Quickly-installed lifeline device

A lifeline and fast technology, applied in the processing of building materials, construction, building construction, etc., can solve the problems of time-consuming, labor-intensive, labor-intensive and material-intensive protection, and achieve the effect of easy protection, ensuring safety performance, and improving energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help the understanding of the present invention, but do not constitute a limitation of the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not conflict with each other.

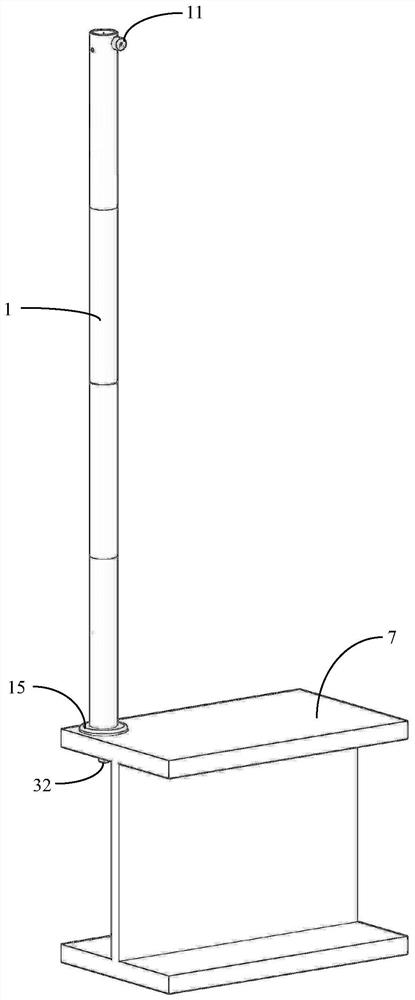

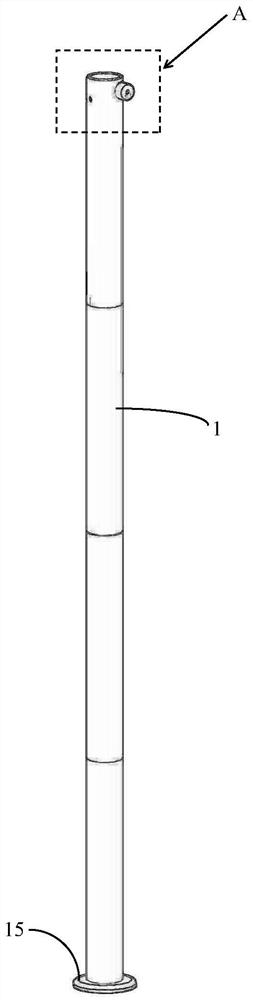

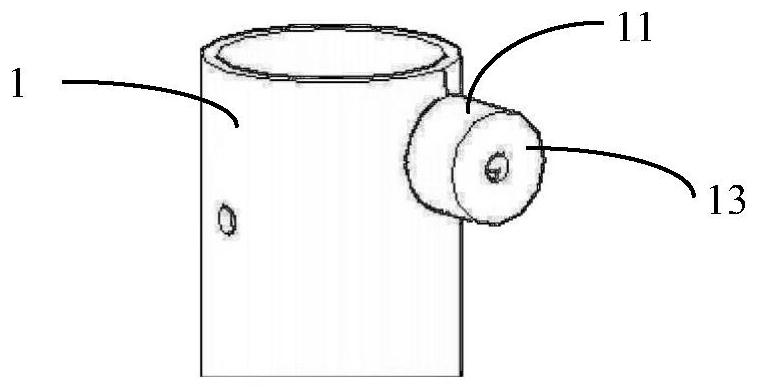

[0035] see Figures 1 to 7 , the embodiment of the present invention provides a quick installation lifeline device, which mainly includes an outsourcing pole 1, a supporting stand 2, a number of first rotating bearings 5, a number of second rotating bearings 6, and a buckle structure 3. Wherein, the outsourcing vertical rod 1 can be made of an inner hollow steel pipe, the bottom of which is closed by the steel pipe bottom plate 15 , and the outer periphery of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com