Rocker arm assembly

A technology of rocker arm components and components, applied in the direction of engine components, valve devices, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

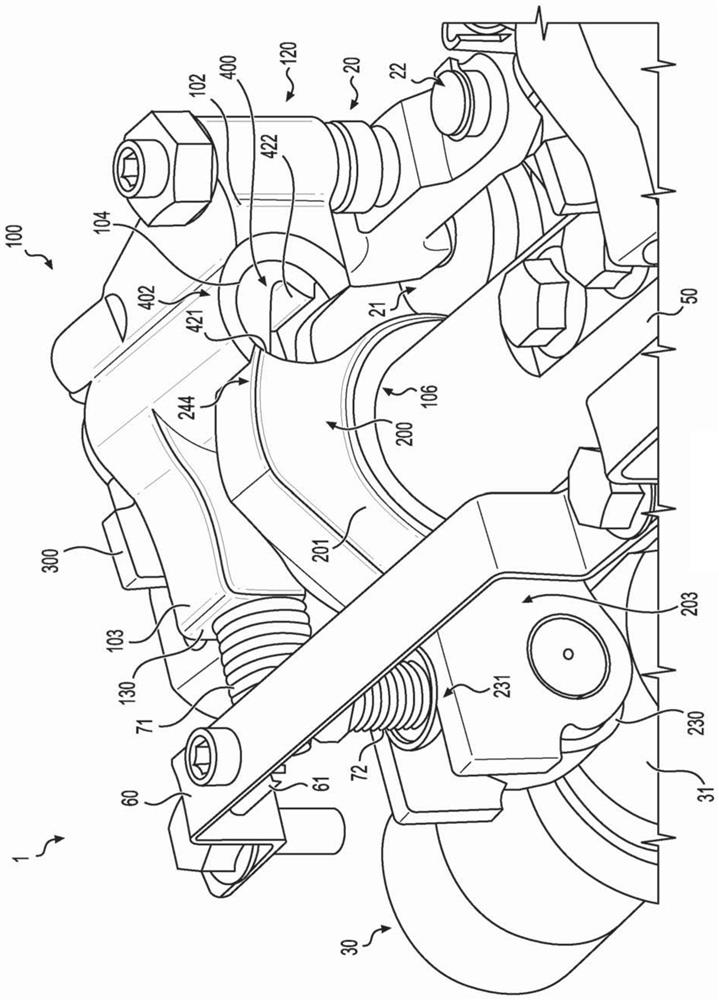

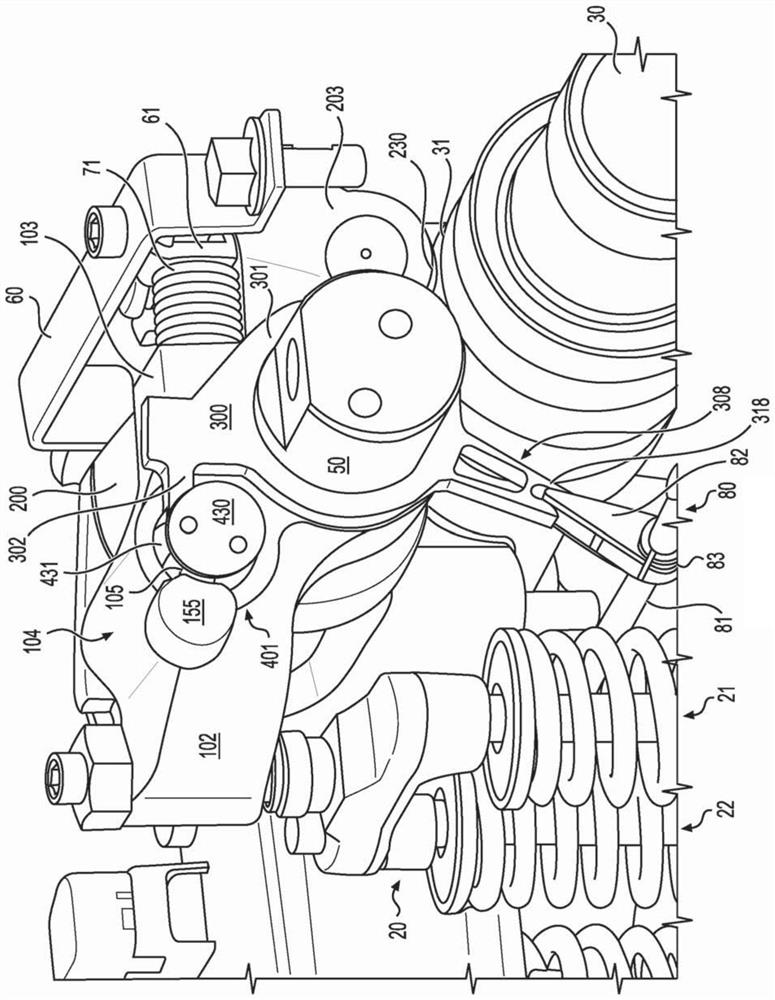

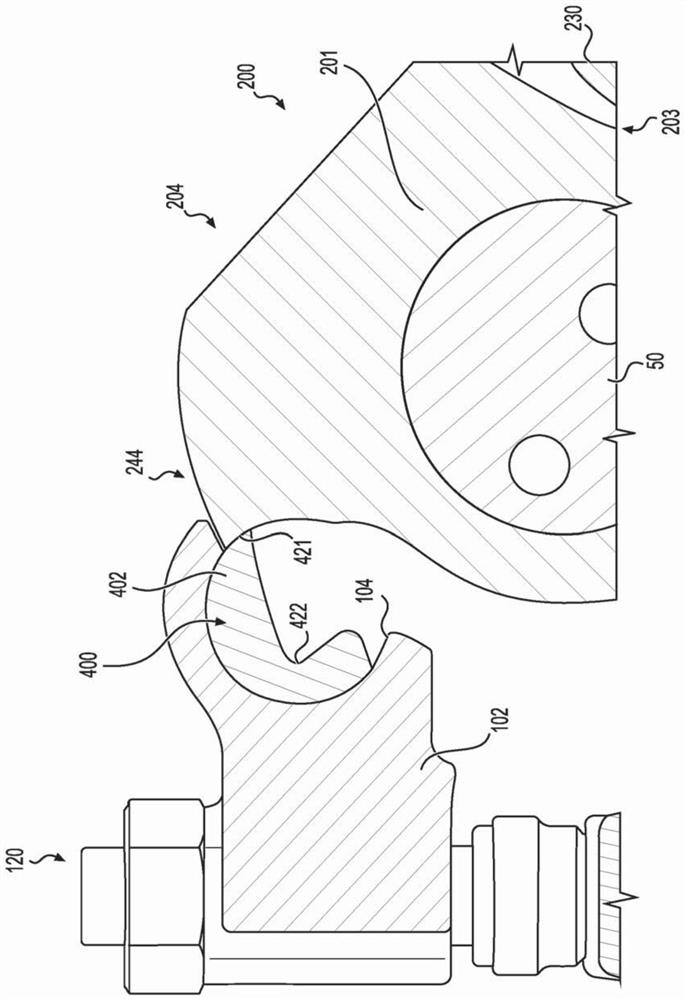

[0016] Reference will now be made in detail to the illustrated examples in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

[0017] The rocker arm assemblies 1 , 2 may include a main rocker arm 100 . The main rocker arm 100 may include a body 101 configured to be rotatable about the rocker arm axis 50, such as through a central hole through the body. The valve end 102 extends from the body 101 . The valve end 102 can be actuated against a valve or valve bridge. An optional valve end capsule assembly 120 can be installed in the valve end and can include any number of variable valve actuation or lash adjustment features, such as castellated capsules, lost motion capsules, hydraulic or mechanical lash adjusters, and others valve actuation assembly. The valve end 102 is configured to act on the valve assembly 20 . In the example, two valves 21 , 22 are shown connected to a valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com