Recoverable bridge plug putting tool

A bridge plug and tool technology, used in the production of pipe string plugging tools and recyclable bridge plug delivery tools, can solve the problems of low general applicability and high cost of use, and achieve the effect of safe and effective delivery and setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the accompanying drawings.

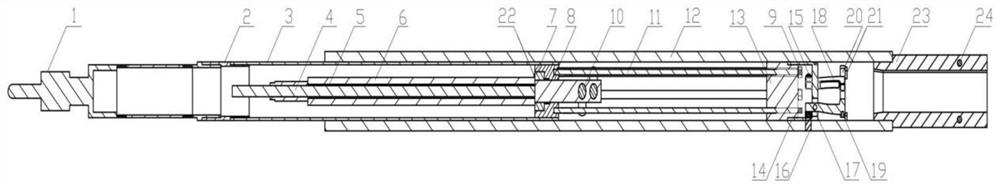

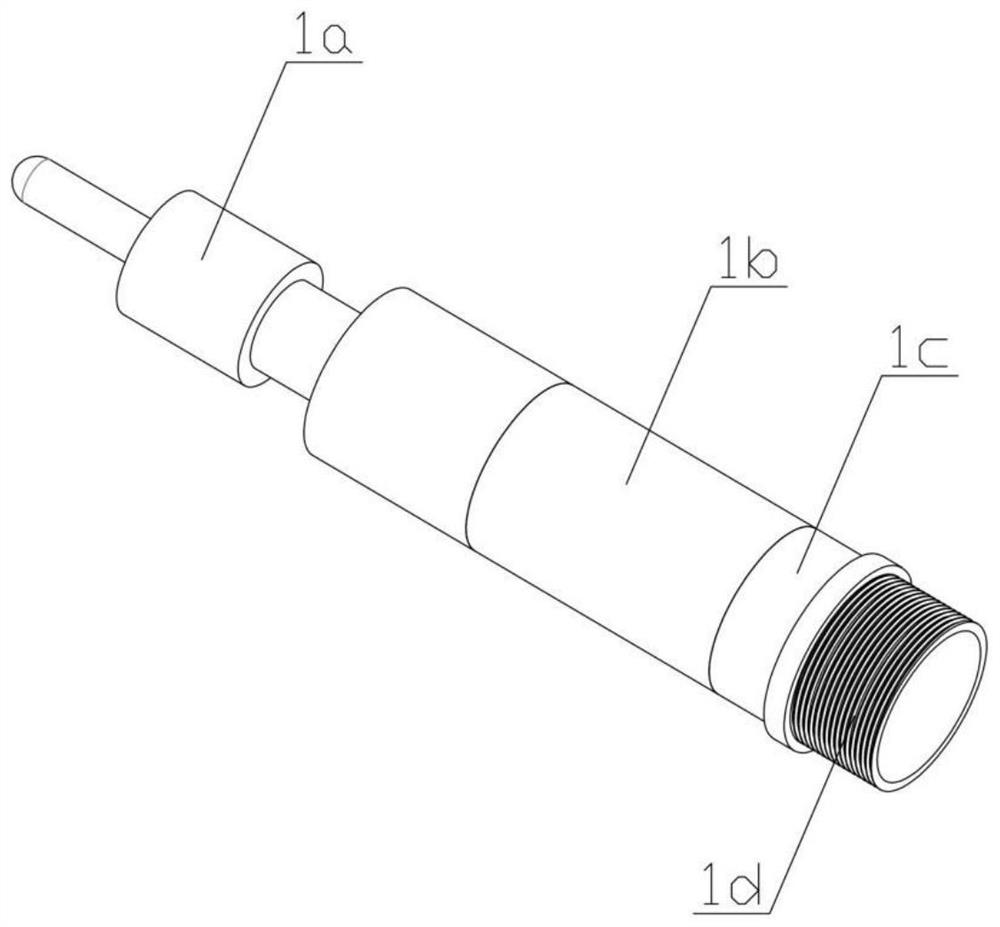

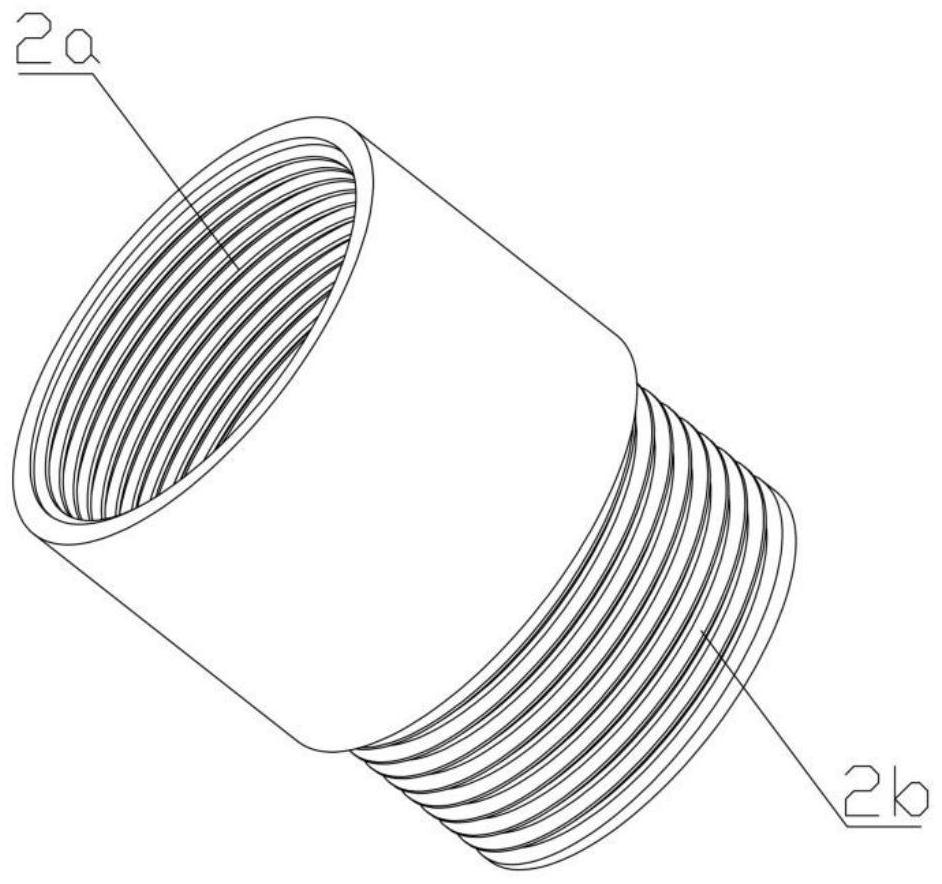

[0023] like Figure 1-Figure 8 As shown, a recyclable bridge plug throwing tool is composed of a cable joint 1, a conversion short section 2, a main sleeve 3, an electric cylinder mandrel 4, an electric cylinder mandrel sleeve 5, an electric cylinder column 6, and an electric cylinder sleeve 7 , threaded sleeve 8, electric cylinder fixing sleeve 9, transmission pin 10, transmission support column 11, outer sleeve 12, transmission column connection table 13, gripper drive table 14, gripper spring 15, spring plug 16, rotation The shaft 17 , the gripper 18 , the limit ring shear pin 19 , the gripper limiter ring 20 , and the clamping plate 21 are composed. It is characterized in that: the electric cylinder mandrel 4 and the electric cylinder mandrel sleeve 5 are threadedly connected, the casting tool is energized, and the electric cylinder mandrel 4 rotates, thereby drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com