Horizontal geological survey equipment adopting coiled tubing and coring method

A technology of horizontal geology and coiled tubing, applied in the direction of earthwork drilling and extracting undisturbed core devices, etc., can solve problems such as difficulties in core drilling tools, improve the efficiency of horizontal core drilling, solve low efficiency, and save processing and manufacturing cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to more fully understand the technical content of the present invention, the technical solutions of the present invention are further introduced and described below with reference to specific embodiments, but are not limited thereto.

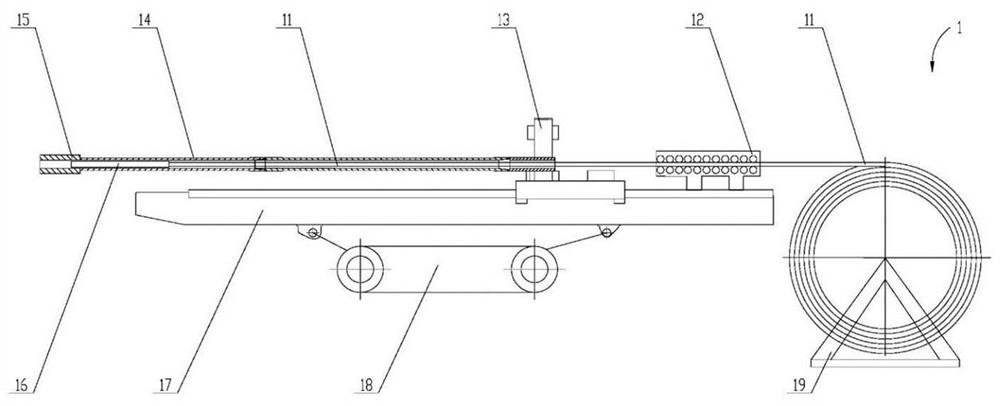

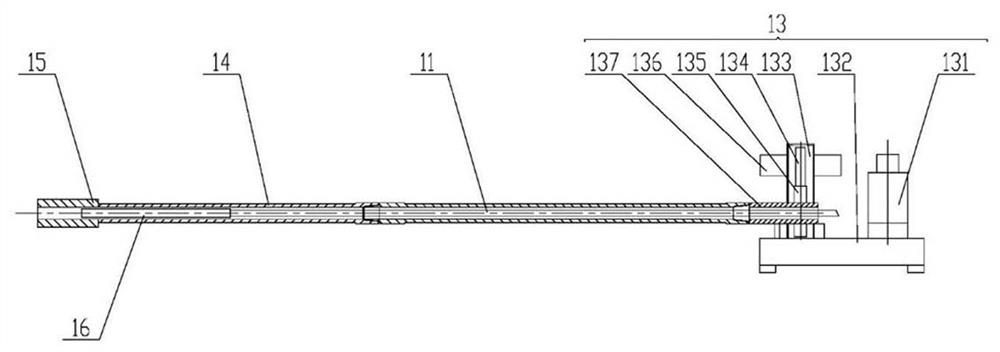

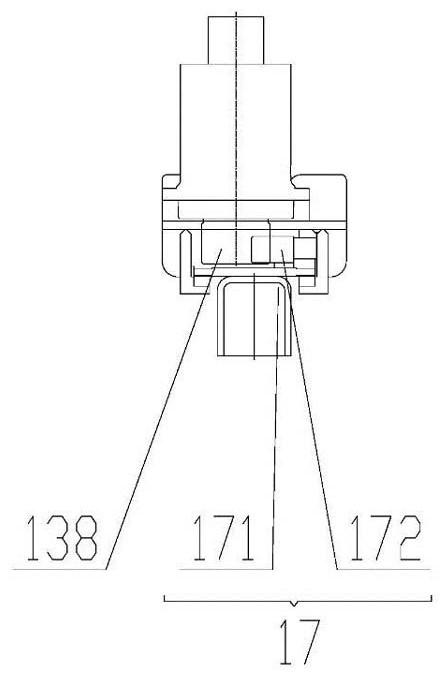

[0040] like Figure 1 to Figure 9 The illustrated embodiment provides a horizontal geological survey equipment using coiled tubing, including: coiled tubing 11, conveying mechanism 12, power head assembly 13, outer drill pipe 14, outer drill bit 15, coring equipment 16, drilling frame 17, Chassis 18, reel assembly 19, continuous pipe wall 111, wire harness 112, conveyor frame 121, clamping cylinder 122, roller 123, roller motor 124, push-pull motor 131, push-pull box 132, rotating box 133, rotating pinion 134. Large rotating gear 135, rotating motor 136, rotating main shaft 137, push-pull pinion 138, coring drill 161, coring barrel 162, mud motor 163, spearhead 164, slide rail 171, rack 172, reel motor 191, reel 192, support fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com