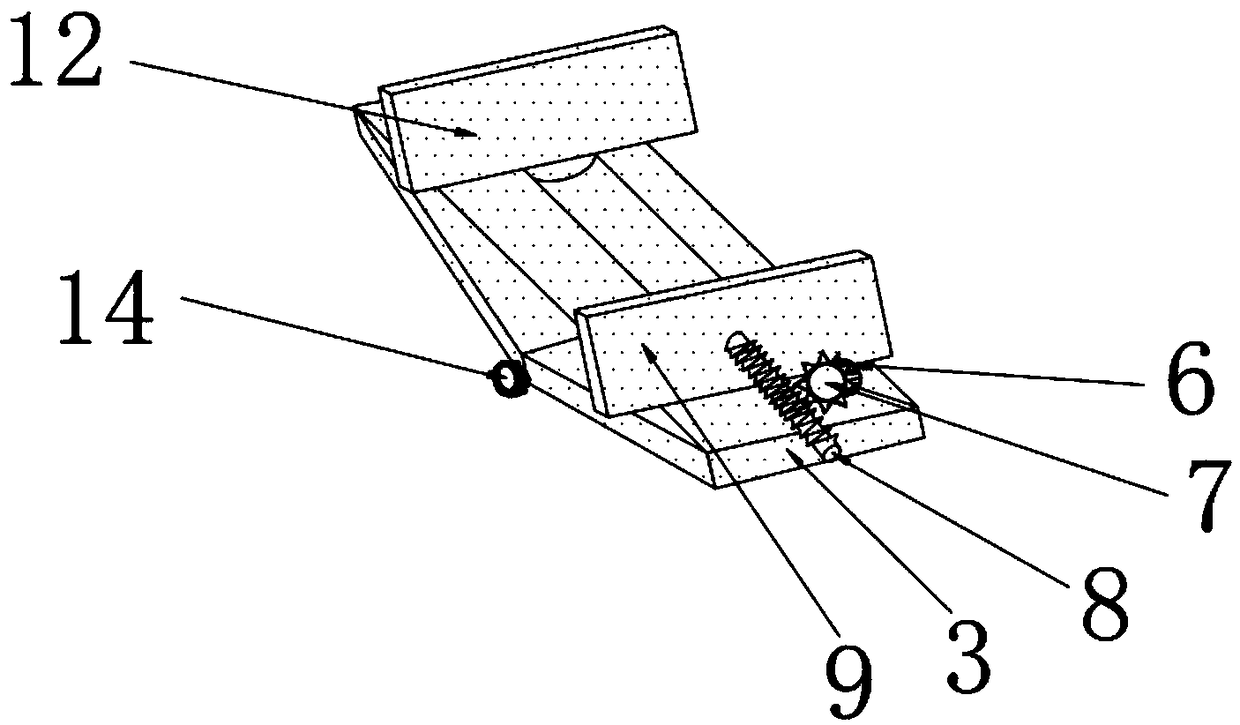

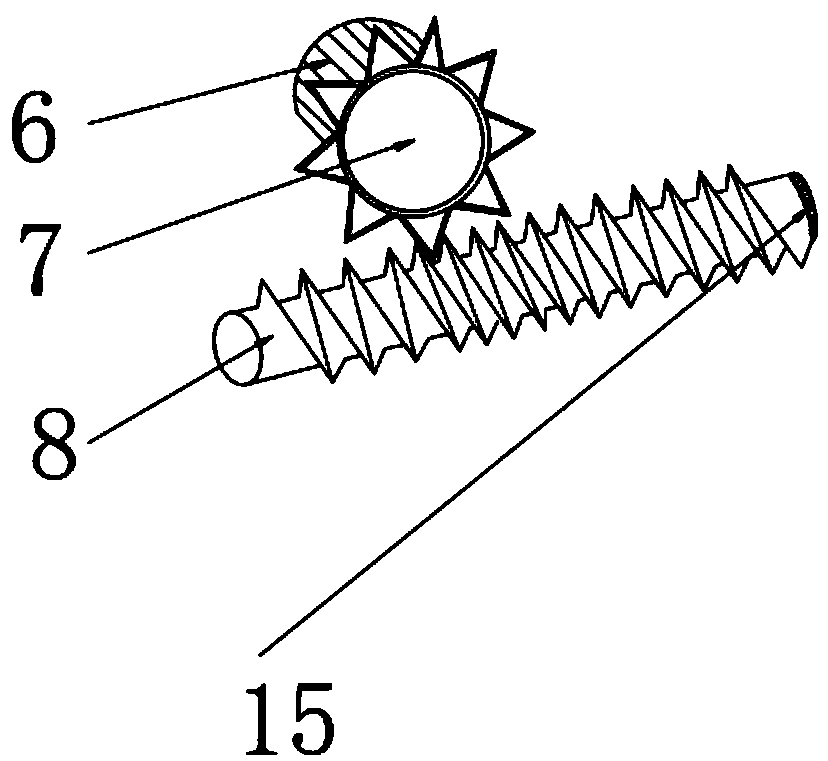

[0023] Example: refer to Figure 1-3 , the present invention provides a technical solution, a welding tool for cylinder butt joint, including a tooling seat 1, one side of the tooling seat 1 is fixedly connected with a fixed fixture 2, and the other side of the tooling seat 1 is provided with a movable fixture 3. A stepping motor linear guide slide 13 is embedded at the bottom side of the tooling seat 1 close to the fixing fixture 2, and the upper end of the stepping motor linear guide slide 13 is fixedly connected with a rack 5, and the fixing fixture 2 The side wall is embedded with a stress sensor 4, one side of the movable fixture 3 is fixedly connected with a first hydraulic rod 10, and the upper end of the movable fixture 3 is fixedly connected with a fixed clamp block 12, and one side of the bottom end of the movable fixture 3 is rotatably connected with a first hydraulic rod 10. Two transmission gears 14, one side of the first hydraulic rod 10 is provided with the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com