Automatic splicing device for yarn changing

A yarn and automatic technology, applied in the field of yarn changing automatic splicing device, can solve the problems of wasting human resources, yarn disconnection, yarn breaking, etc., and achieve the effect of avoiding untimely changing of yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

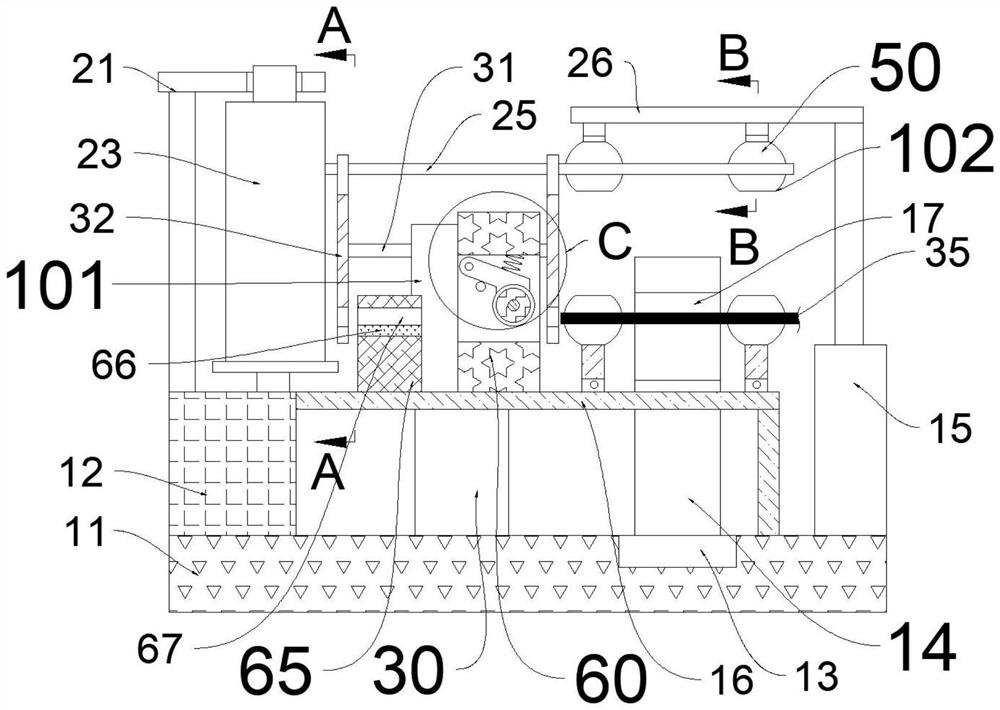

[0019] The present invention will be further described below in conjunction with the accompanying drawings:

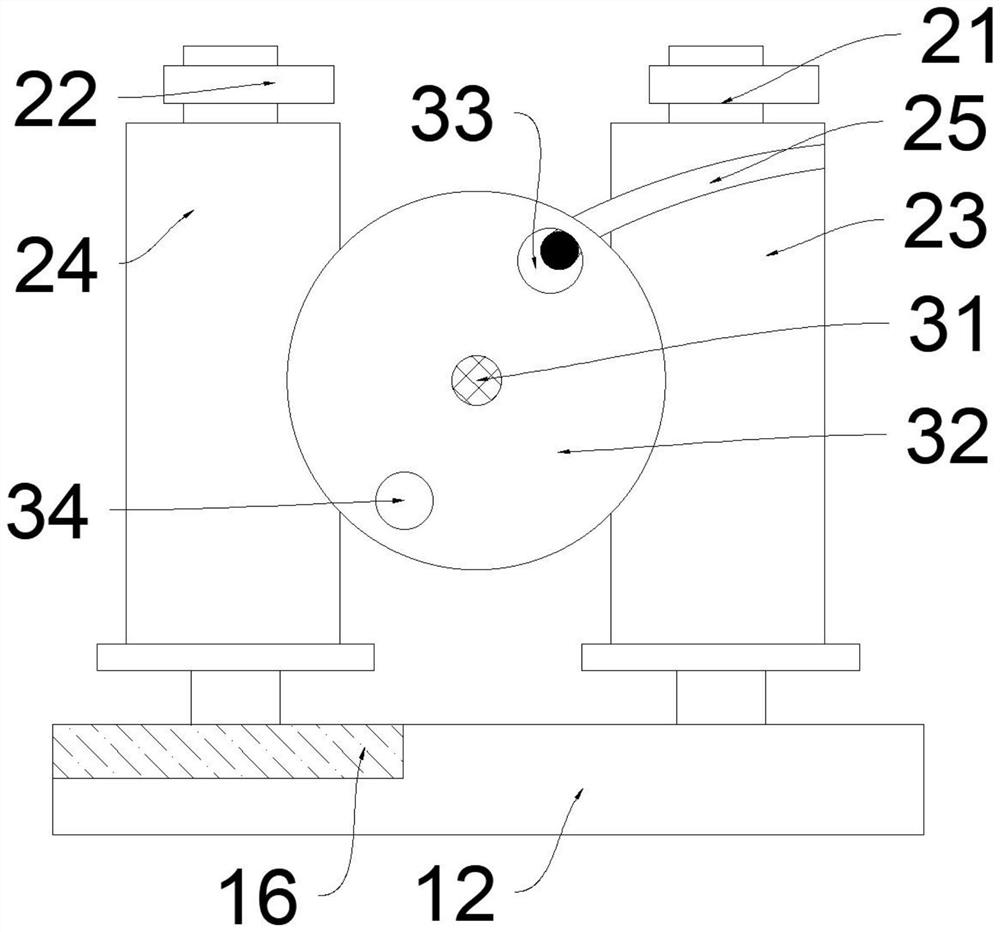

[0020] A yarn changing automatic splicing device, such as Figure 1-4 As shown, it includes a base 11, a pedestal 12, and a bracket 16. The pedestal 12 is fixed on the base 11, the bracket 16 is fixed on the side of the pedestal 12, and the bracket 16 is fixed on the base. 11, a first bobbin seat 21 is fixed on the pedestal 12, a first bobbin 23 is mounted on the first bobbin seat 21, and a first bobbin is wound on the first bobbin 23. For the yarn 25, a second bobbin holder 22 is arranged on the side of the first bobbin holder 21, and a second bobbin 24 is installed on the second bobbin holder 22.

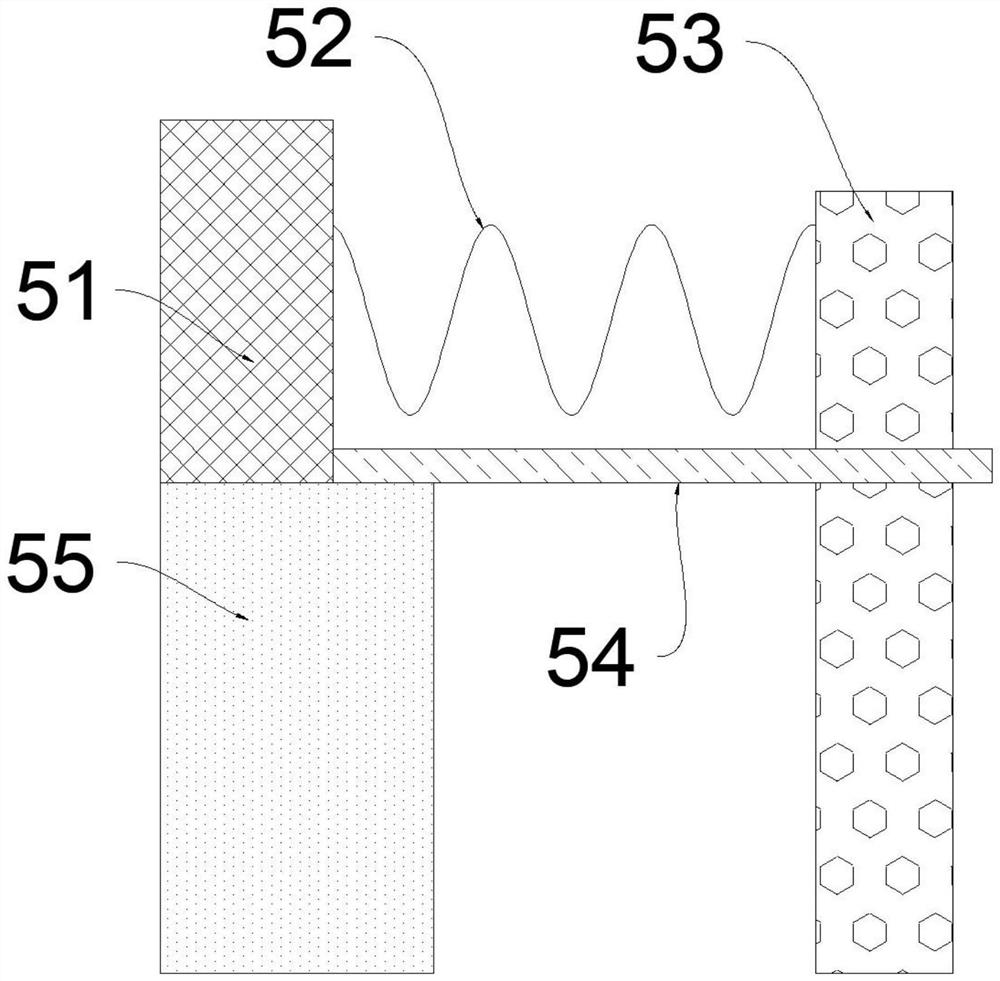

[0021] The base 11 is provided with a wire changing device 101, the wire changing device 101 includes a driving device 30, a driving shaft 31 is controlled on the driving device 30, and discs 32 are respectively fixed at both ends of the driving shaft 31 , the disc 32 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap