Wire harness goods shelf anti-winding mechanism

An anti-winding, wire harness technology, applied in thin material handling, storage devices, transportation of filamentous materials, etc., can solve problems such as damage to the wire harness automatic terminal crimping machine, affecting production efficiency, cable breaking, etc., to reduce the number of wires. The effect of the automatic terminal crimping machine that the cable is broken or damaged, and the work efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creation features, achievement goals and effects of the present invention easy to understand and understand, the present invention is further described below with reference to the accompanying drawings and embodiments.

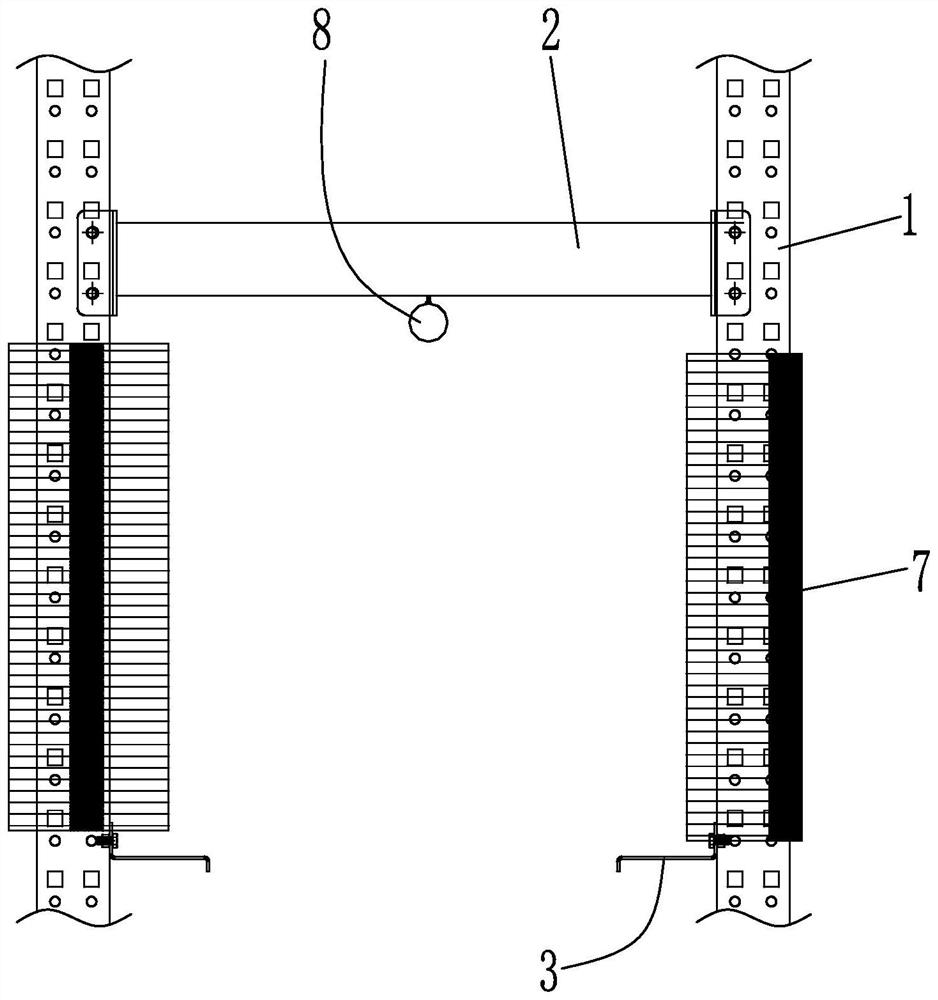

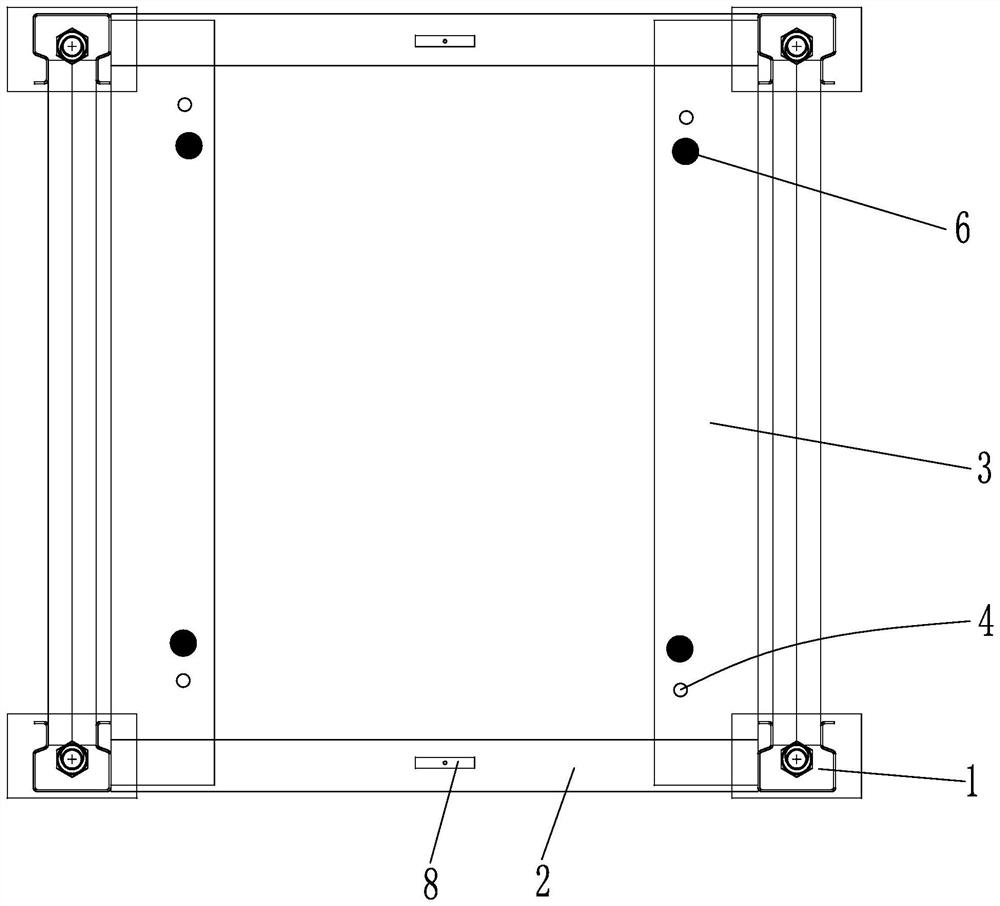

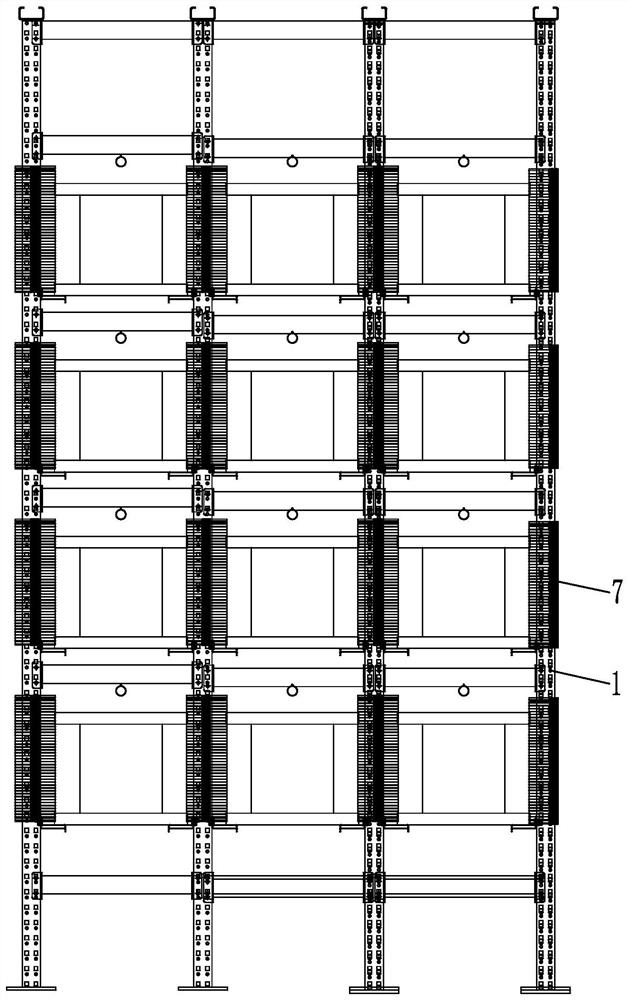

[0023] like Figure 1 to Figure 3 As shown, an anti-winding mechanism for a wire harness rack includes four uprights 1 and two beams 2 . The two beams 2 are horizontally welded on the front and rear sides of the four uprights 1 , the four uprights 1 and the two crossbeams 2 are welded to each other to form a vertical storage space, and several vertical storage spaces form a shelf. A vertical warehouse slot corresponds to a wire harness. Two storage boards 3 for placing wire harnesses are provided on the bottom of each vertical storage space and between the uprights 1 on the left and right sides. The two storage boards 3 together constitute a tray for placing wire harnesses. The two storage boards 3 are correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com