Efficient elevator guide rail installation precision calibration equipment

A technology for elevator guide rails and installation accuracy, used in measuring devices, mapping and navigation, measuring inclination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

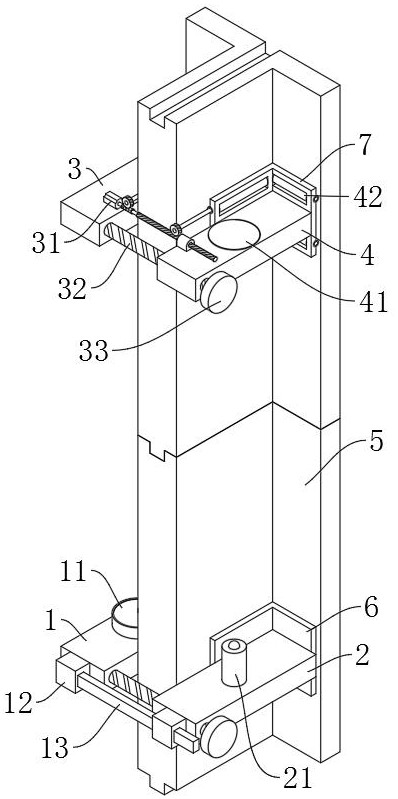

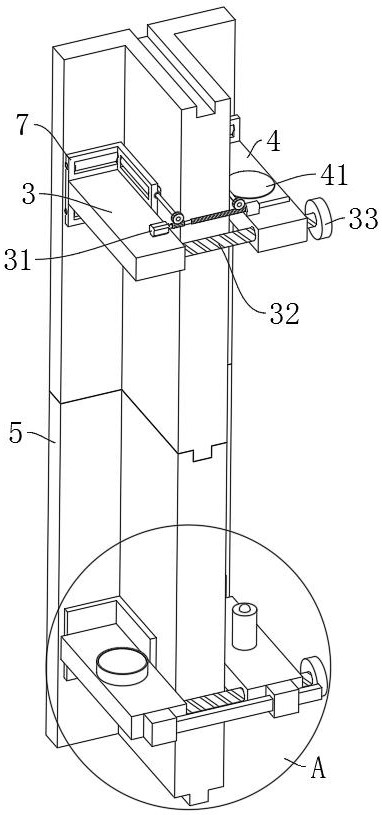

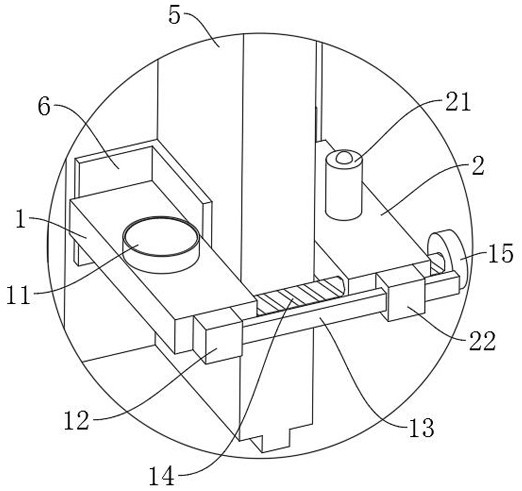

[0029] The present invention calibrates the guide rail body 5 by fixing and locking the first lower support plate 1 and the second lower support plate 2 on the bottom guide rail body 5, so that it is in a vertical state in the elevator shaft, and then the first upper The support plate 3 and the second upper support plate 4 are limited and clamped above the first lower support plate 1 and the second lower support plate 2 and calibrated, and the first upper support plate 3 and the second upper support plate 4 are aligned along the guide rail body 5 Move upwards, by monitoring the display point of the laser emitted by the laser emitter 21 on the light display panel 43 to judge whether the other guide rail bodies 5 connected based on the bottom guide rail body 5 have problems of inclination and misalignment, and adjust them in time Calibration, the error of this calibration method is small, especially suitable for the calibration of high-height elevator guide rails, and it is not e...

Embodiment 2

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com