A high and low speed compression damping adjustable valve train assembly structure

An assembly structure, high and low speed technology, applied in the direction of spring/shock absorber, shock absorber, shock absorber-spring combination, etc. The performance of the vibrator cannot be dealt with accordingly, so as to avoid leakage, reduce the damping force, and enhance the damping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

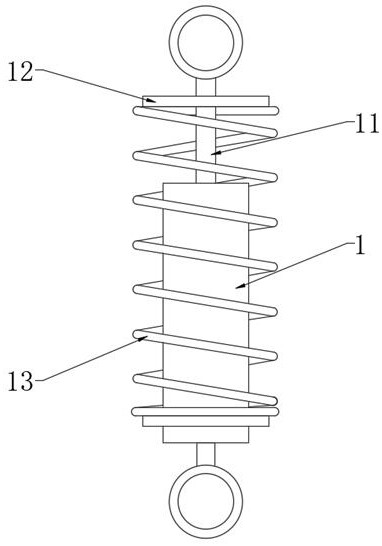

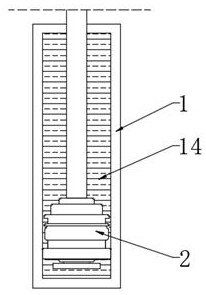

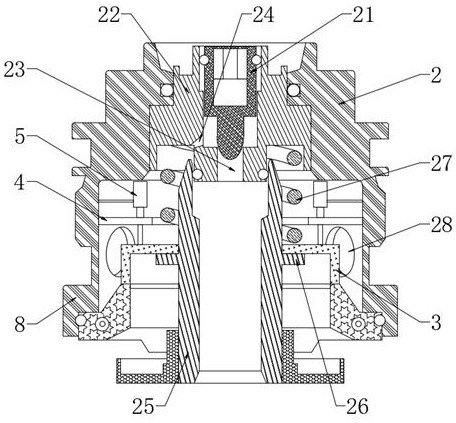

[0040] see Figure 1-6, a high and low speed compression damping adjustable valve train assembly structure, including a shock absorber body 1, a guide rod 11 is inserted on the shock absorber body 1, and a spring is fixedly connected to the shock absorber body 1 and the guide rod 11 Plate 12, a spring 13 is fixedly connected between the two spring plates 12, a casing 2 is threadedly connected to the lower end of the guide rod 11, the damper body 1 is filled with oil 14, and the upper end of the casing 2 is threadedly connected with an adjusting wheel 22, The adjusting wheel 22 is threadedly connected with an adjusting core 21, the lower end of the adjusting wheel 22 is drilled with an oil flow channel 23, the adjusting core 21 is in contact with the oil flow channel 23, a flow limiting hole 24 is drilled on the adjusting wheel 22, and the lower end of the adjusting wheel 22 is inserted with a The oil inlet cylinder 25 is fixedly connected with a fixed ring plate 26. The oil in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com