Production device of double-layer wire

A production device and wire technology, applied in the field of wires, can solve the problems of poor integration of assembly and transfer, low integration of double-layer processing, and low integration of wiring, etc., to achieve high processing efficiency, good shaping effect, stable and efficient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

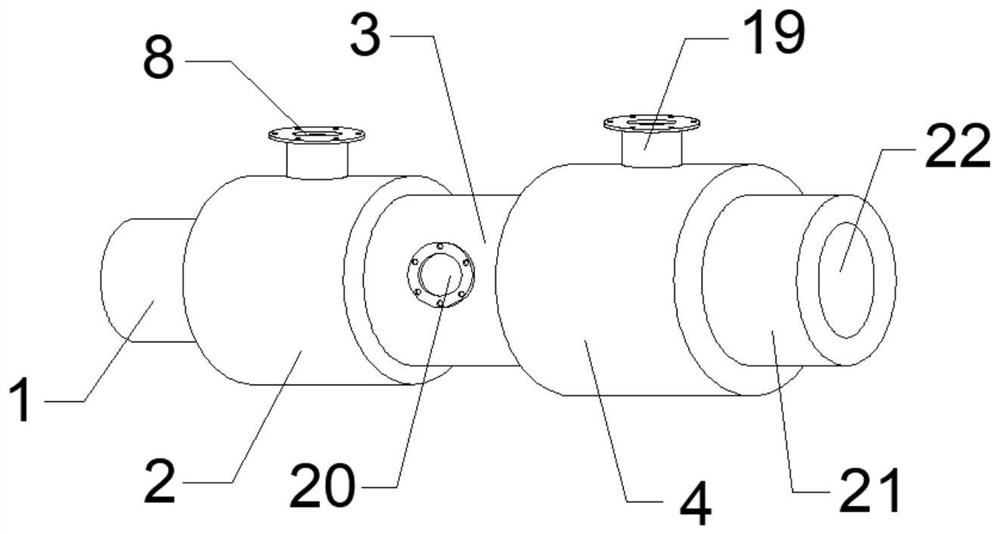

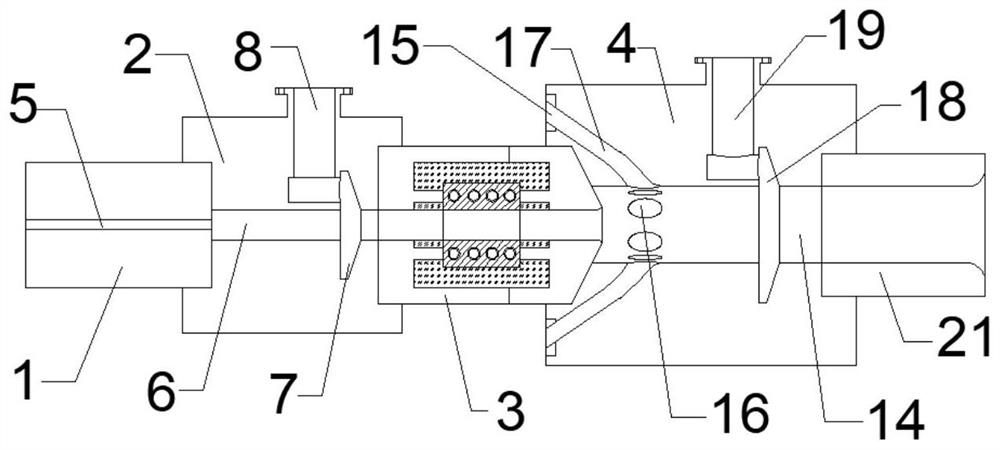

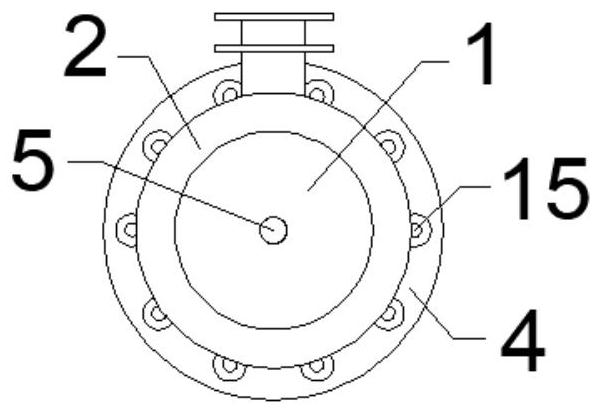

[0022] like Figure 1-4 As shown in the figure, a production device for a double-layer electric wire includes an inner conductor sleeve 1, a first plastic-covered sleeve 2 and a second plastic-covered sleeve 4, and also includes a cooling jacket 3, an inner copper sleeve 9 and a spiral copper tube 10, One end of the inner-layer wire sleeve 1 is covered with a first plastic wrapping sleeve 2 , a discharge end of the first plastic wrapping sleeve 2 is inserted with a cooling jacket 3 , and one end of the cooling sleeve 3 is sleeved with a second wrapping sleeve 2 . The plastic sleeve 4, the discharge end of the second plastic-covered sleeve 4 is inserted with a two-layer wire sleeve 21, the inner-layer wire sleeve 1 is provided with an inner-layer wire entry channel 5, and the first plastic-covered sleeve 2 is provided with a first overmolding channel 6, the second overmolding sleeve 4 is provided with a second overmolding channel 14, and one end of the second overmolding channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com