Concave shaping device for end part of linear motor coil

A coil end, linear motor technology, used in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problem of improving the safety protection effect of inconvenient devices, improving the stability effect of inconvenient devices, and clamping and fixing inconvenient device parts, etc. problems, to achieve the effect of improving the effect of processing illumination, improving the convenience of automation, and improving the effect of safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

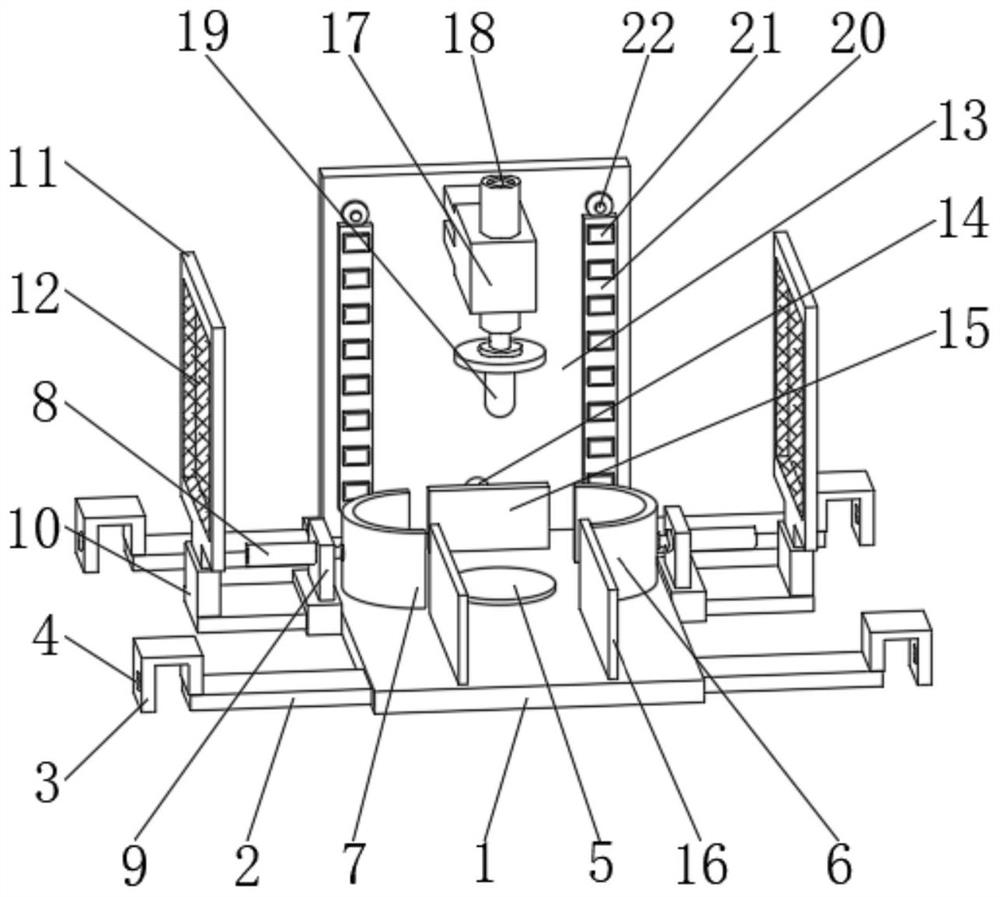

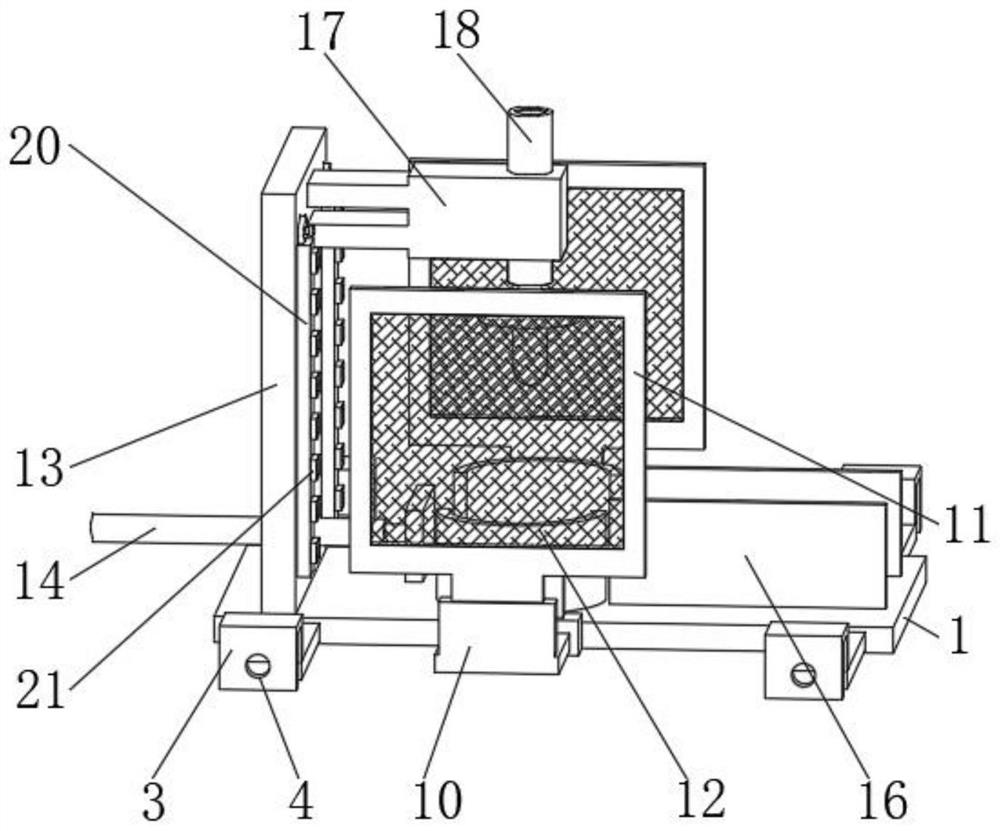

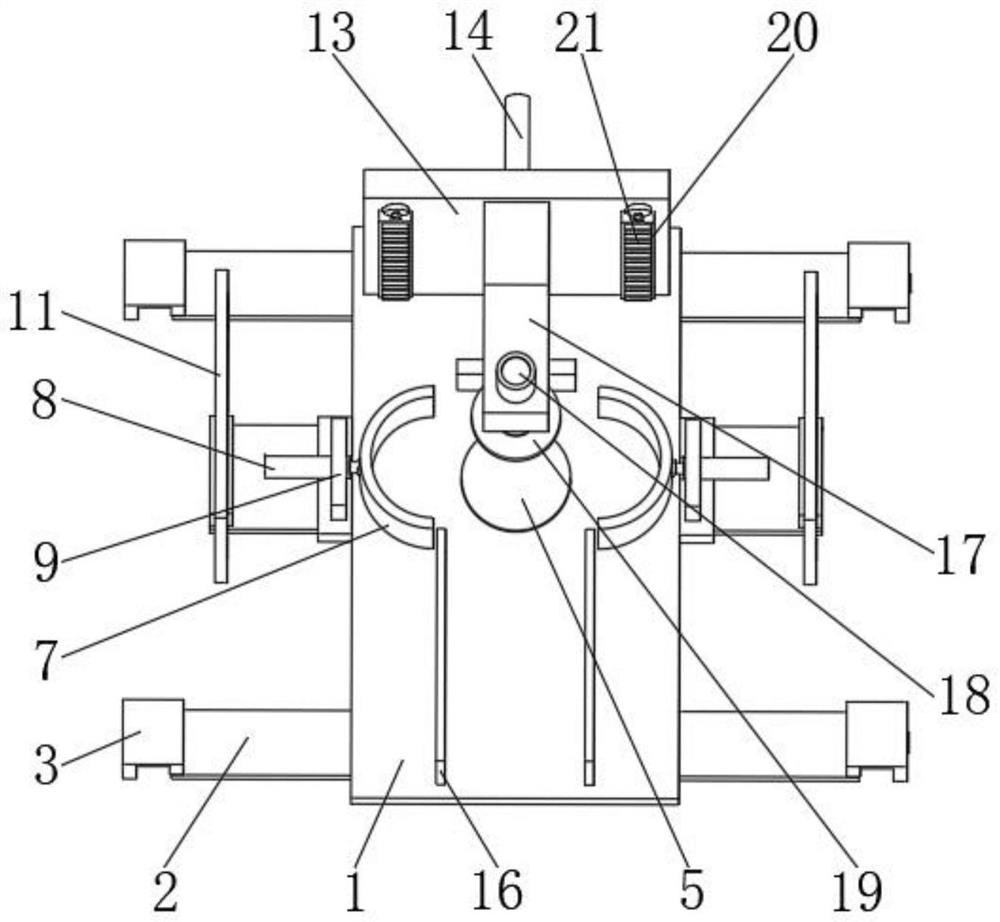

[0027] see figure 1 and Figure 5 As shown, a concave shaping device for the coil end of a linear motor includes a base 1, a connecting plate 10 and a back plate 13. An extension plate 2 is provided on the side of the base 1, and the end of the extension plate 2 is provided with a connecting plate 3. , and the inner side of the connecting plate 3 is provided with a fixing hole 4, the middle position of the base 1 is provided with a positioning plate 5, and the side of the positioning plate 5 is provided with a first arc-shaped plate 6, and the first arc-shaped plate 6 is about the positioning plate 5. The other side is provided with a second arc-shaped plate 7, and the side of the second arc-shaped plate 7 is fixedly connected with an electric telescopic rod 8, and the outer side of the electric telescopic rod 8 is provided with a fixed plate 9, and the connecting plate 10 is arranged on the extension A fixing frame 11 is provided on the side of the board 2 and on the top of ...

Embodiment 2

[0032] see Figure 1-4 As shown in the comparison example 1, as another embodiment of the present invention, the back plate 13 is arranged on the back of the base 1, and the inner side of the back plate 13 is penetrated by a hydraulic rod 14, and the end of the hydraulic rod 14 is provided with a push plate 15, and the side of the push plate 15 is provided with a limit plate 16 that is fixedly connected to the base 1, the middle position of the outer wall of the back plate 13 is provided with a fixed seat 17, and the middle position of the end of the fixed seat 17 is provided with a lifting rod 18, And the end of the lifting rod 18 is fixedly connected with the shaping head 19, the side of the fixing seat 17 is provided with a sticking board 20, and the outer wall of the sticking board 20 is provided with a lighting lamp 21, and the top of the sticking board 20 is provided with the back plate 13. Attached set screw 22.

[0033] The push plate 15 forms a lifting structure with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com